Chemistry and Chemists № 1 2026

Journal of Chemists-Enthusiasts

| Content | Chemistry experiments - video | Physics experiments - video | Home Page - Chemistry and Chemists |

|

Chemistry and Chemists № 1 2026 Journal of Chemists-Enthusiasts |

Electrospinning - pt.26, 27 Chemist |

|

Having noticed a mistake in the text, allocate it and press Ctrl-Enter

Electrospinning: Solutions of Polystyrene and Polyvinylidene Difluoride in Dimethylformamide - Part 26

Despite my fatigue, I continued to think about my recent experiment after I got home. At first, I recalled and analyzed the events of New Year's Day; then, without realizing it, I began planning future work. Electrospinning polystyrene in DMF had yielded good results, which was a pleasant surprise. It would be logical to assume that the high electrical conductivity of DMF was the reason. However, electrospinning a PVDF solution in DMF had not produced fibers. Or rather, my physicist colleague had managed to obtain PVDF fibers by electrospinning a similar solution, whereas my own experiments had been unsuccessful. At that time, my colleague was still ill and was not expected to return to work in the near future.

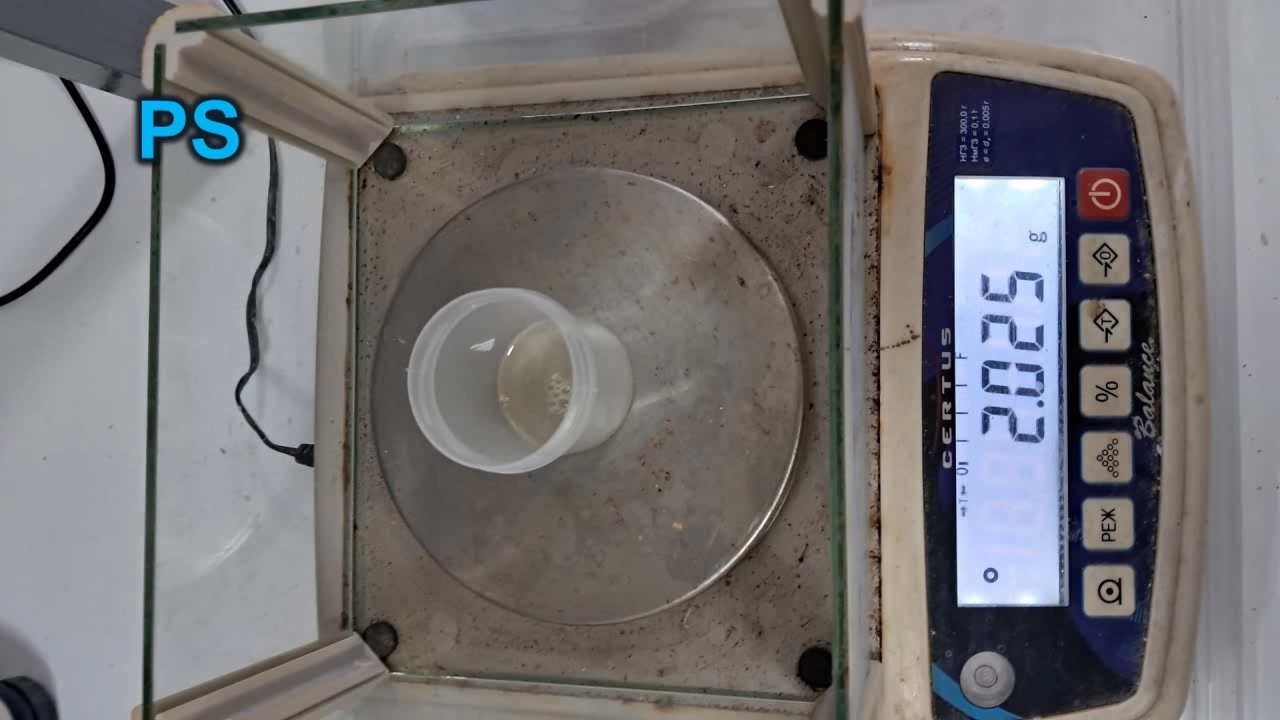

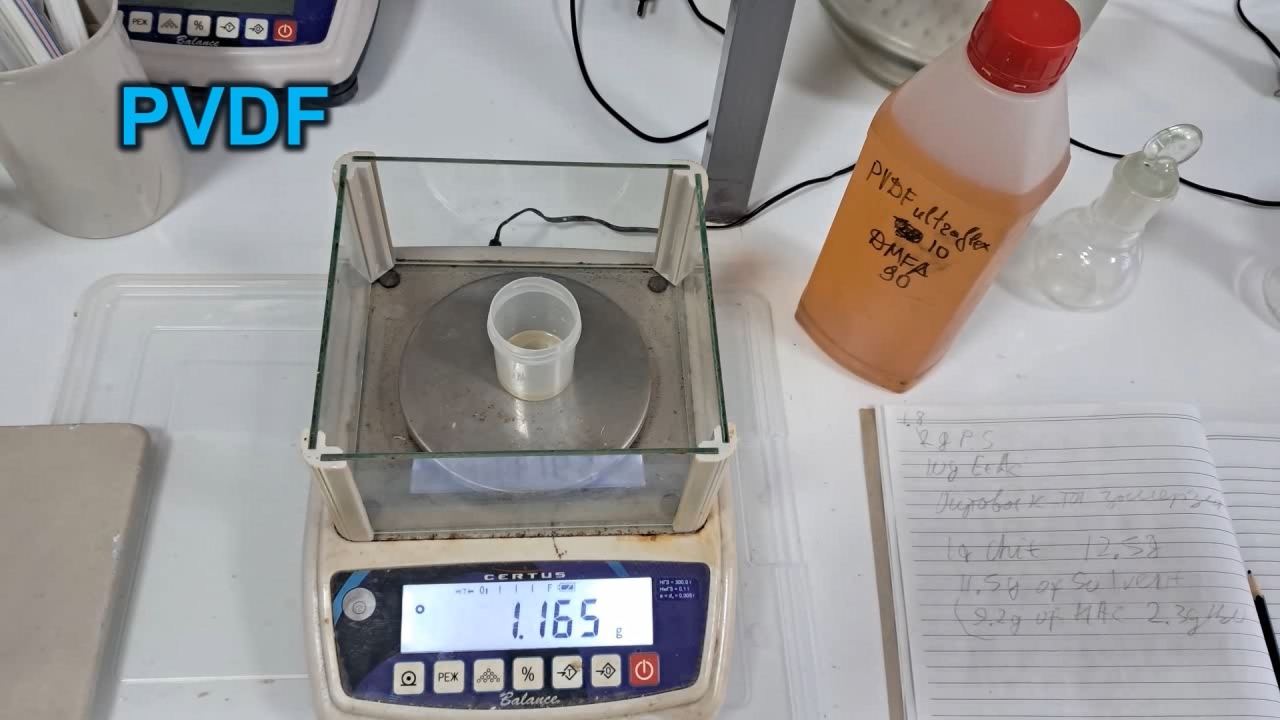

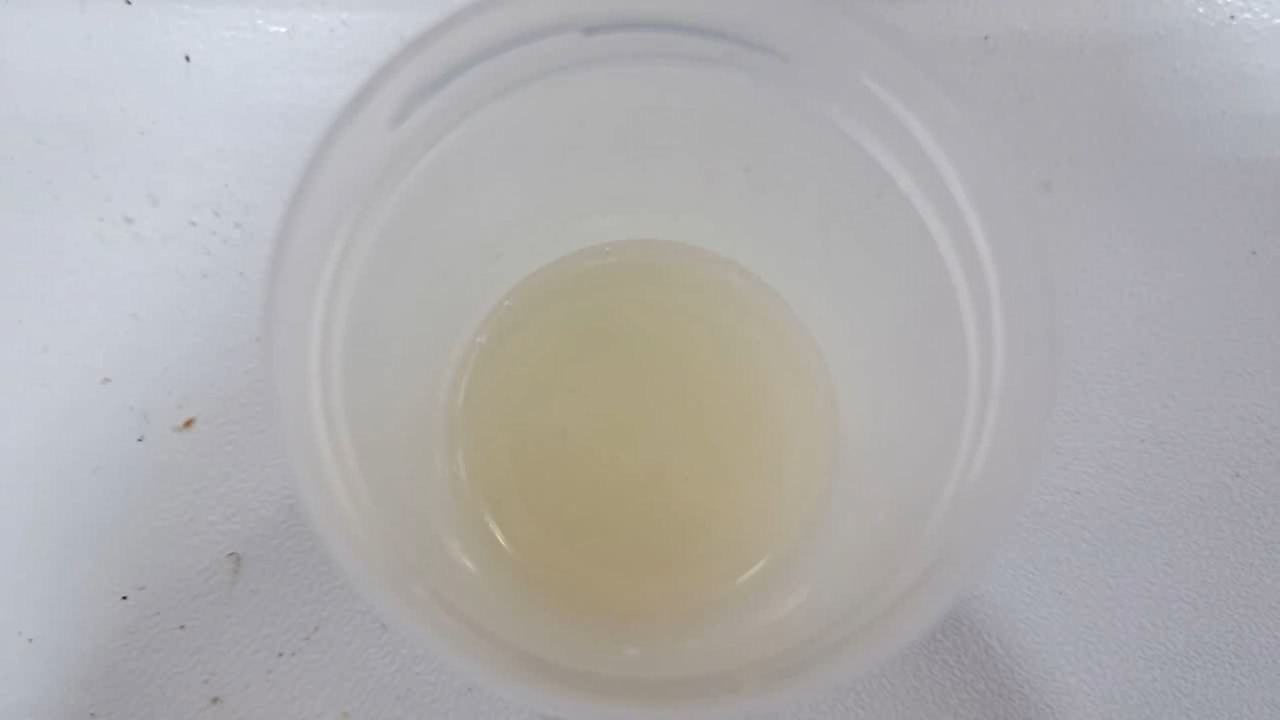

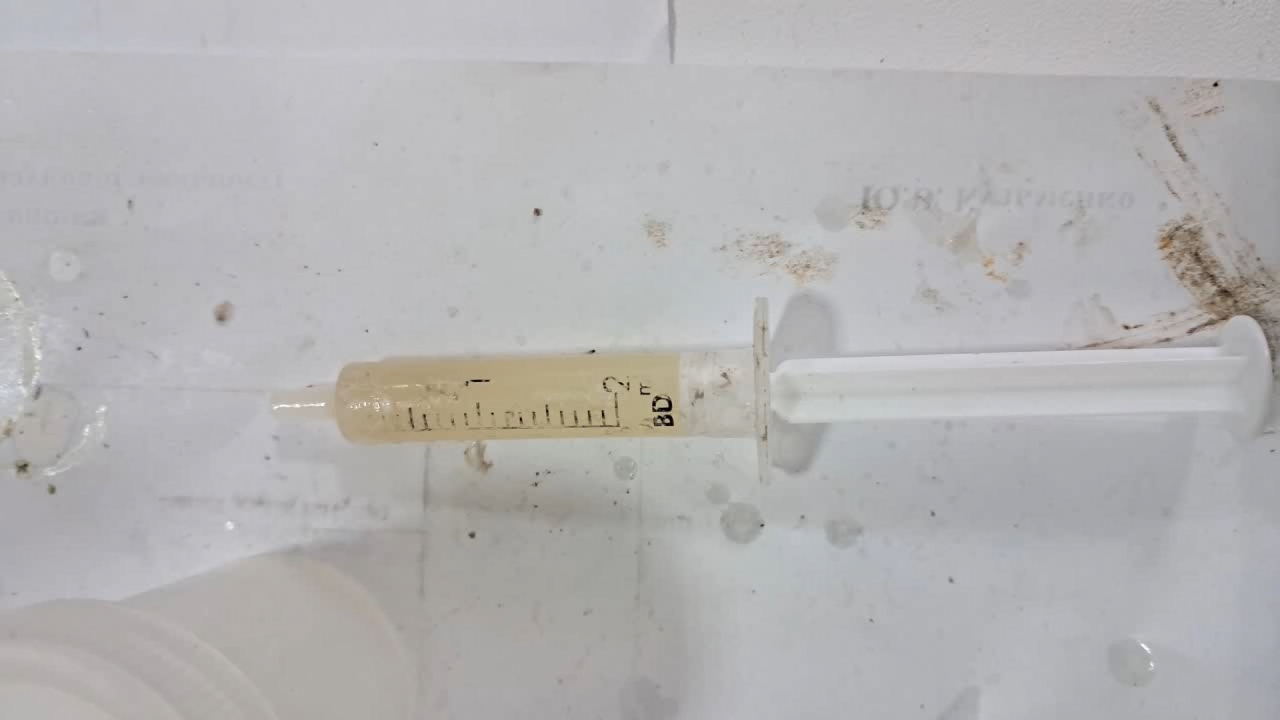

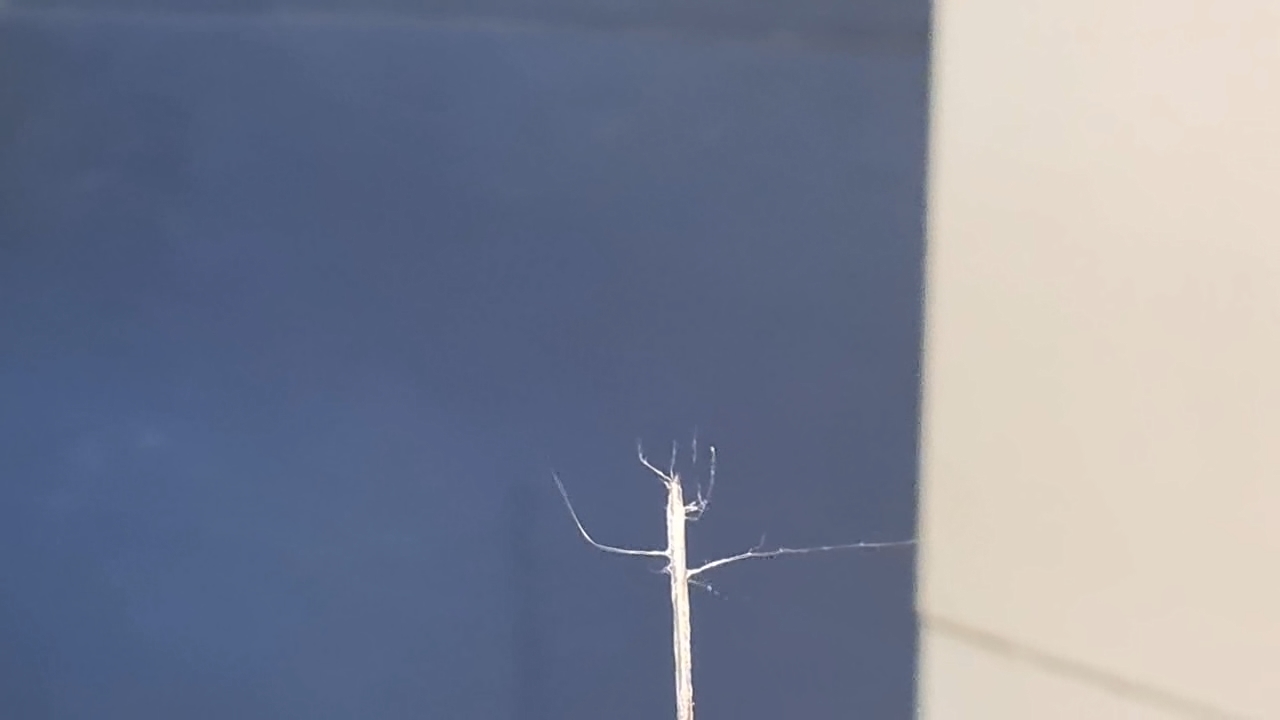

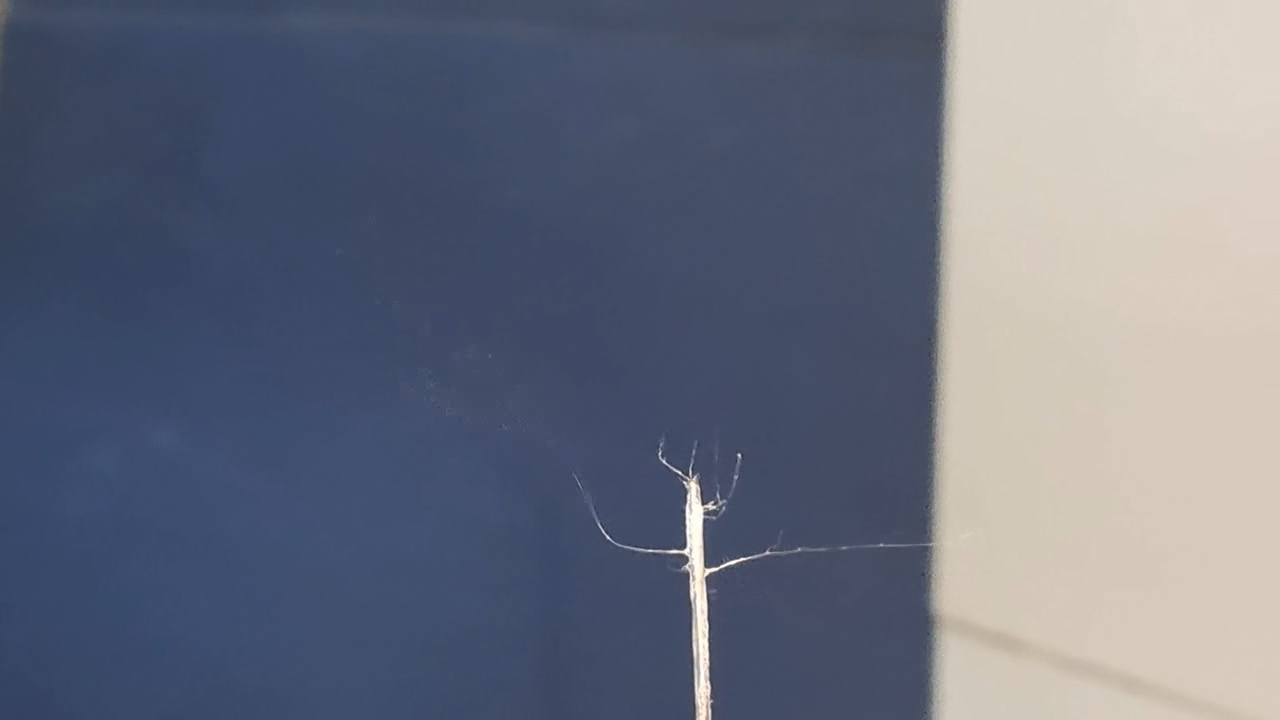

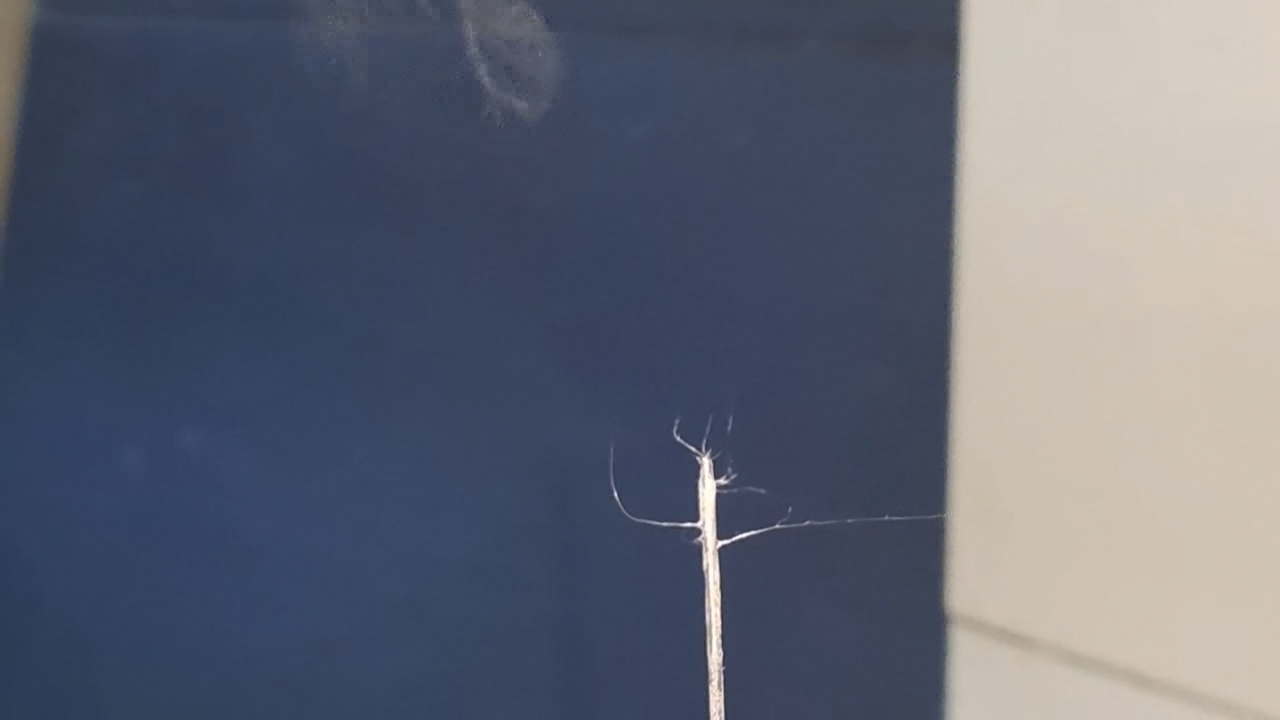

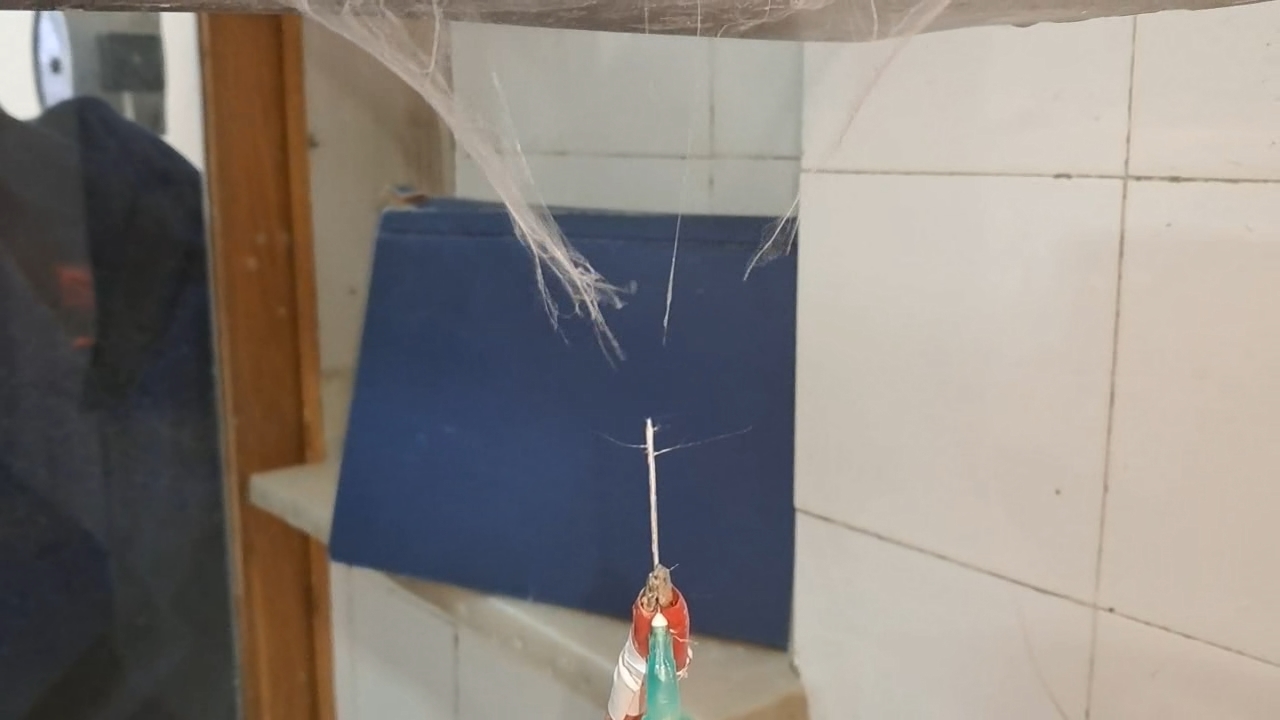

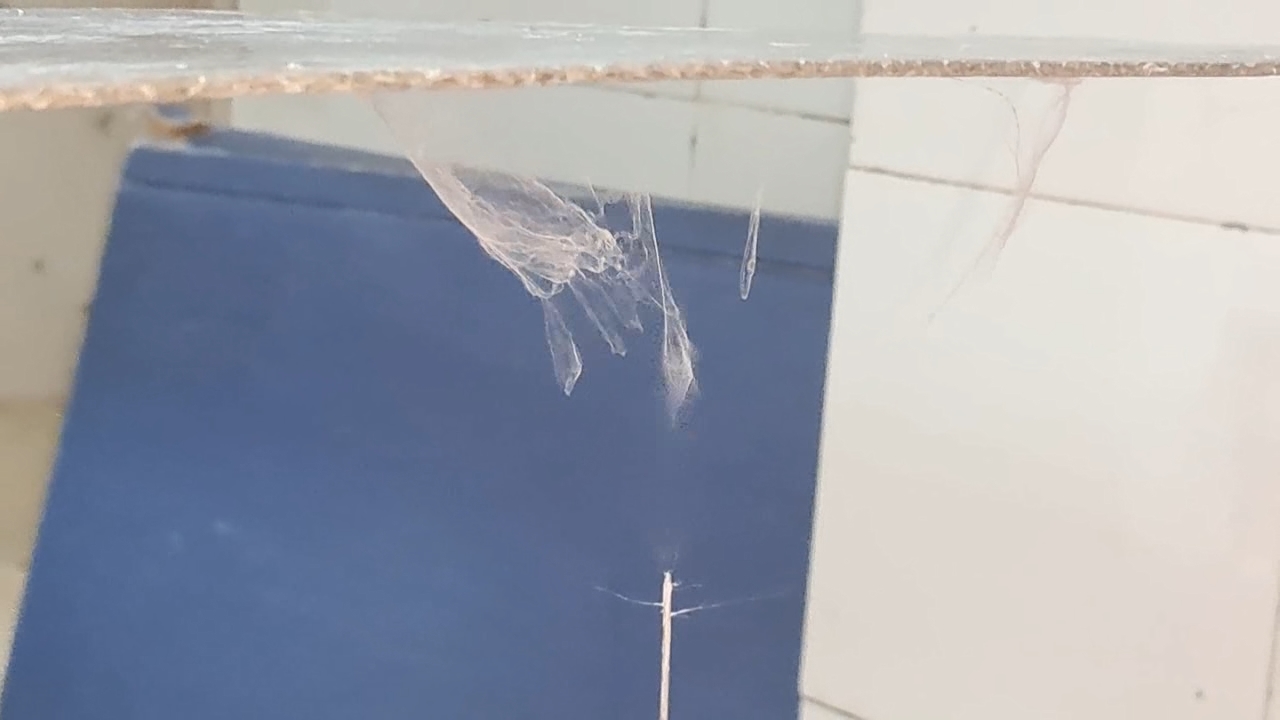

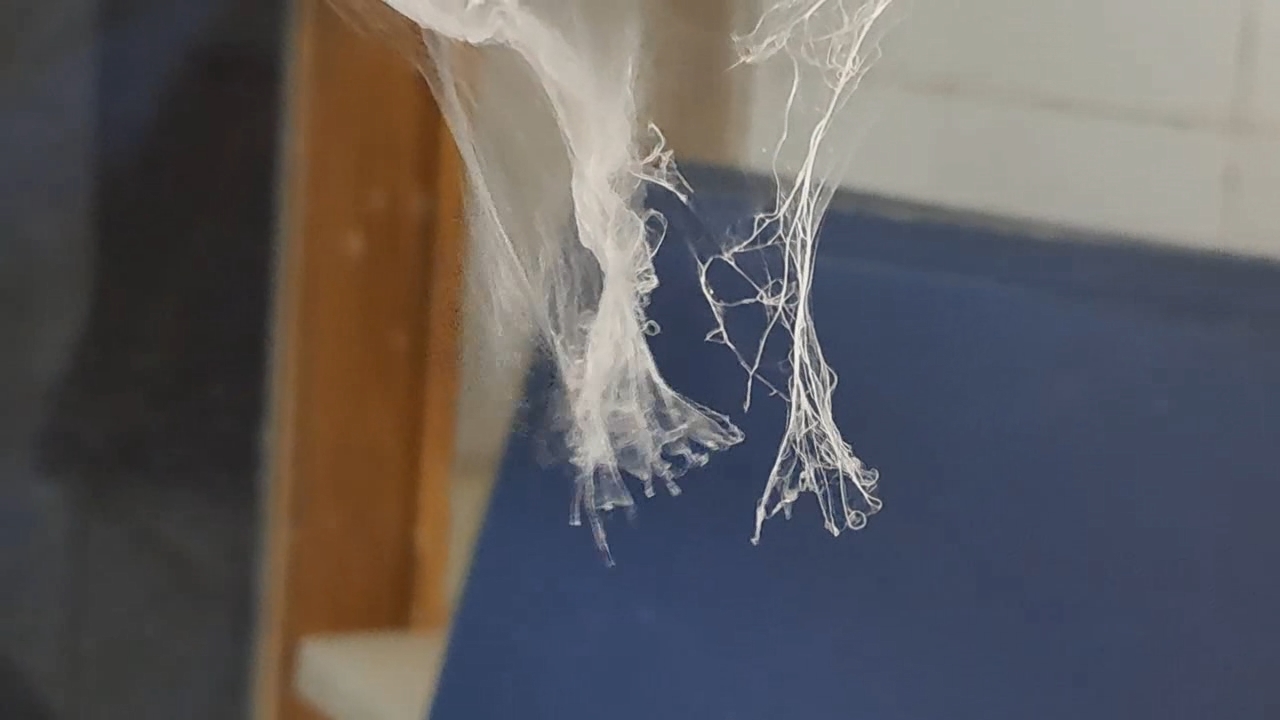

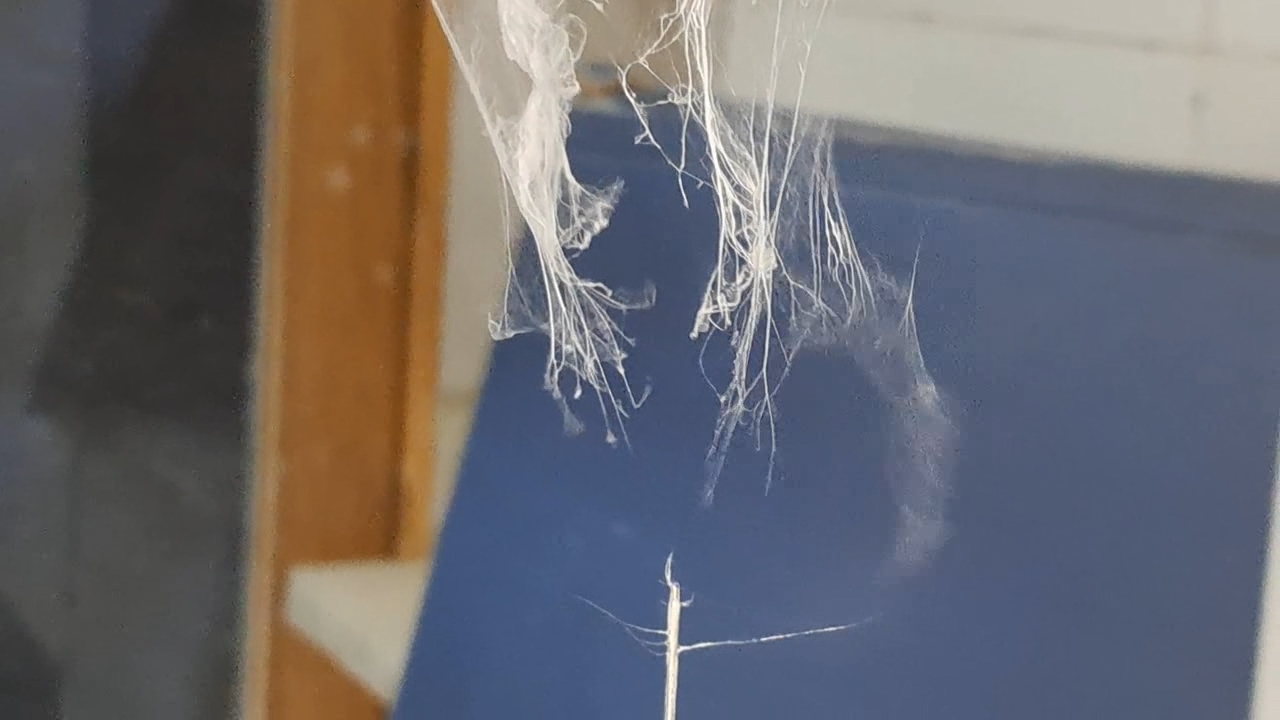

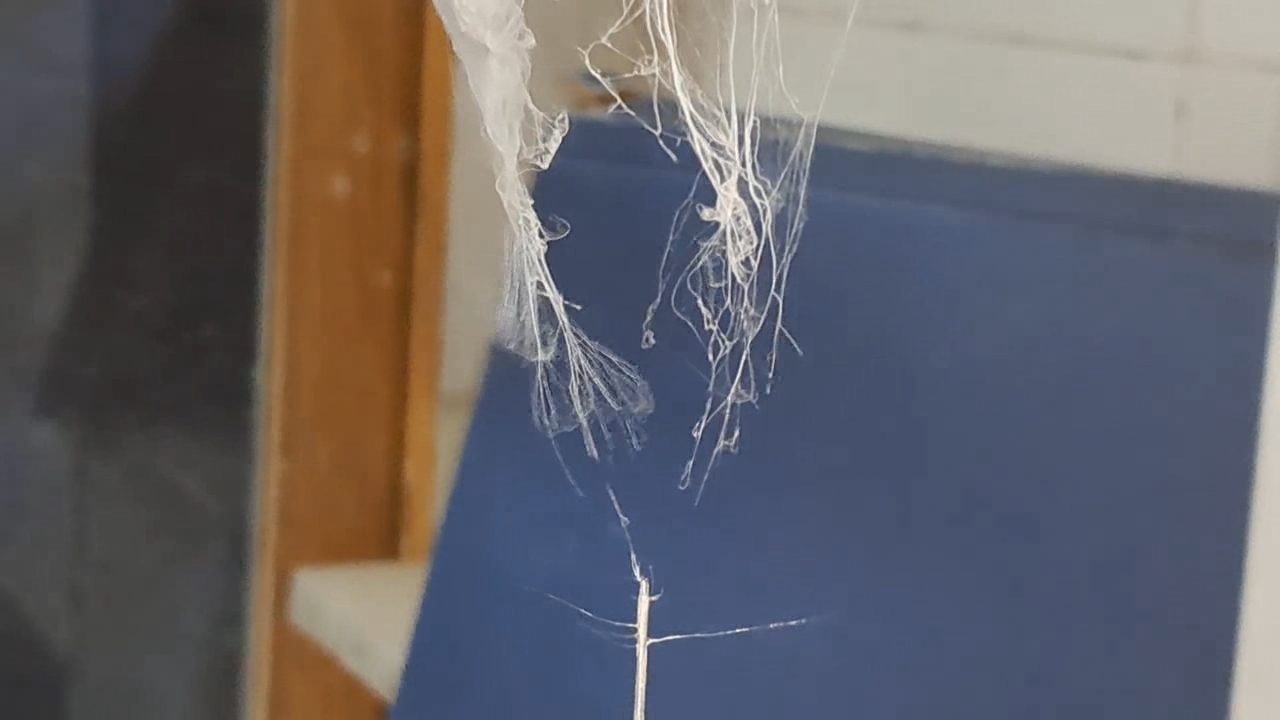

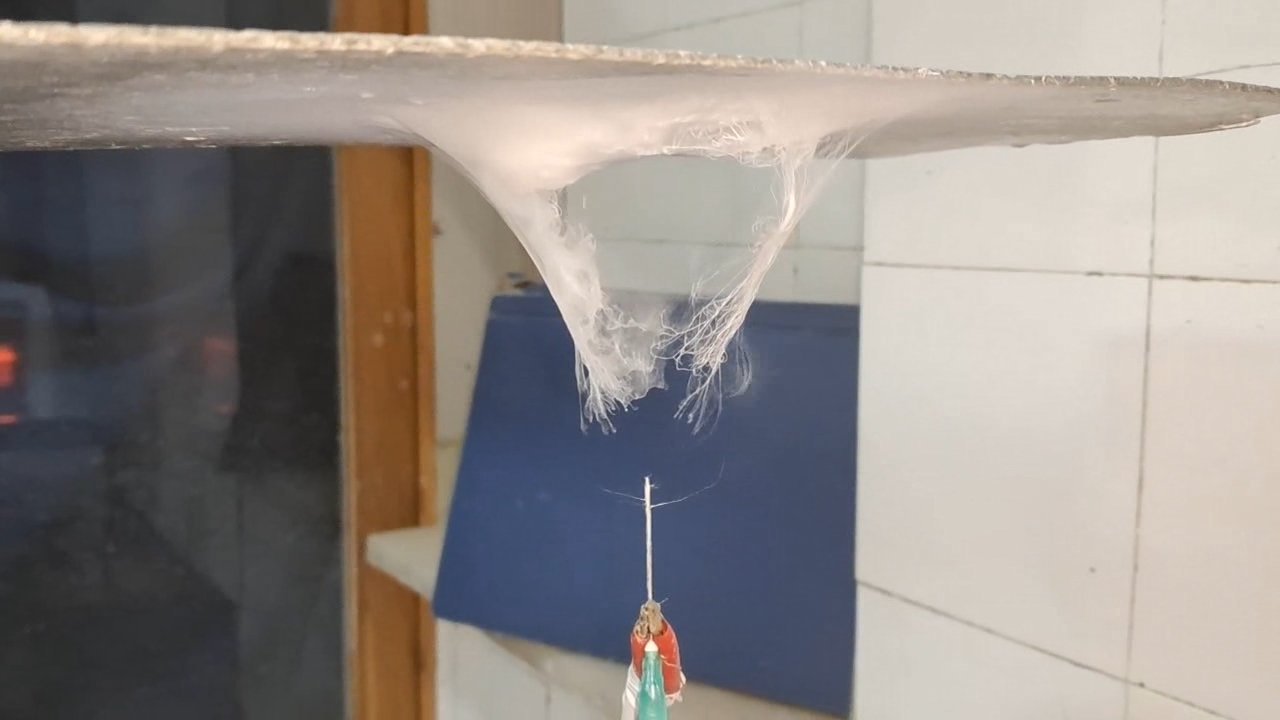

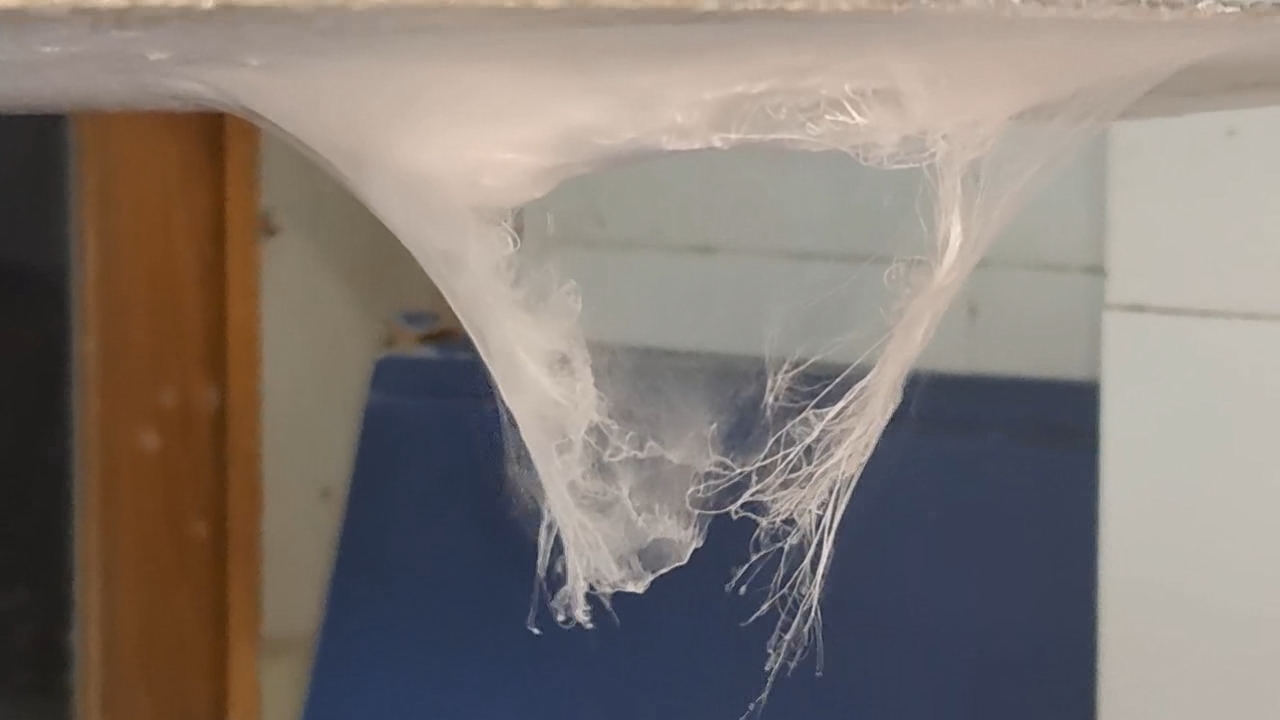

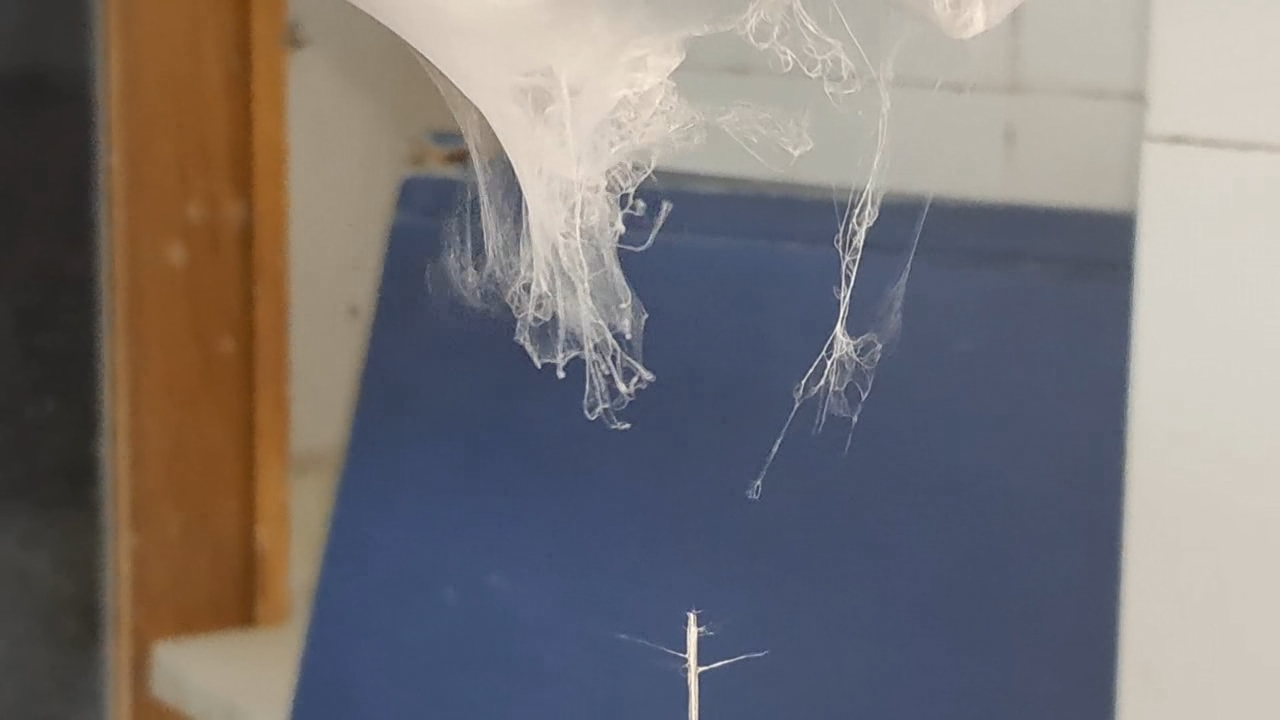

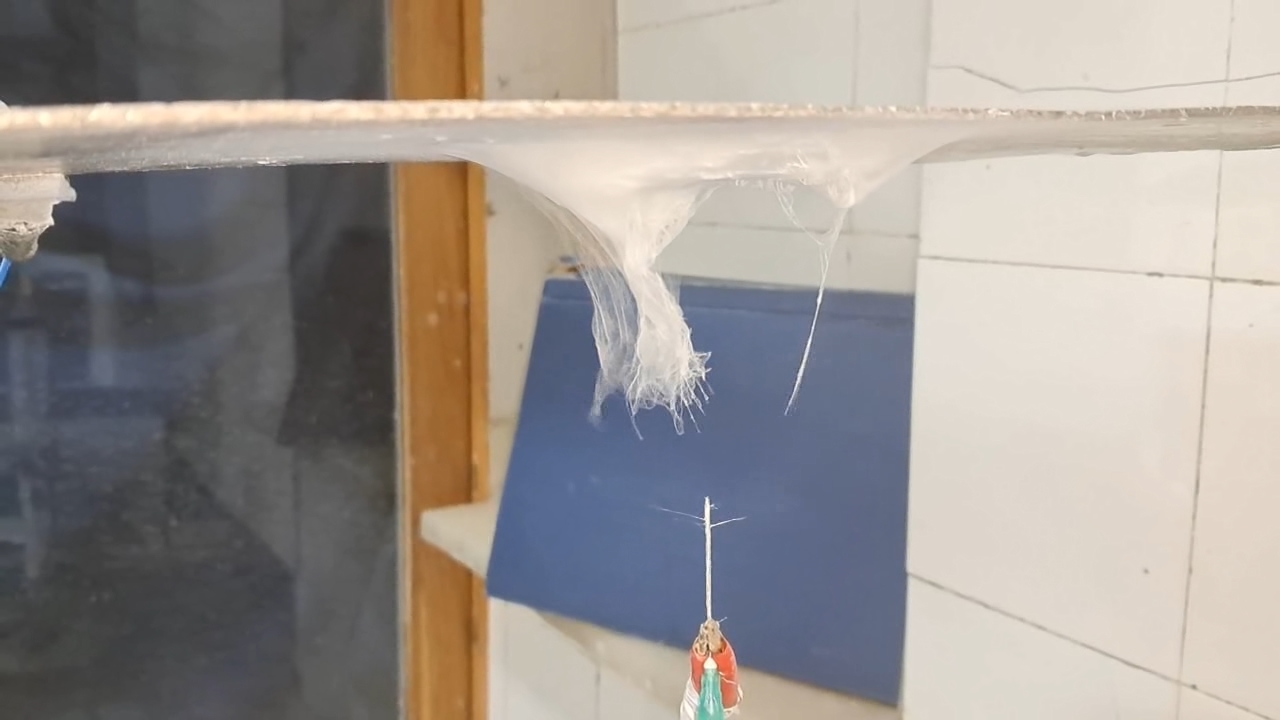

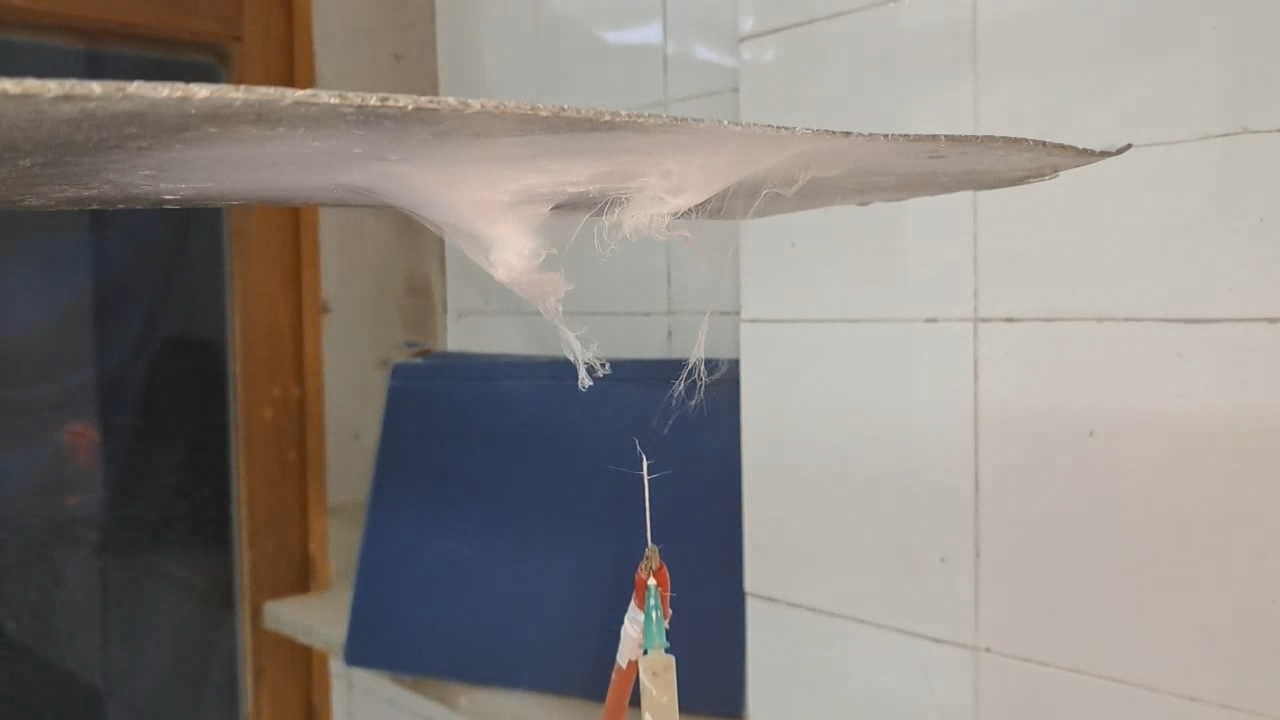

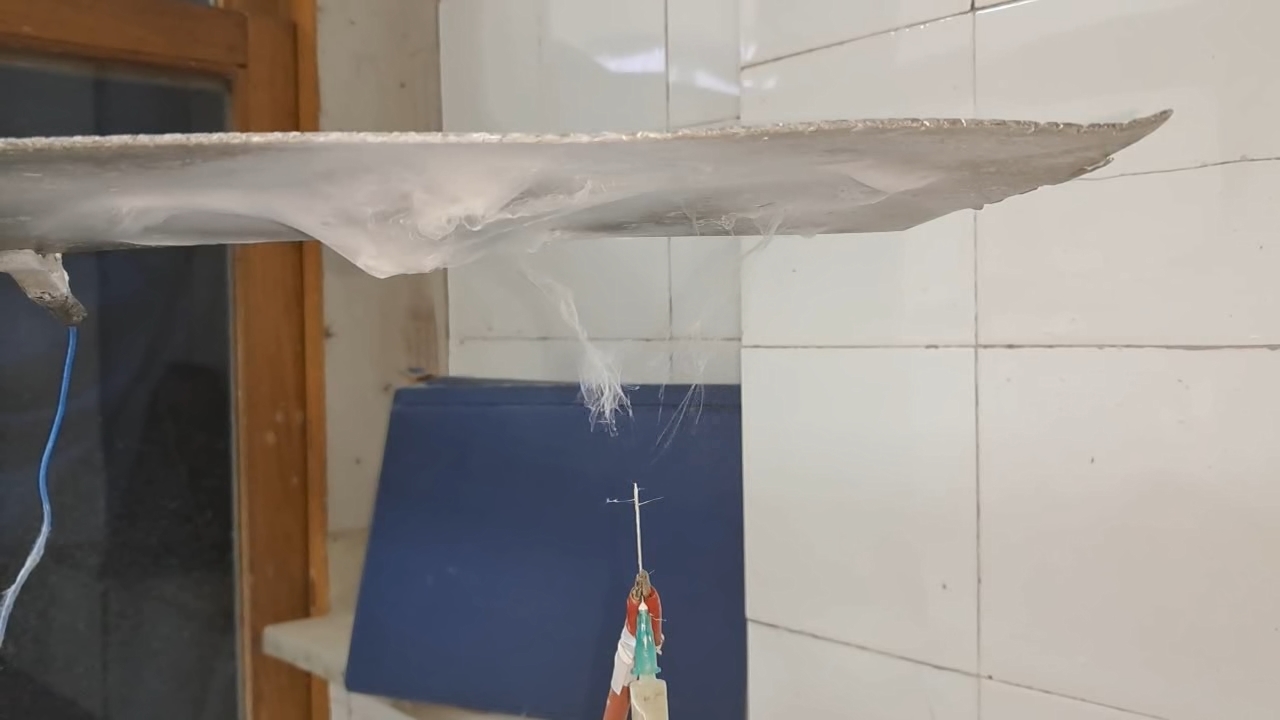

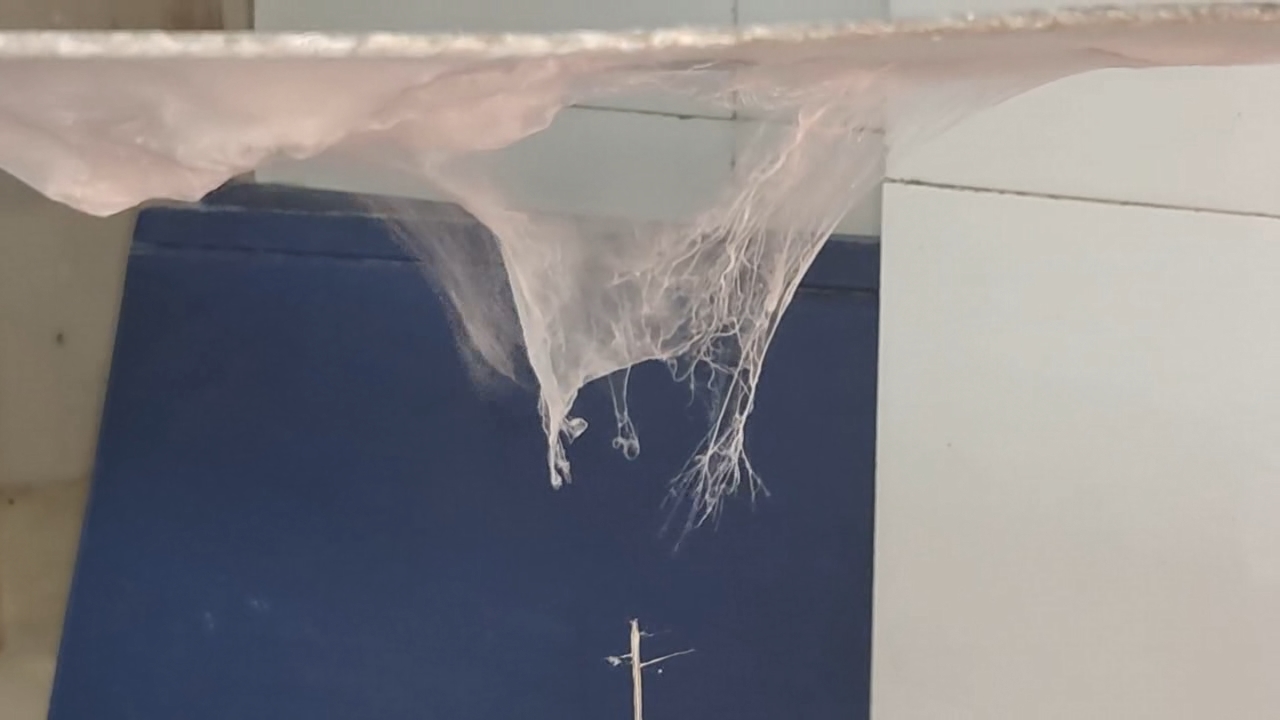

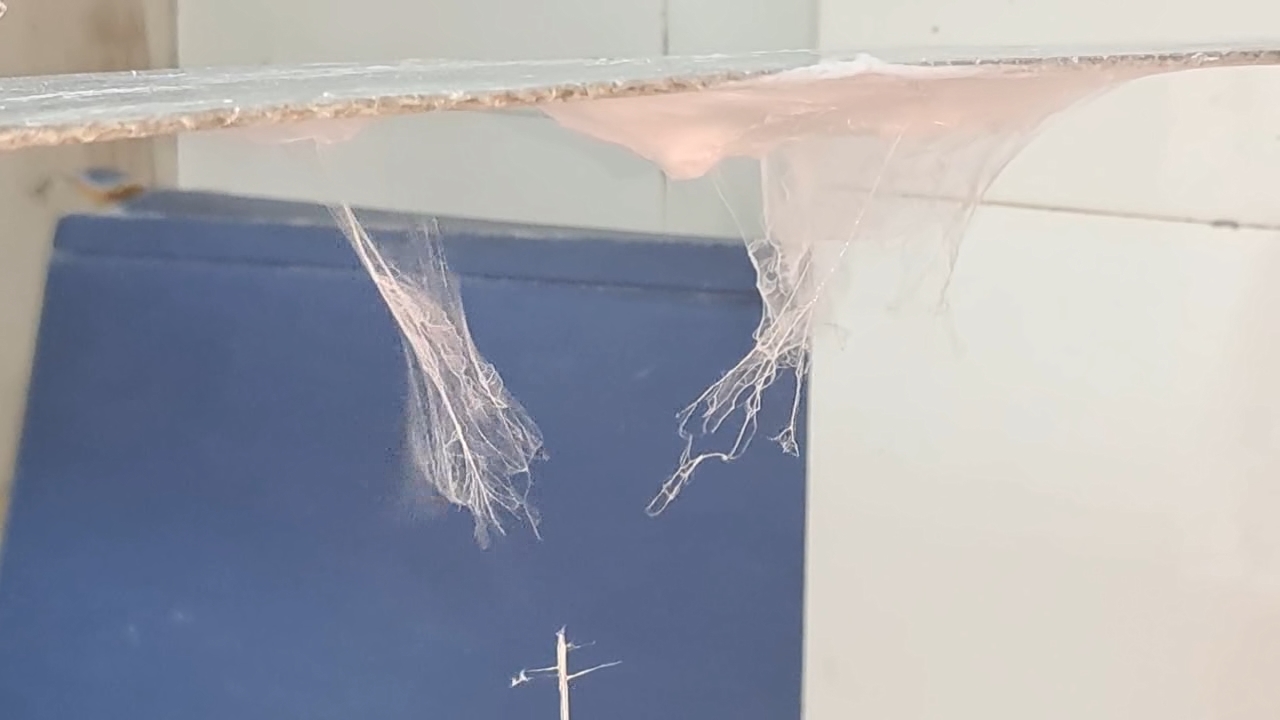

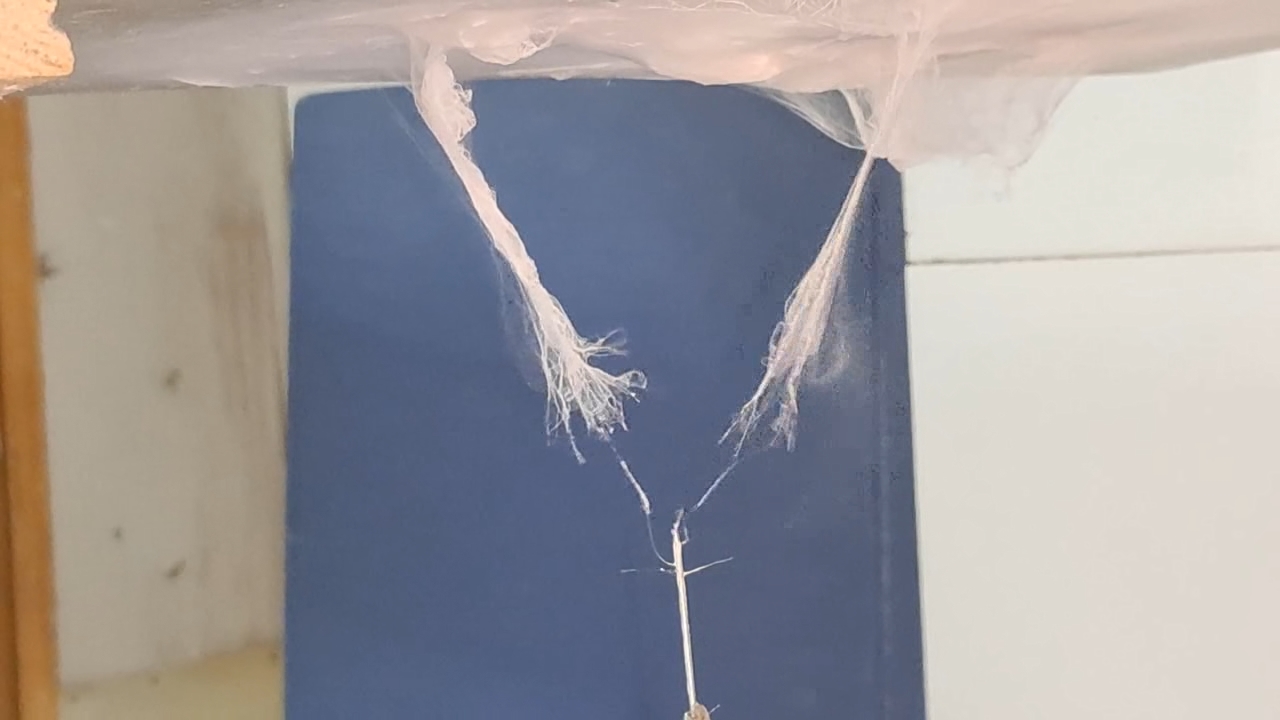

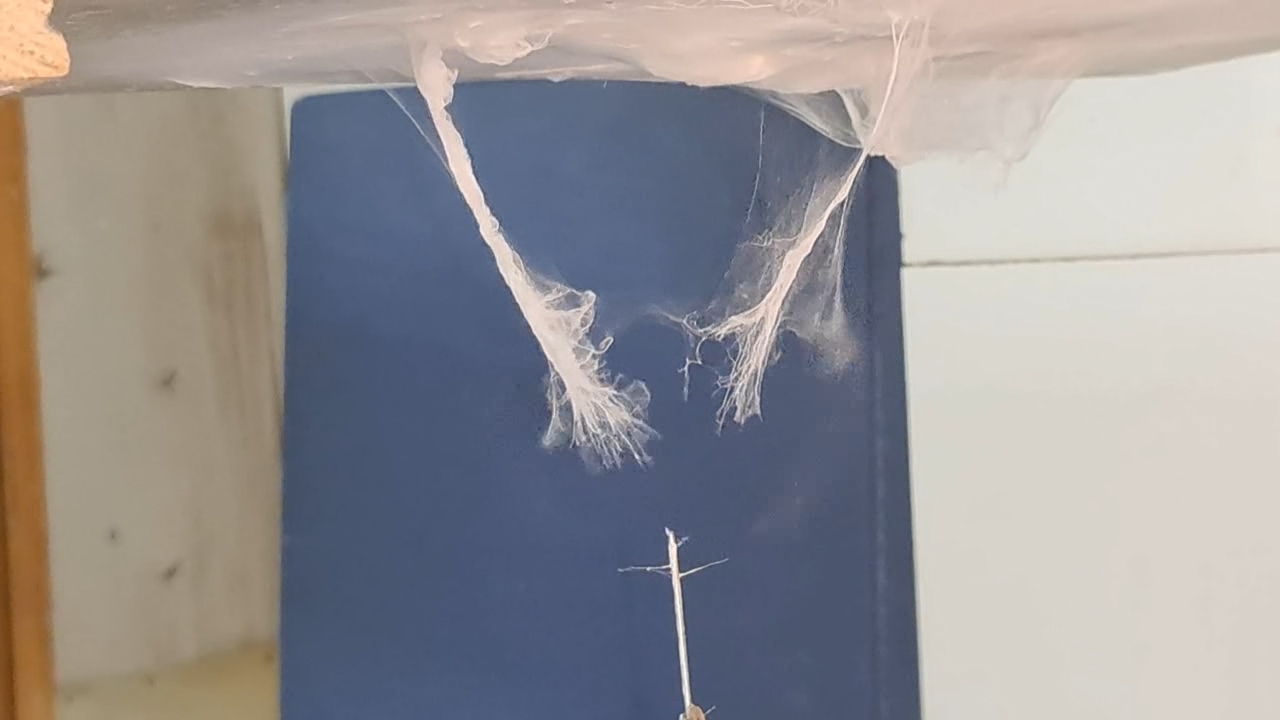

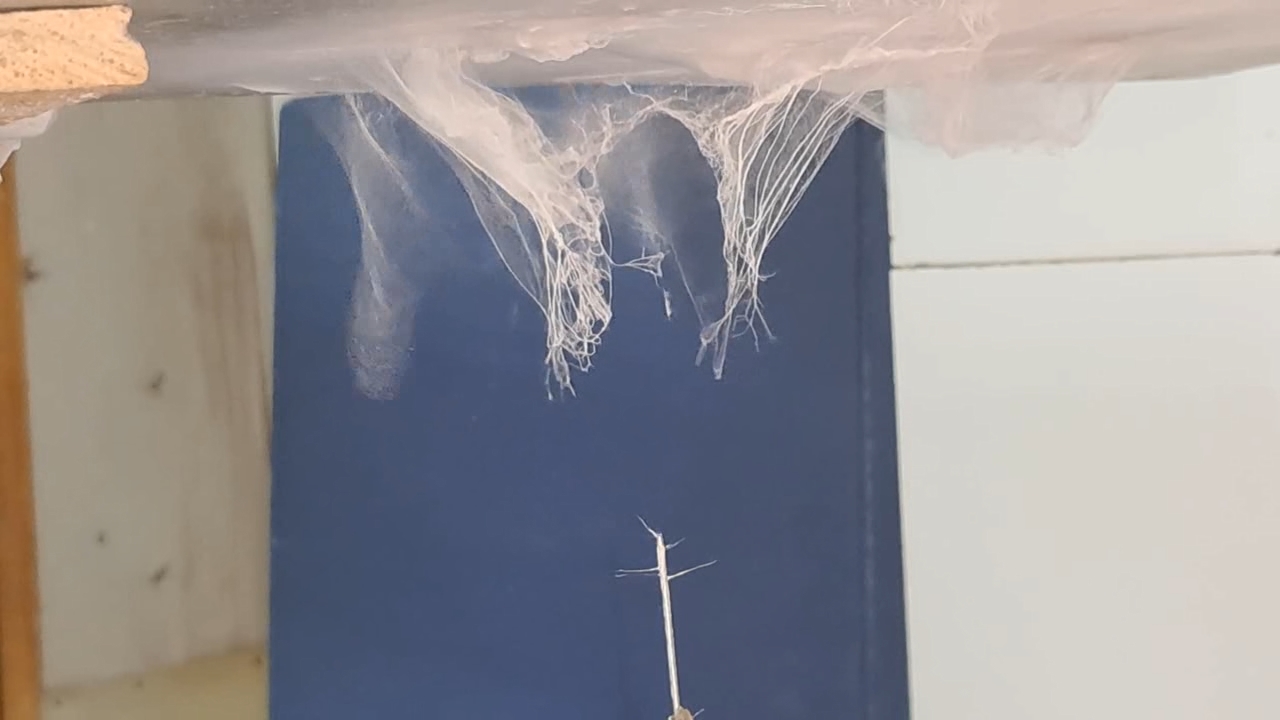

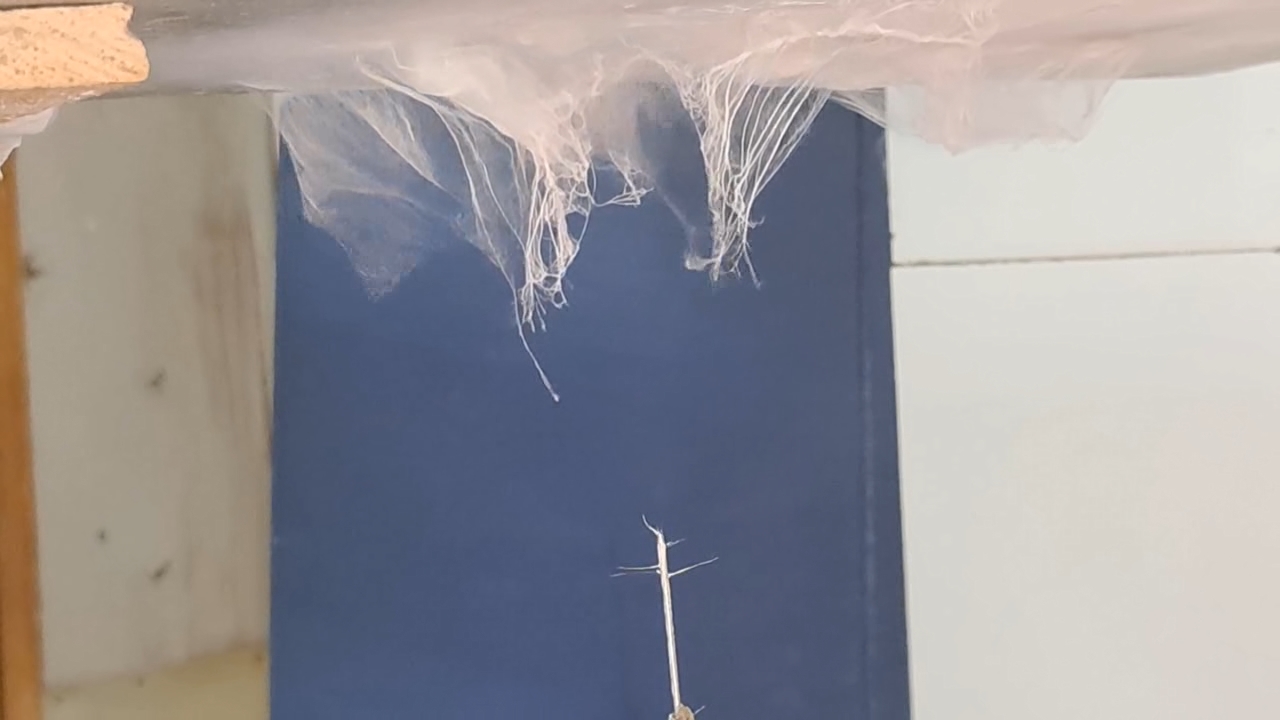

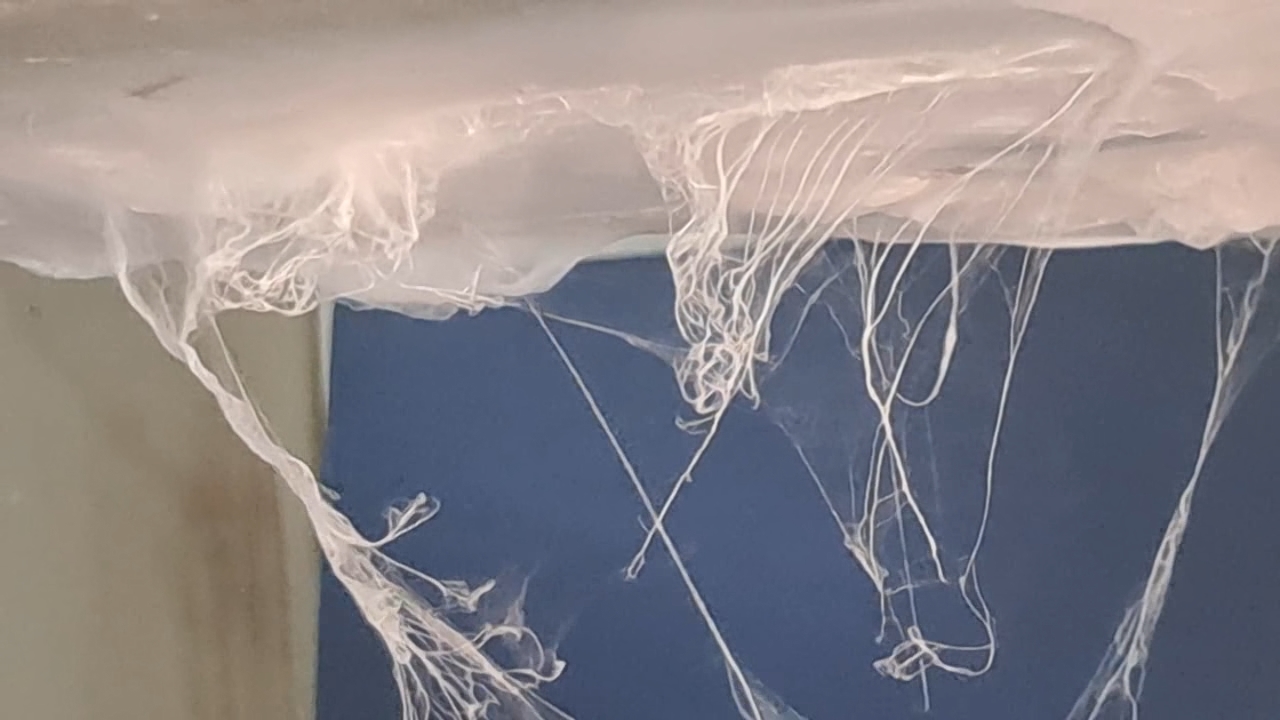

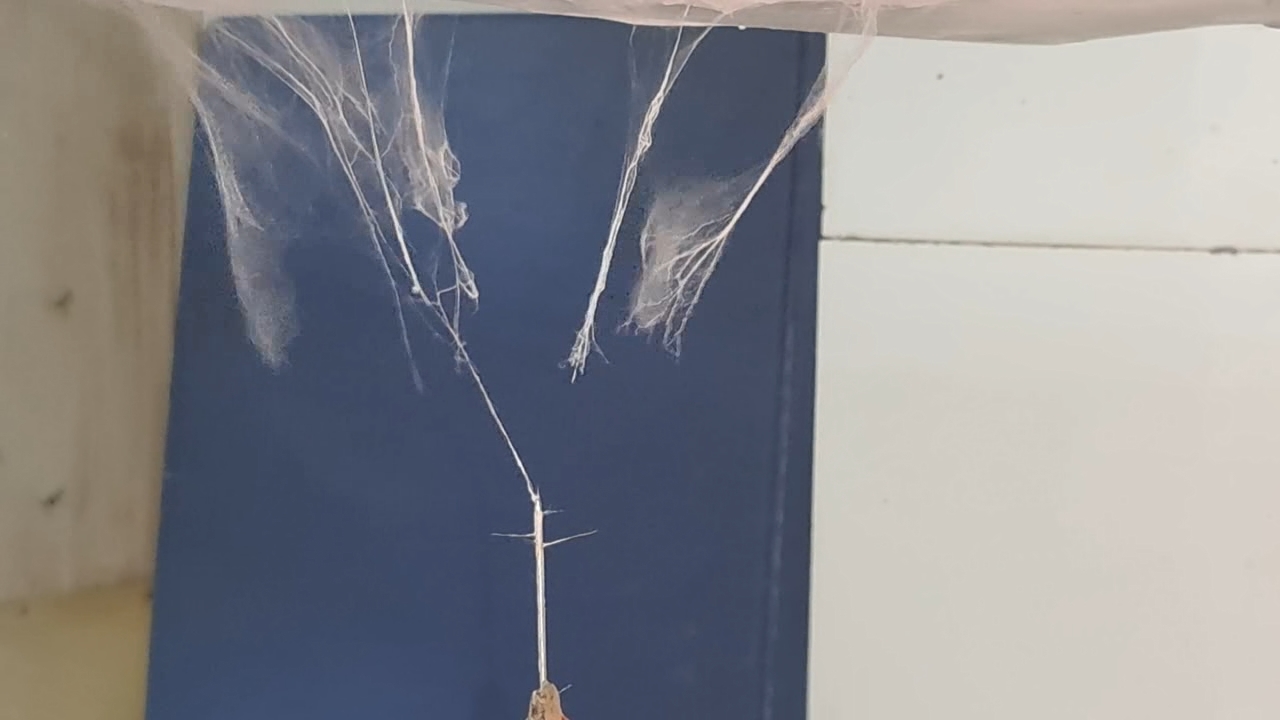

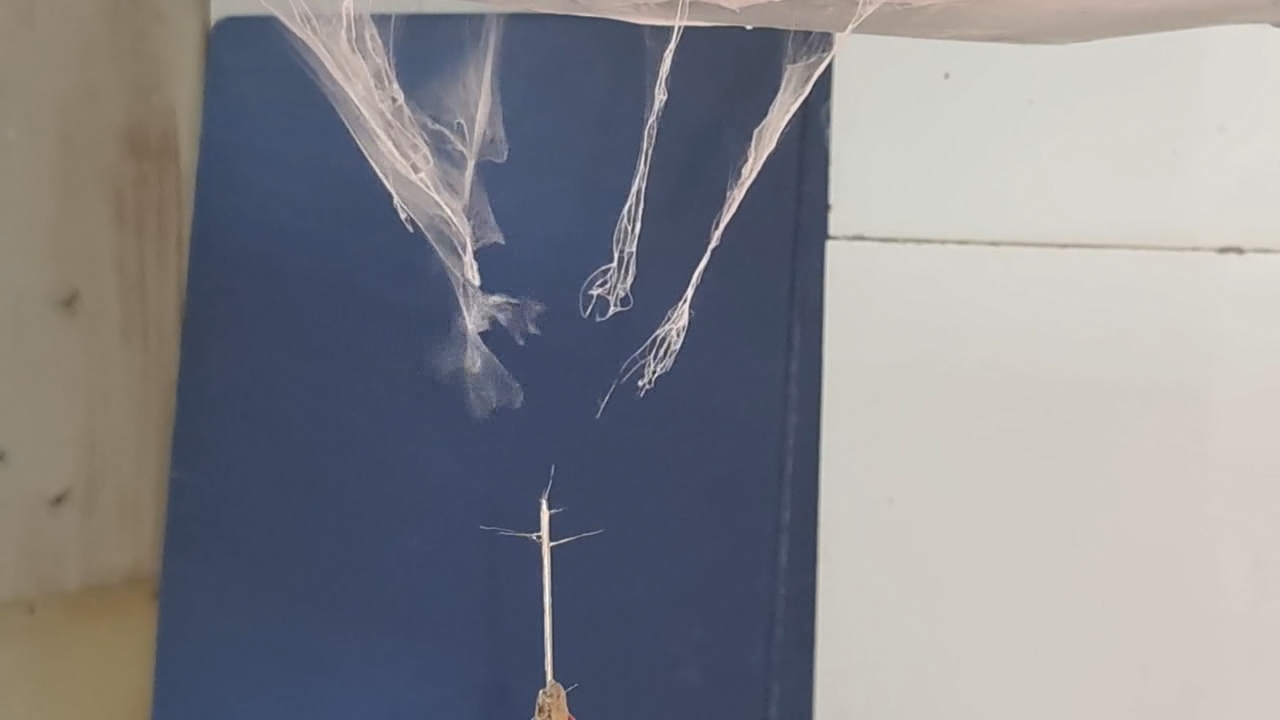

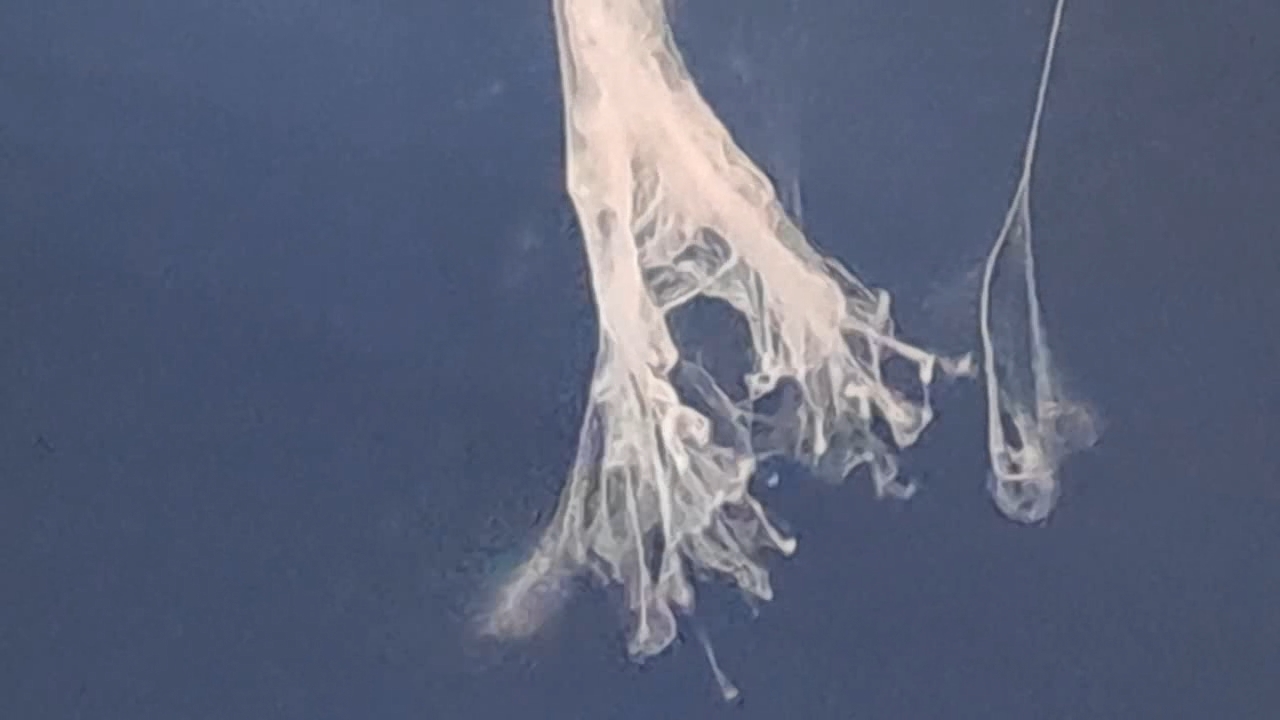

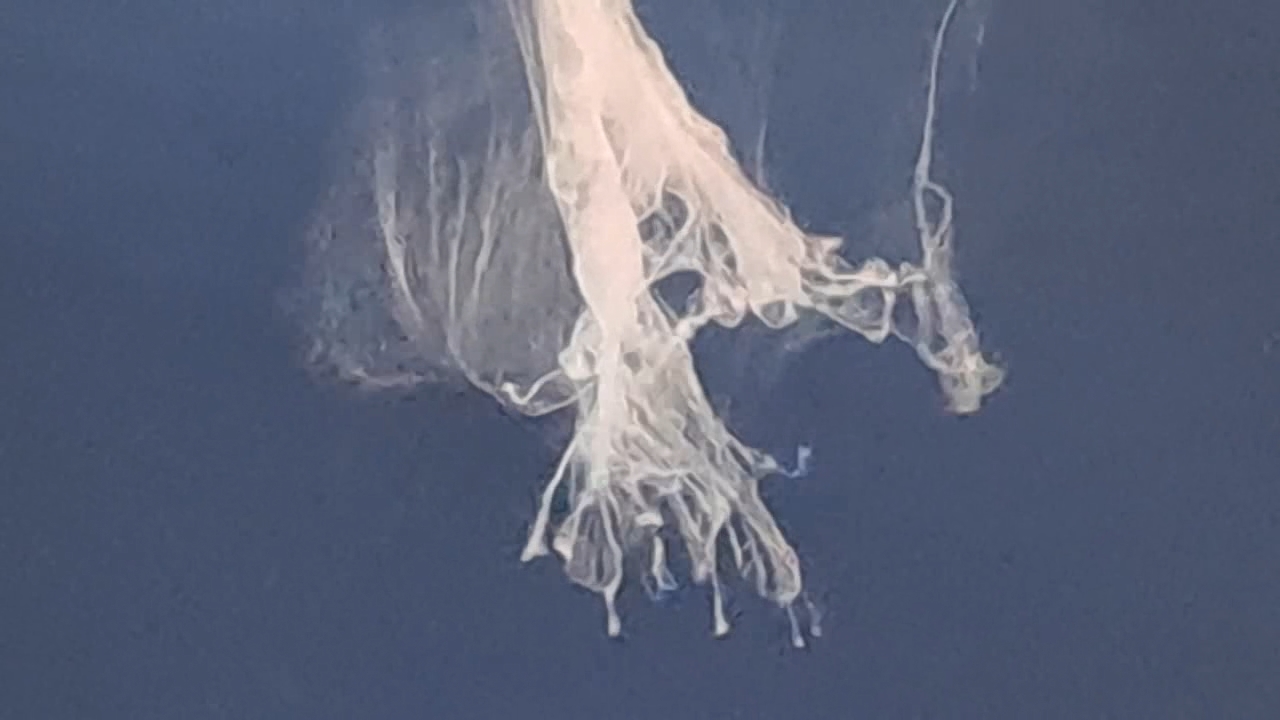

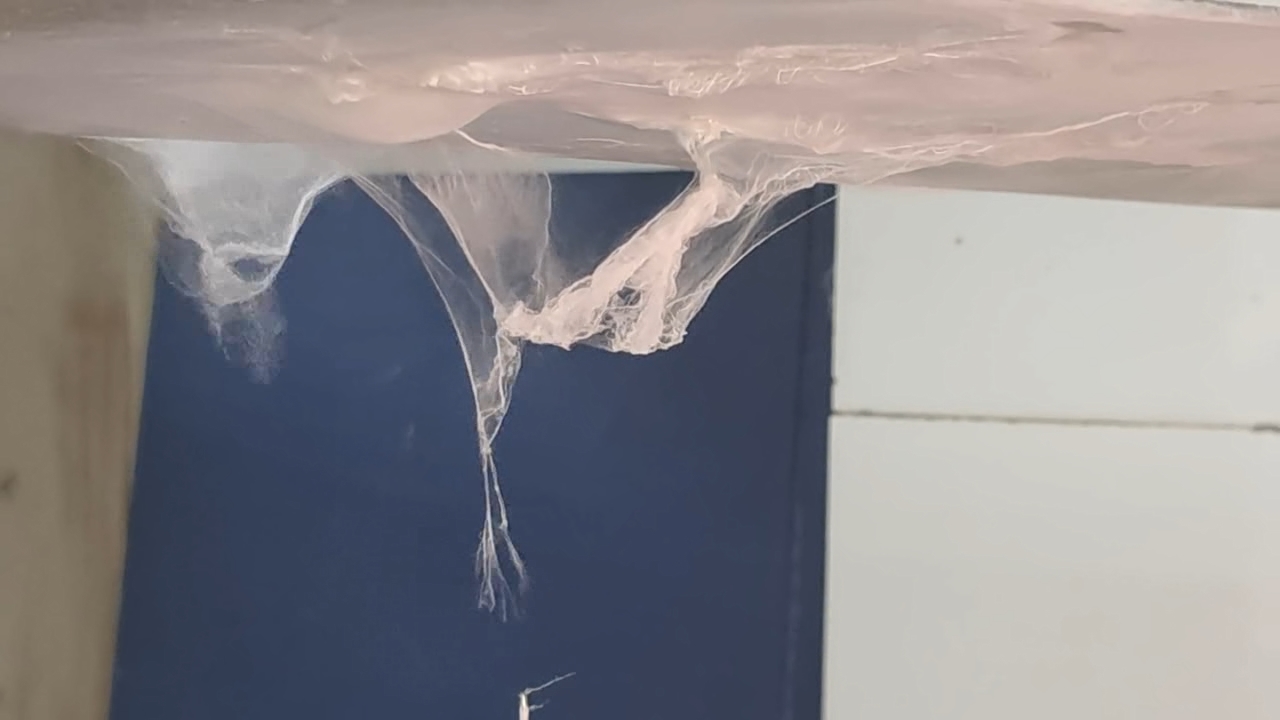

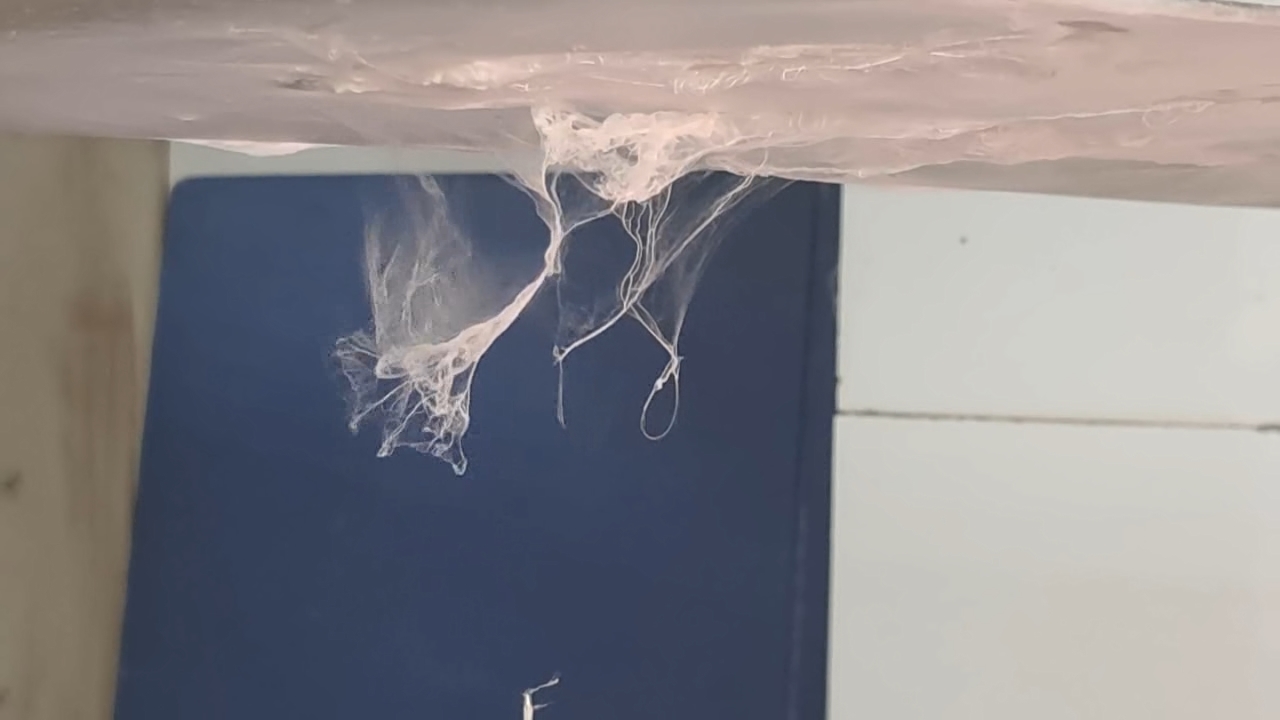

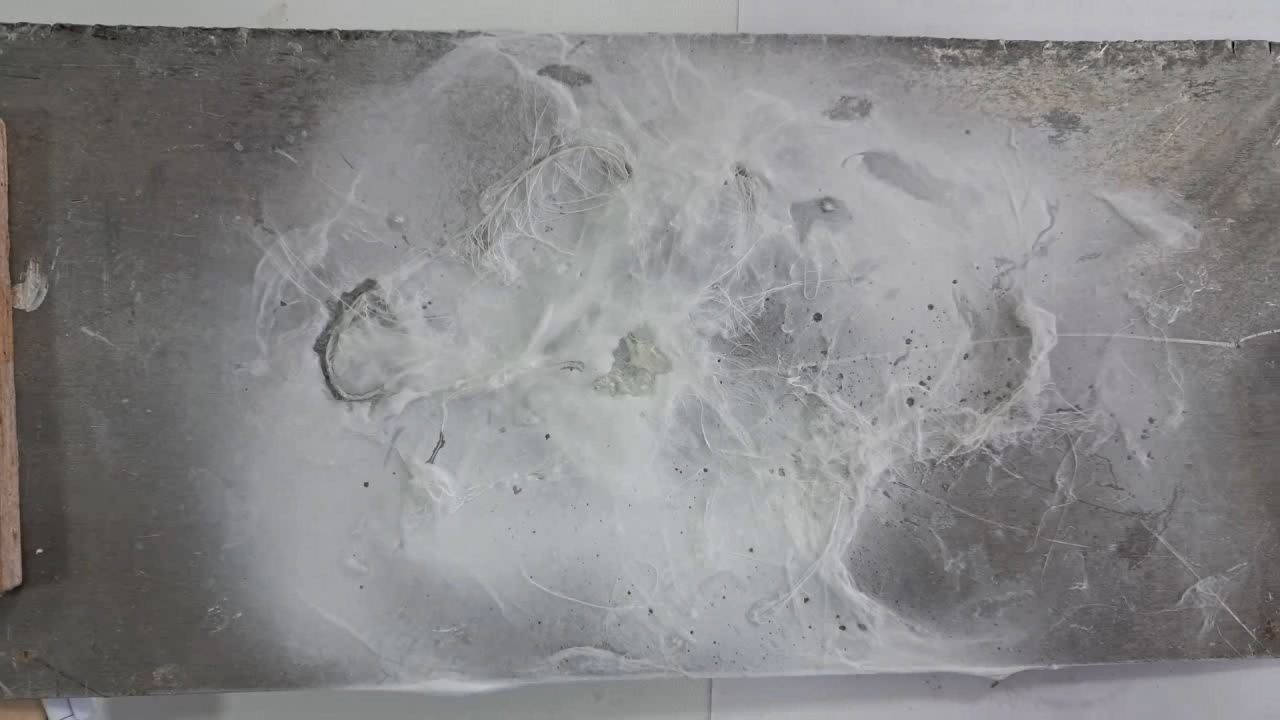

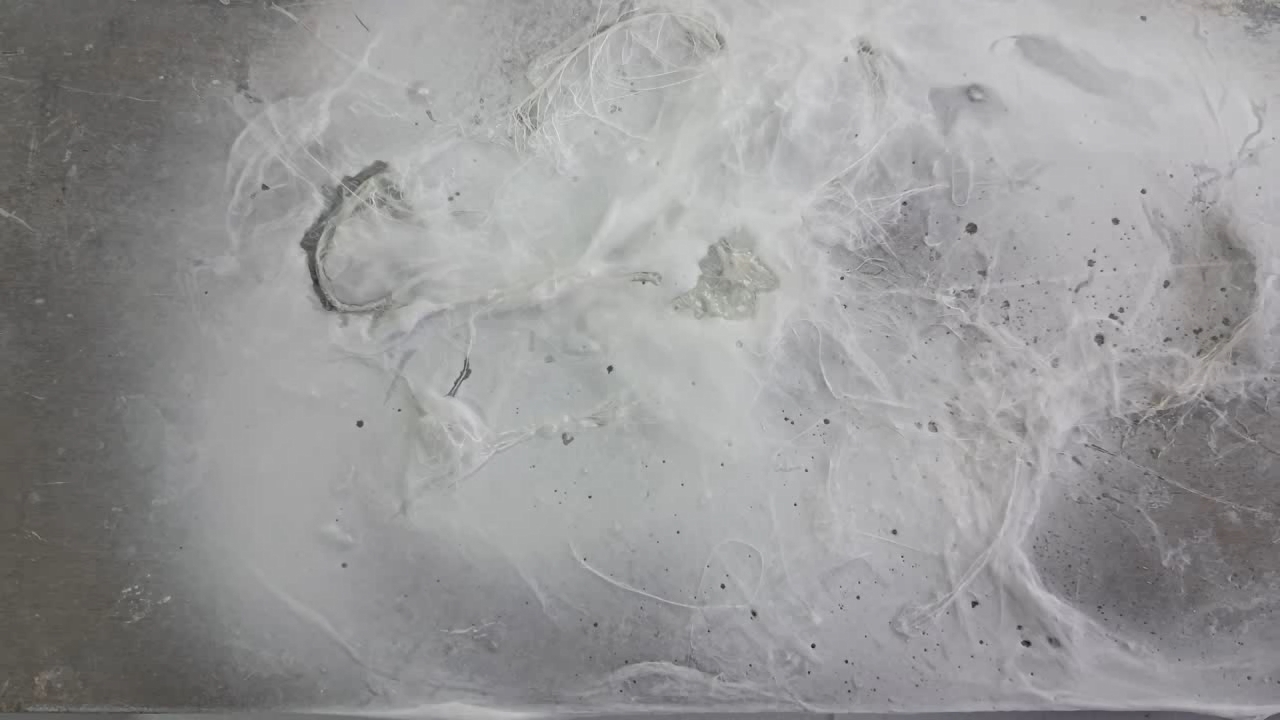

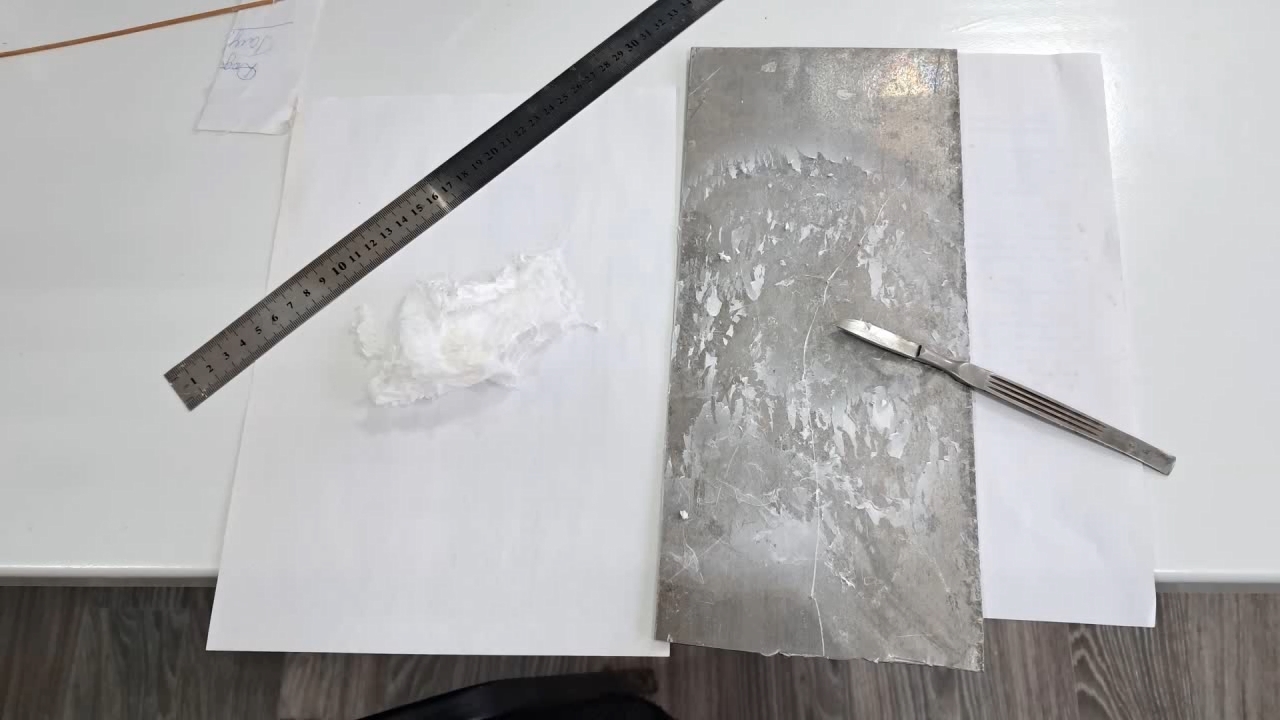

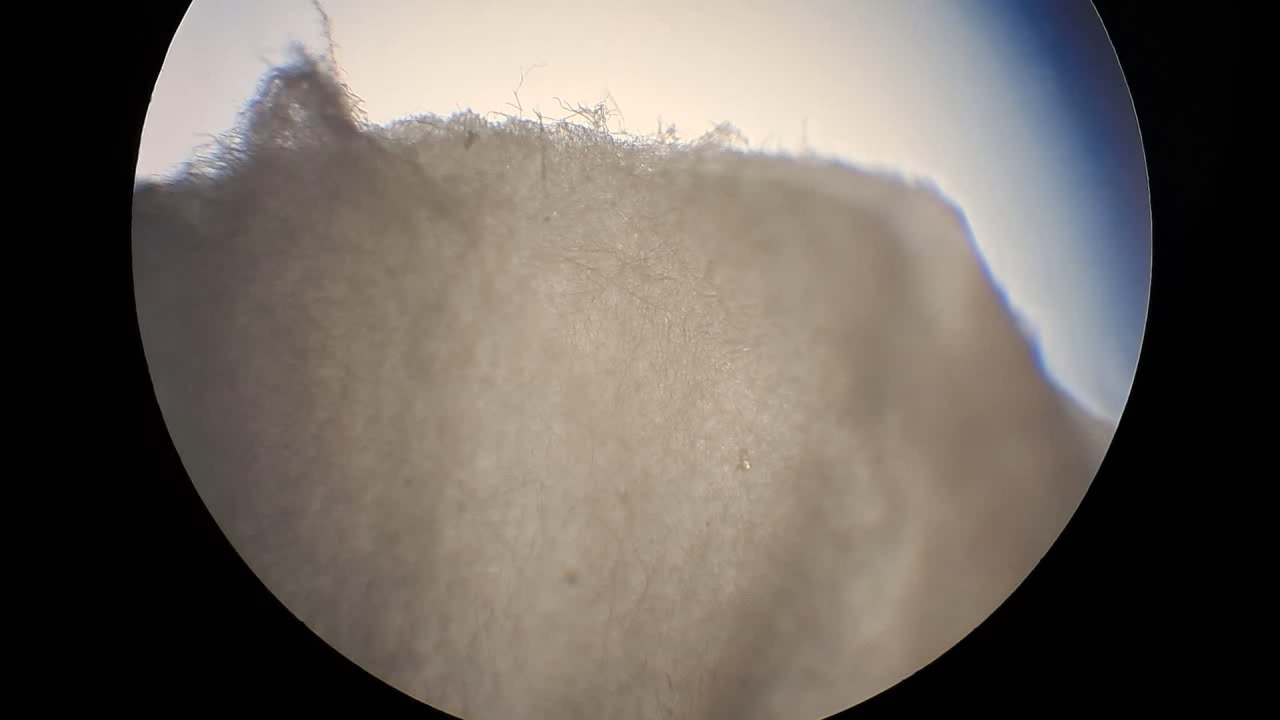

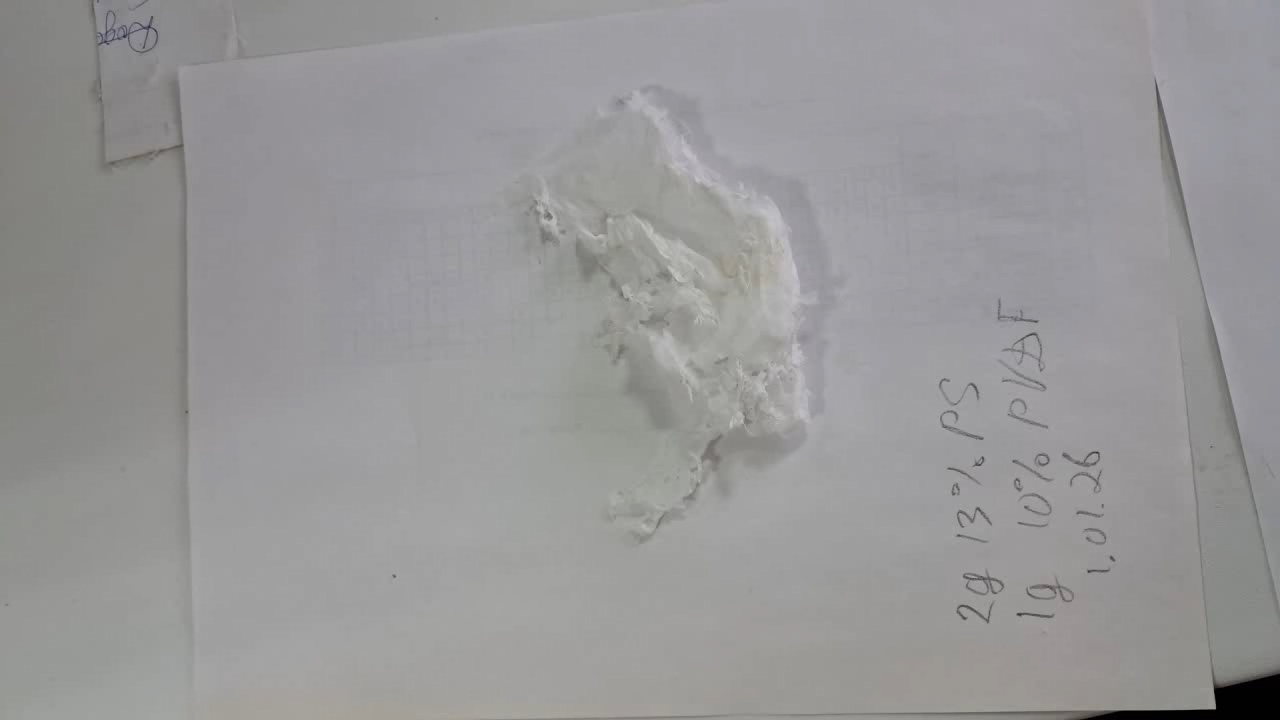

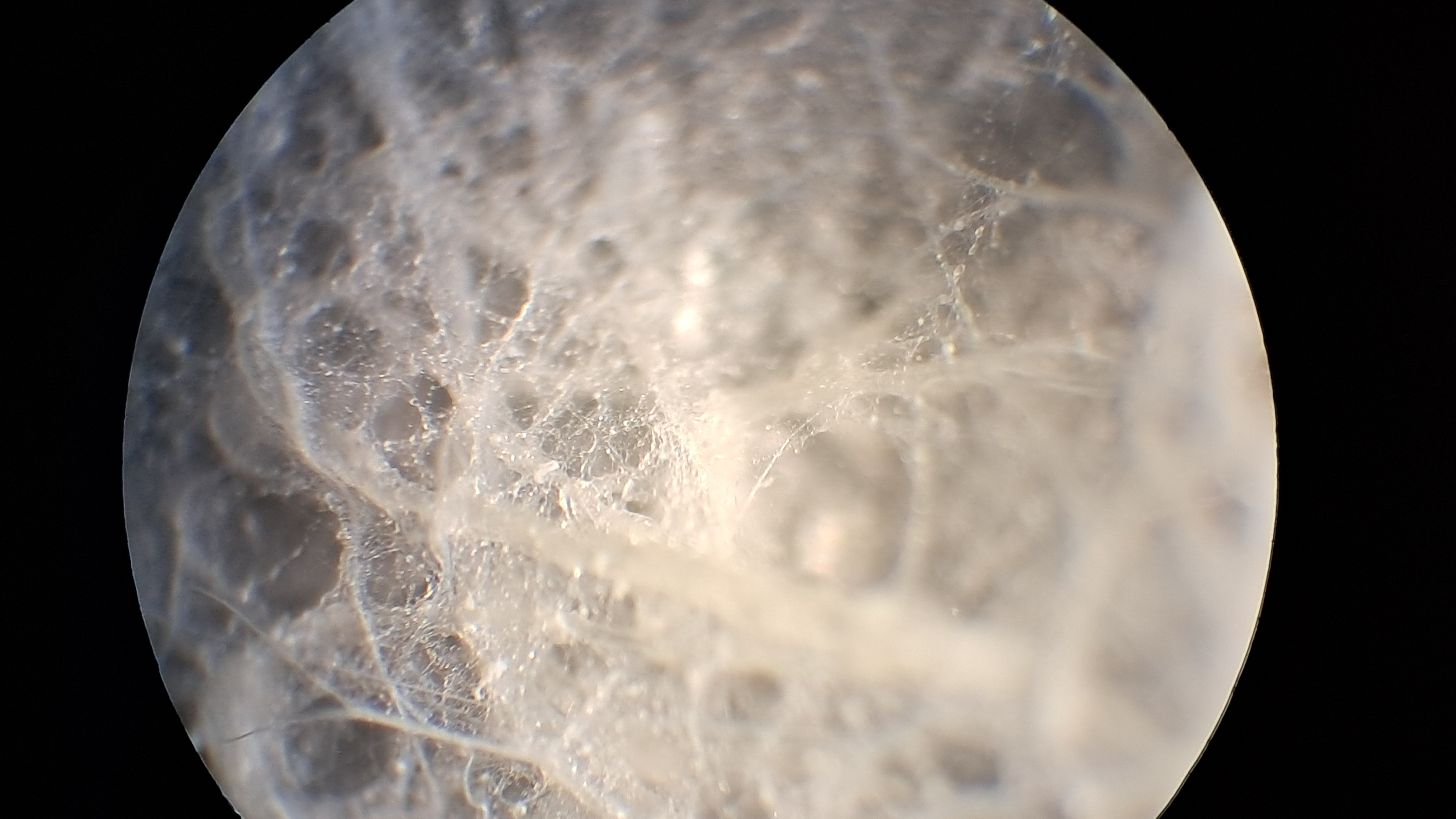

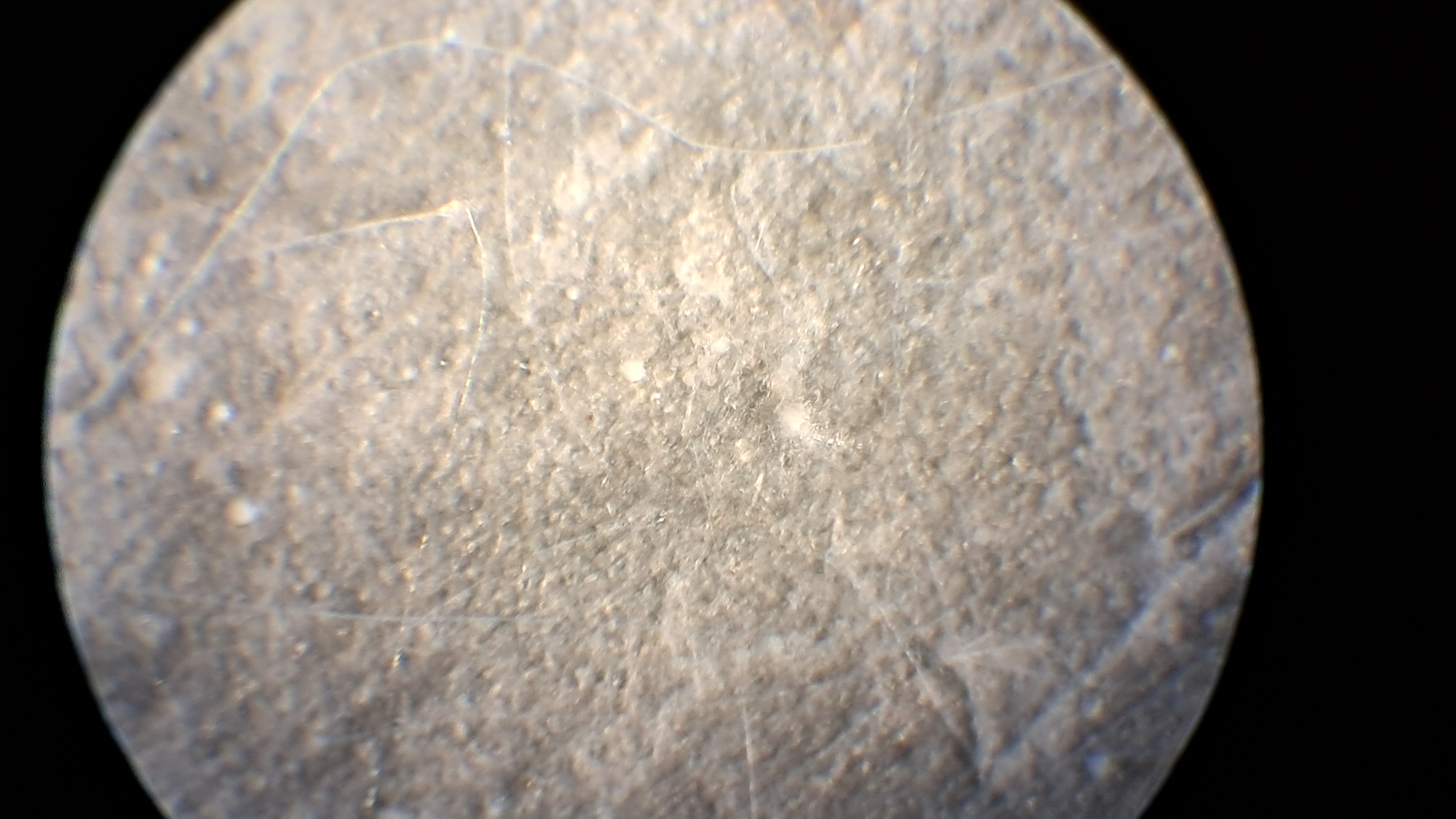

Электроспиннинг: раствор полистирола и поливинилиденфторида в диметилформамиде - Часть 26 I came up with the idea of mixing solutions of polystyrene and PVDF in DMF. In the first experiment, polystyrene would be present in excess. If fibers formed during electrospinning of this solution, the proportion of PVDF in the mixture could then be increased from experiment to experiment, until fiber formation ceased. The next day, I came to the laboratory and weighed out 2.025 g of a 13.6% polystyrene solution in DMF and 1.165 g of a 10.1% PVDF solution in DMF. I mixed the two solutions, and the liquid became cloudy. The resulting mixture contained 30% PVDF and 70% polystyrene by weight. My chemist colleague insisted that polymer solutions should be left to stand for 24 hours after preparation (or mixing) in order to reach equilibrium. Otherwise, experimental results might be unsatisfactory or irreproducible. At first, I did not believe him, thinking that he was simply inventing another excuse to delay the work. Later, I learned that diffusion in viscous solutions containing long polymer macromolecules can be very slow. Even vigorous stirring does not always help. Be that as it may, this time I did not wait. I immediately drew the cloudy liquid into a syringe and began electrospinning. I hoped that fibers would form, although the addition of PVDF to polystyrene could have interfered with the process - for example, by promoting aerosol formation. My fears were unfounded. Visually, the experiment resembled the previous one with the pure polystyrene solution. A barely noticeable cone emanated from the needle, and the same "cotton-wool formation in the air" that had been observed the day before appeared again. Adding 30% PVDF to the polystyrene did not prevent fiber formation. The coating on the collector was uneven. This was most likely due to my use of the highest flow rate allowed by the syringe pump. Fibers were clearly visible under the microscope, and their diameter was significantly smaller than in the previous experiment. While reviewing the edited video, I noticed a corona discharge emanating from the tip of the needle and from the fibers as they formed. The discharge was occasionally visible, despite the bright lighting. I immediately proceeded to the next experiment. I mixed 1.020 g of a 13.6% polystyrene solution in DMF with 2.120 g of a 10.1% PVDF solution in DMF. The resulting mixture contained 60.7% PVDF and 39.3% polystyrene by weight. Despite the fact that the PVDF content exceeded that of polystyrene, electrospinning produced a material similar to that obtained previously. The resulting coating was white, uneven, and composed of microscopic fibers. |

Electrospinning: Solutions of Polystyrene (70% by wt.) and Polyvinylidene Difluoride (30%) in Dimethylformamide |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Having noticed a mistake in the text, allocate it and press Ctrl-Enter

Electrospinning: Solutions of Polystyrene and Polyvinylidene Difluoride in Dimethylformamide - Part 27

Over the next few days, I experimented with pure polystyrene solutions at higher concentrations, which I will discuss later. About a week later, I returned to the co-electrospinning of PVDF with polystyrene. This time, I planned to use a solution containing significantly more PVDF than polystyrene. Since a pure PVDF solution did not form fibers under our experimental conditions, it was logical to assume that, as the polystyrene content decreased, a mixture of the polymer solutions would eventually cease to produce fibrous material during electrospinning.

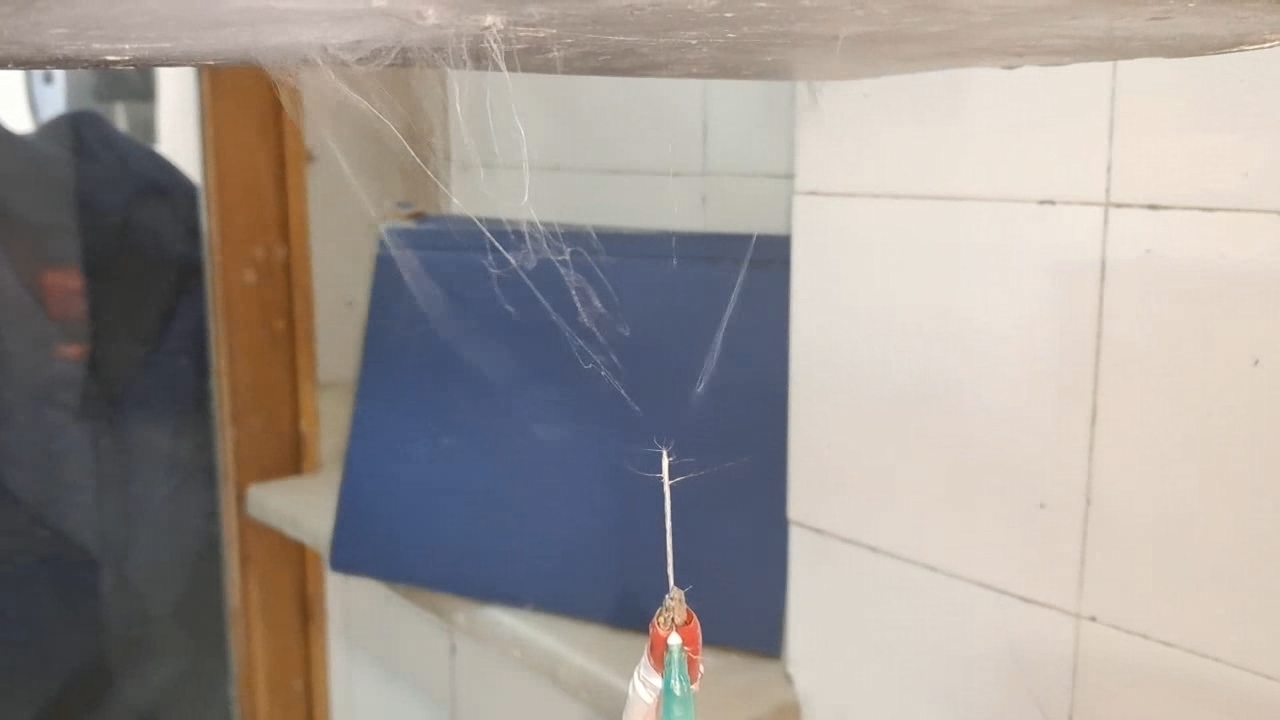

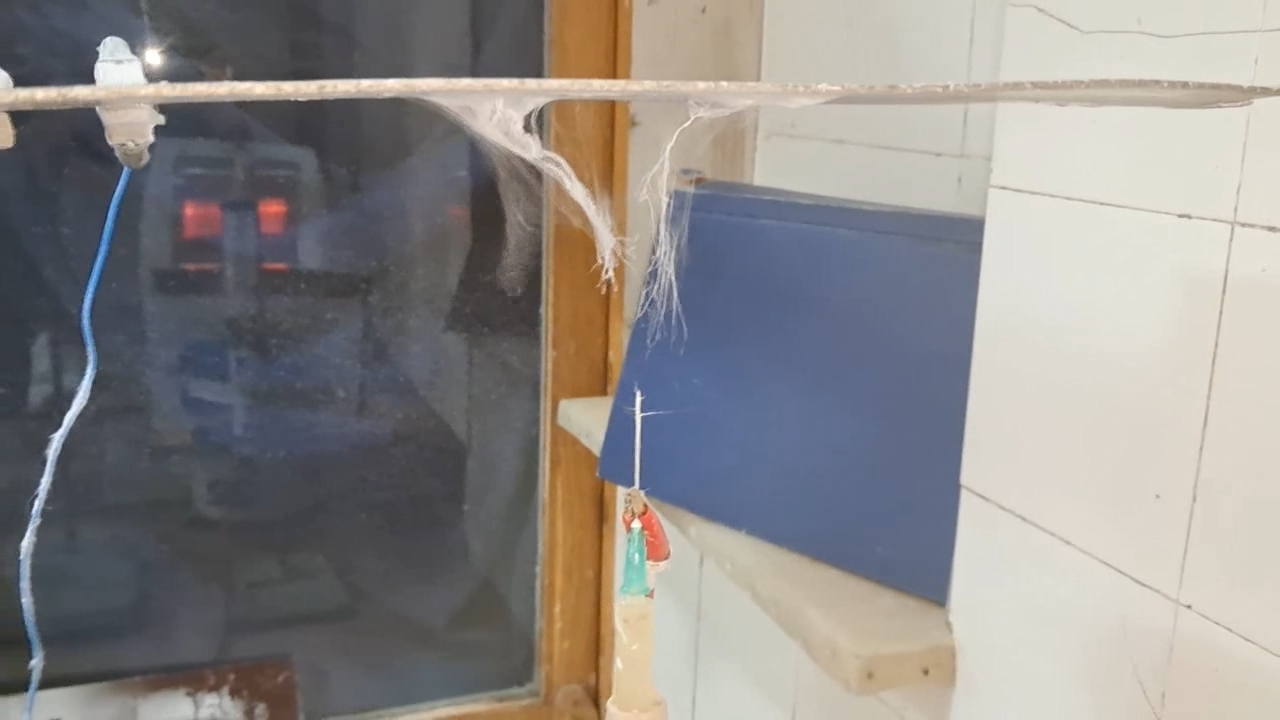

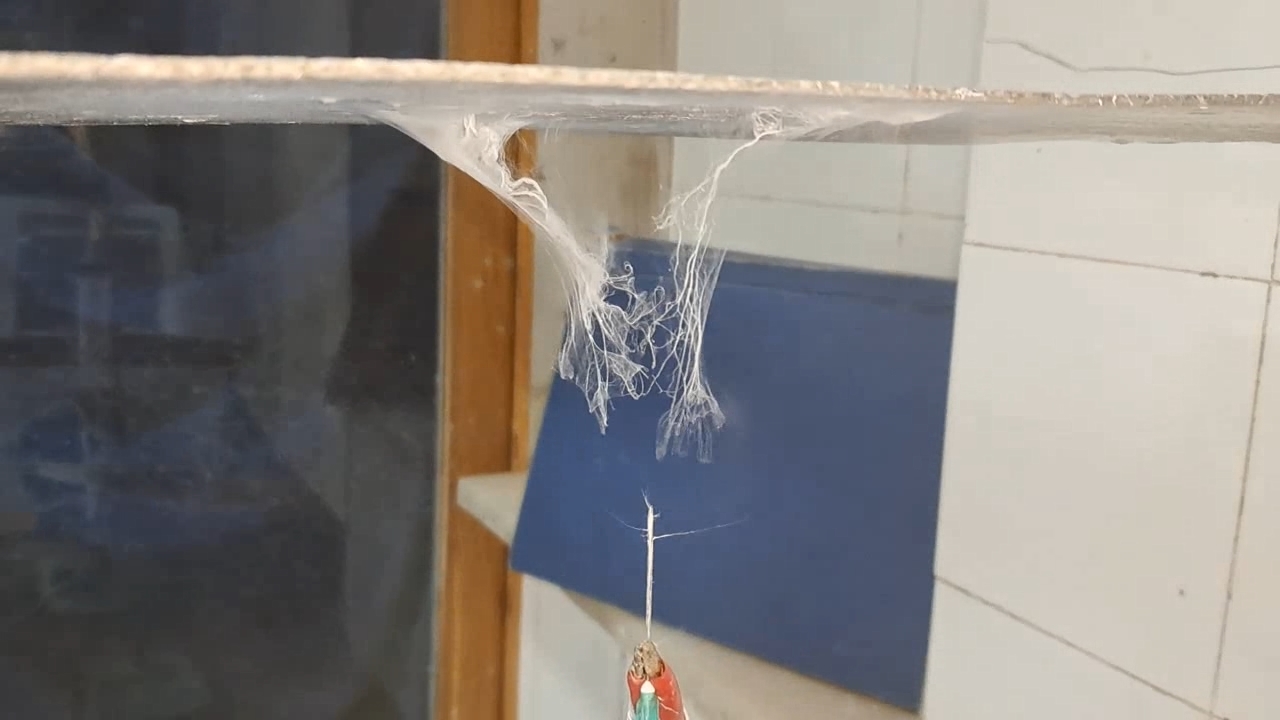

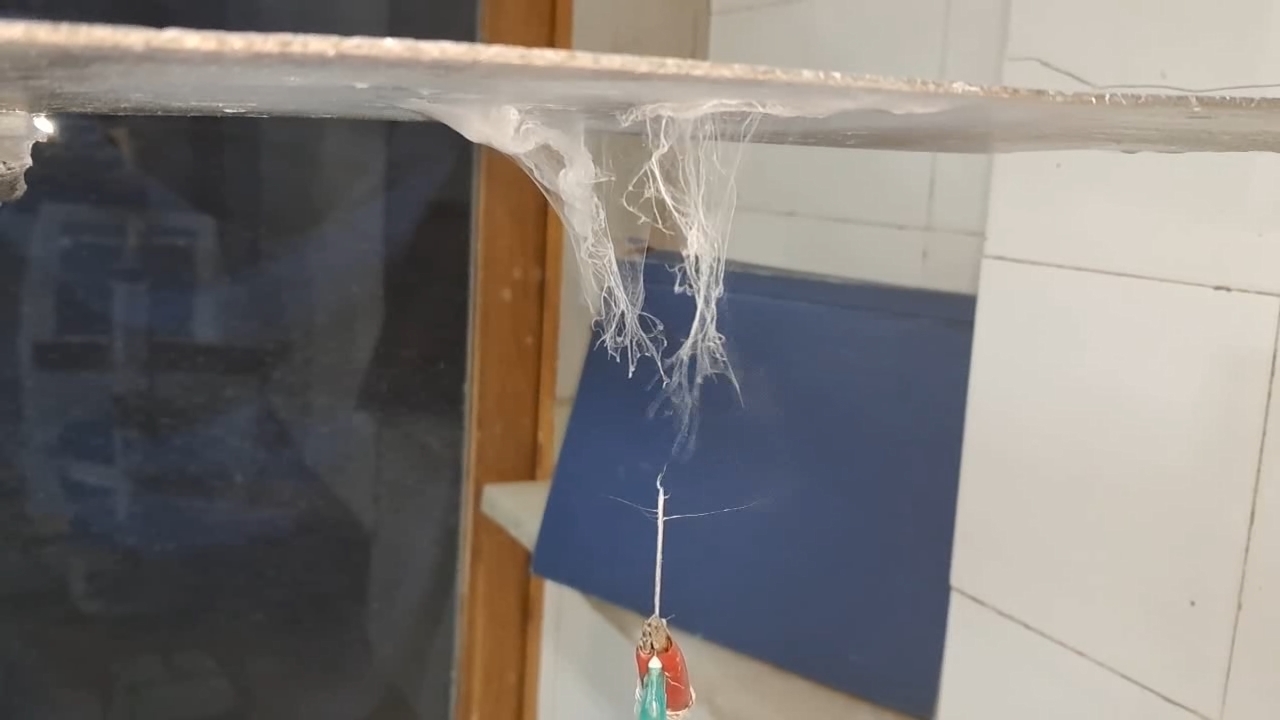

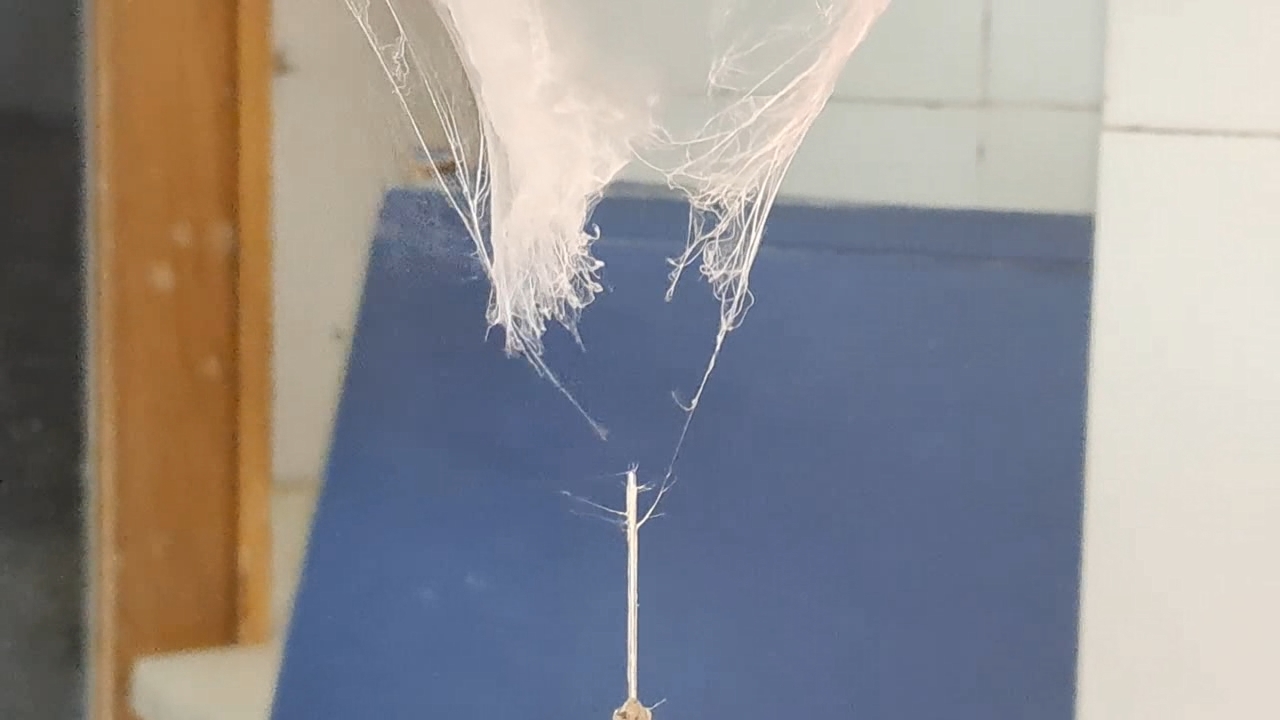

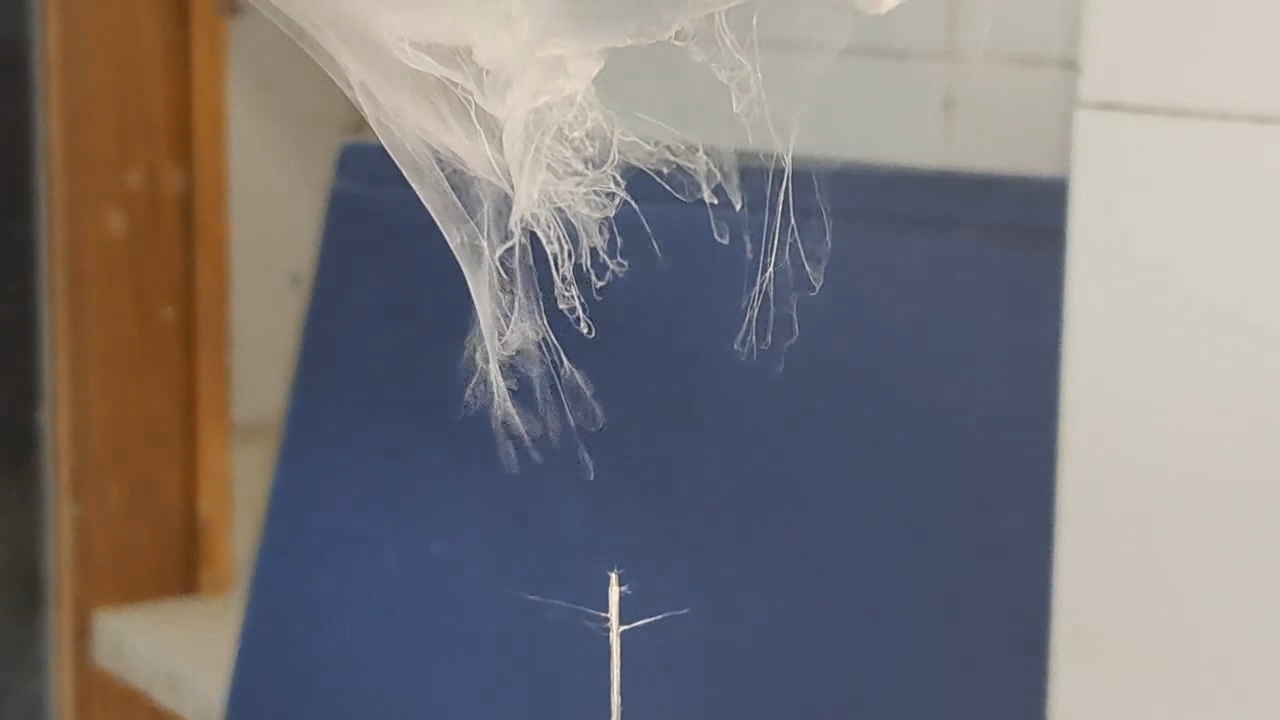

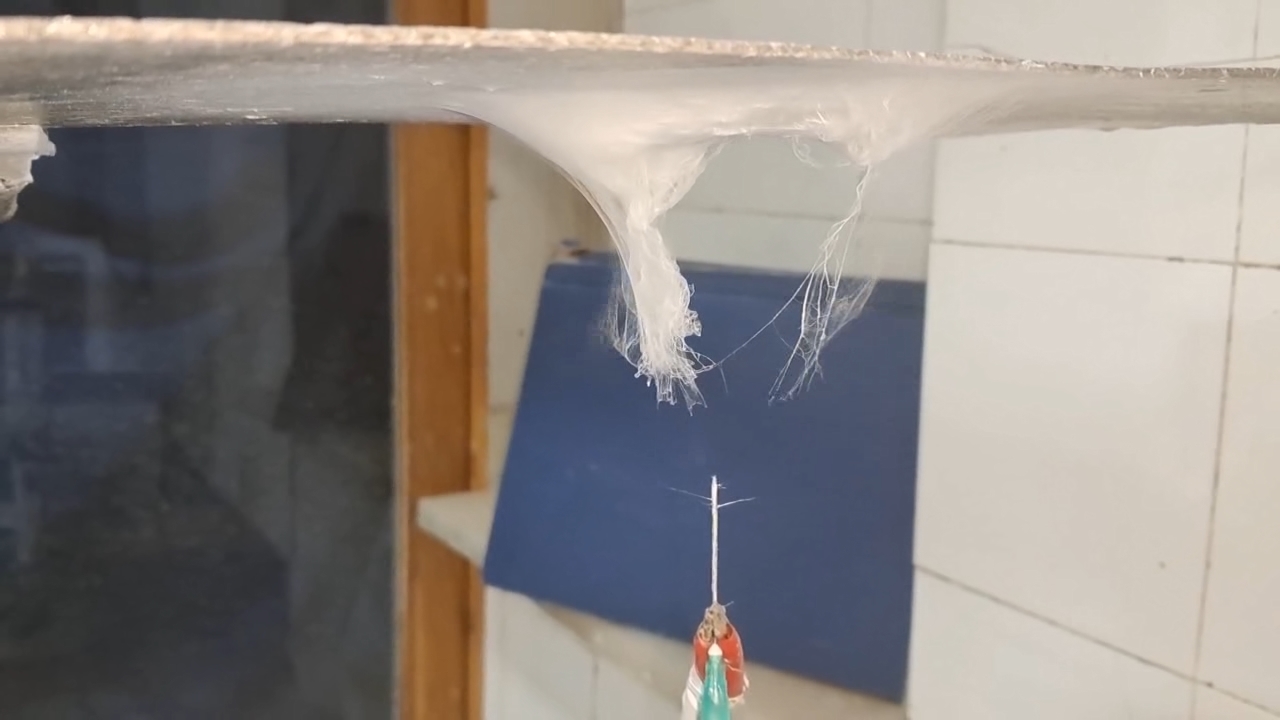

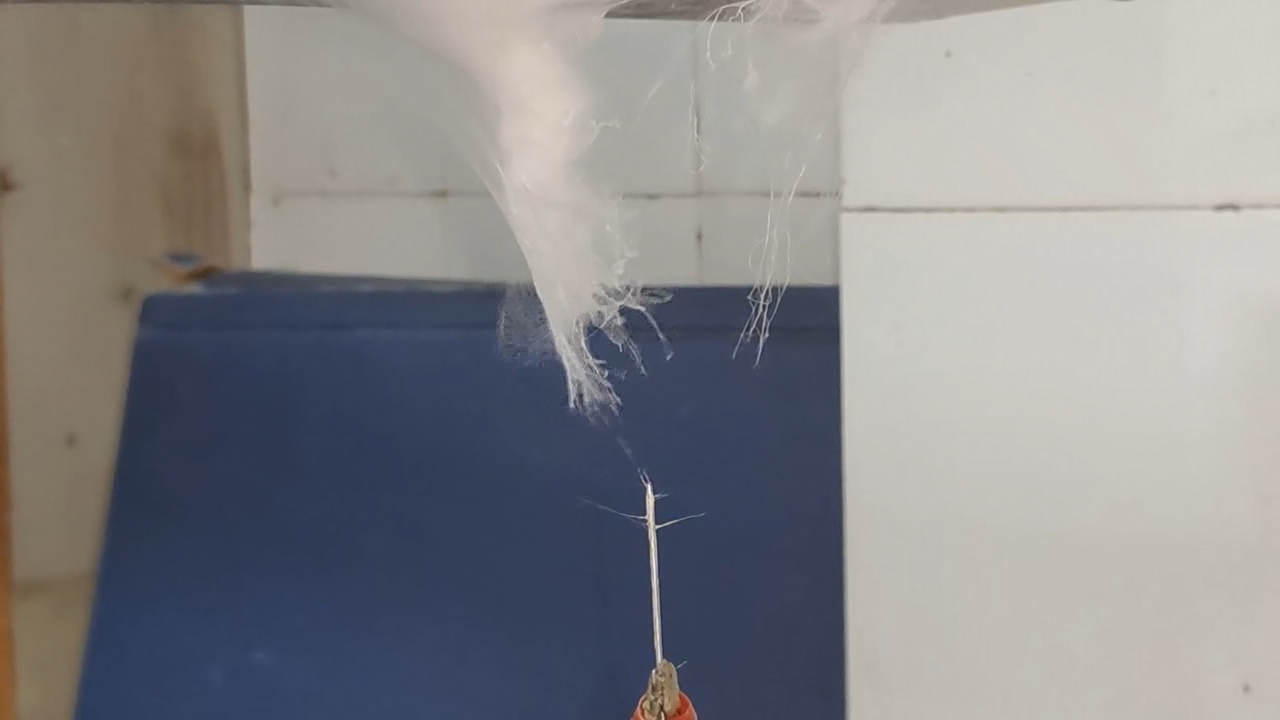

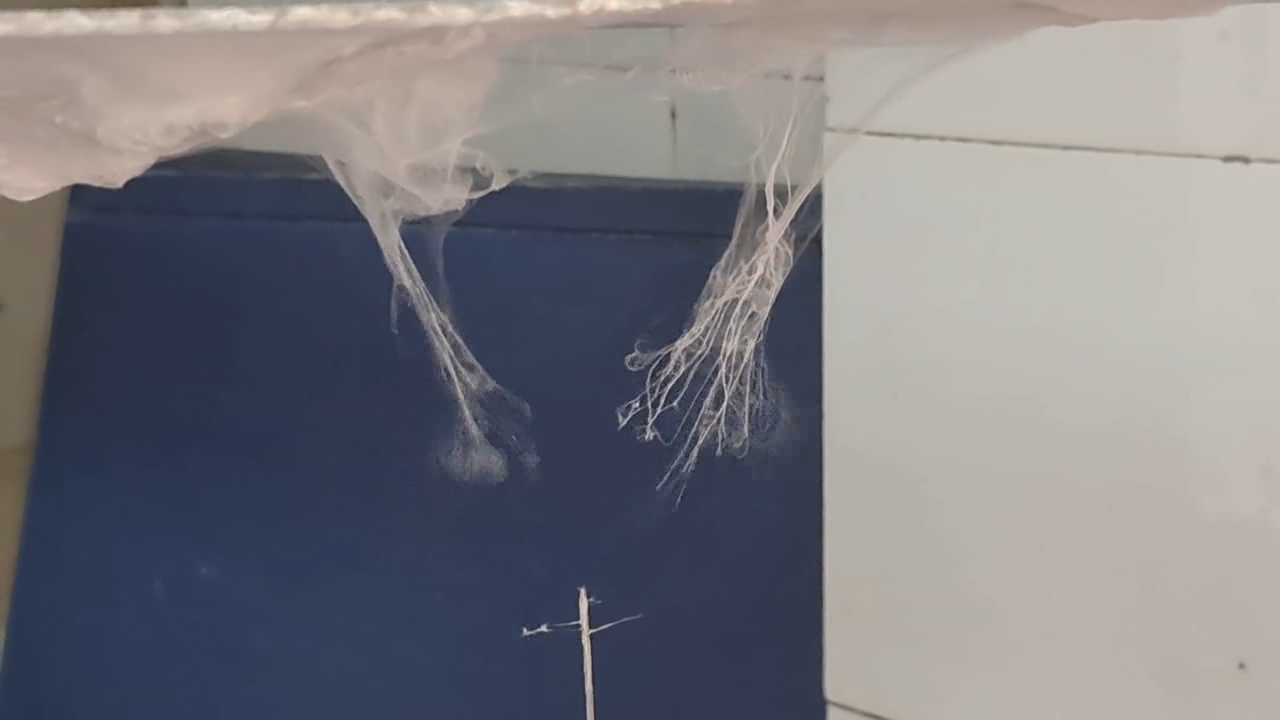

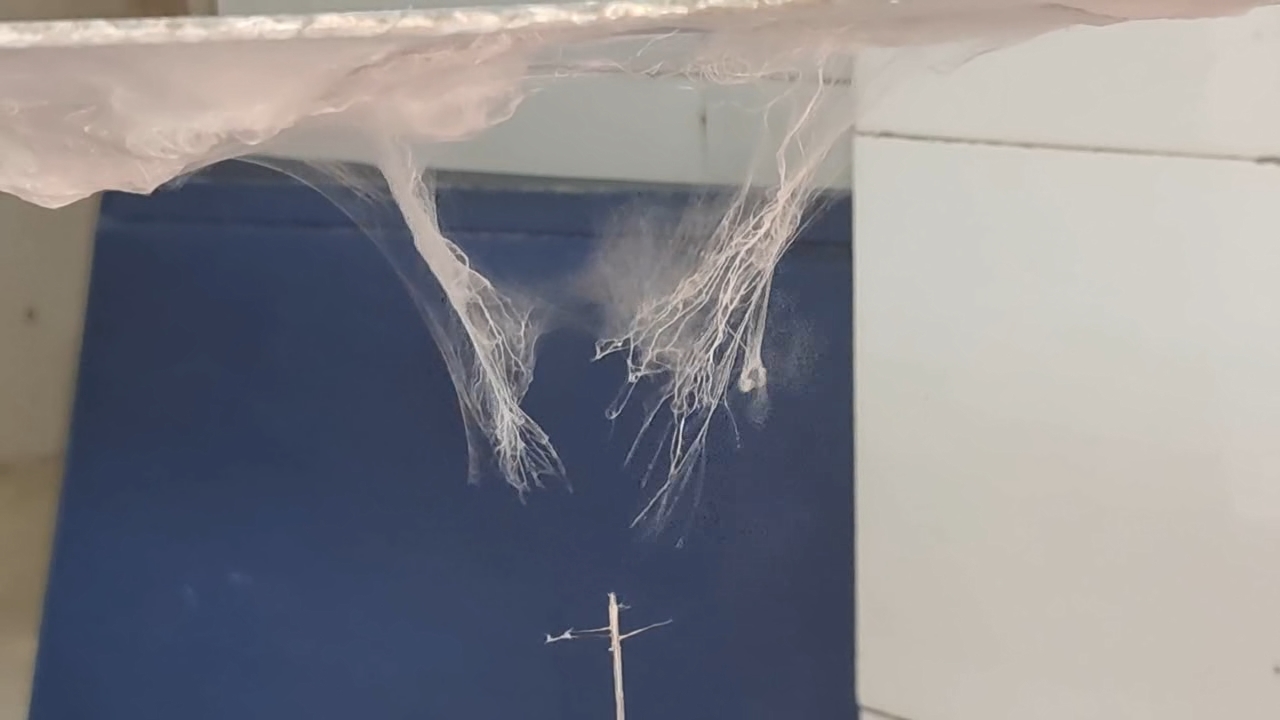

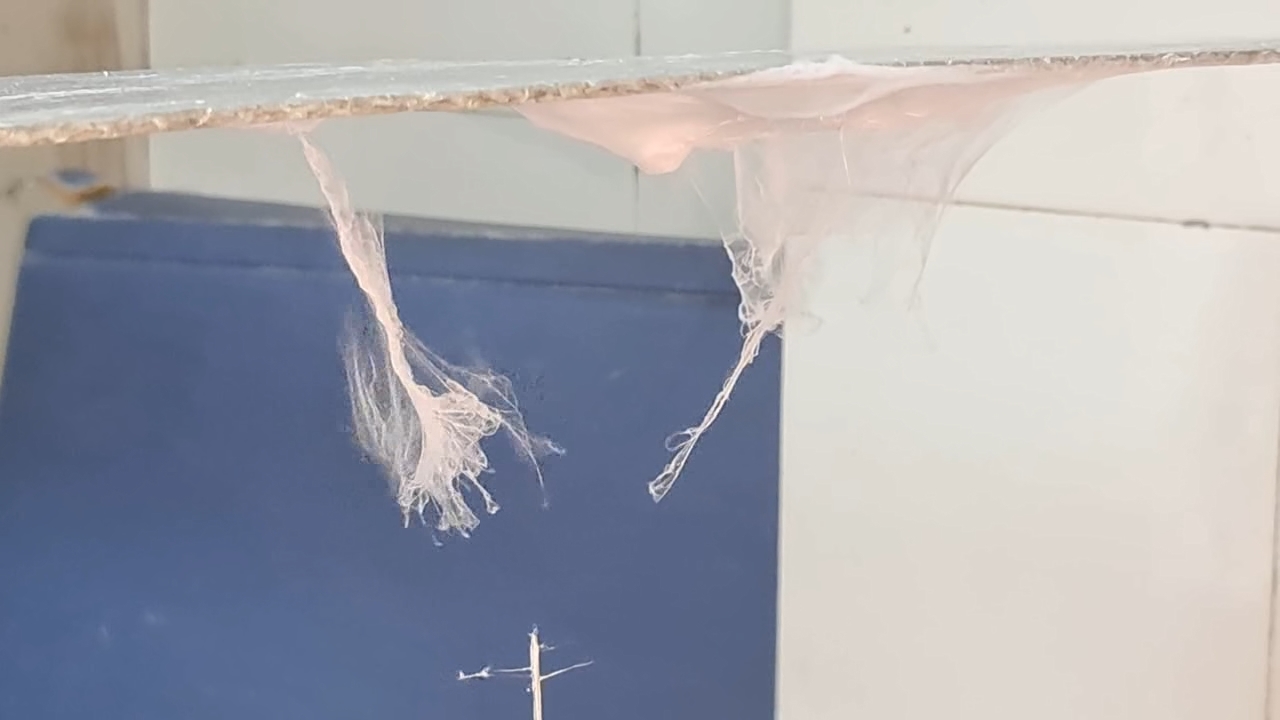

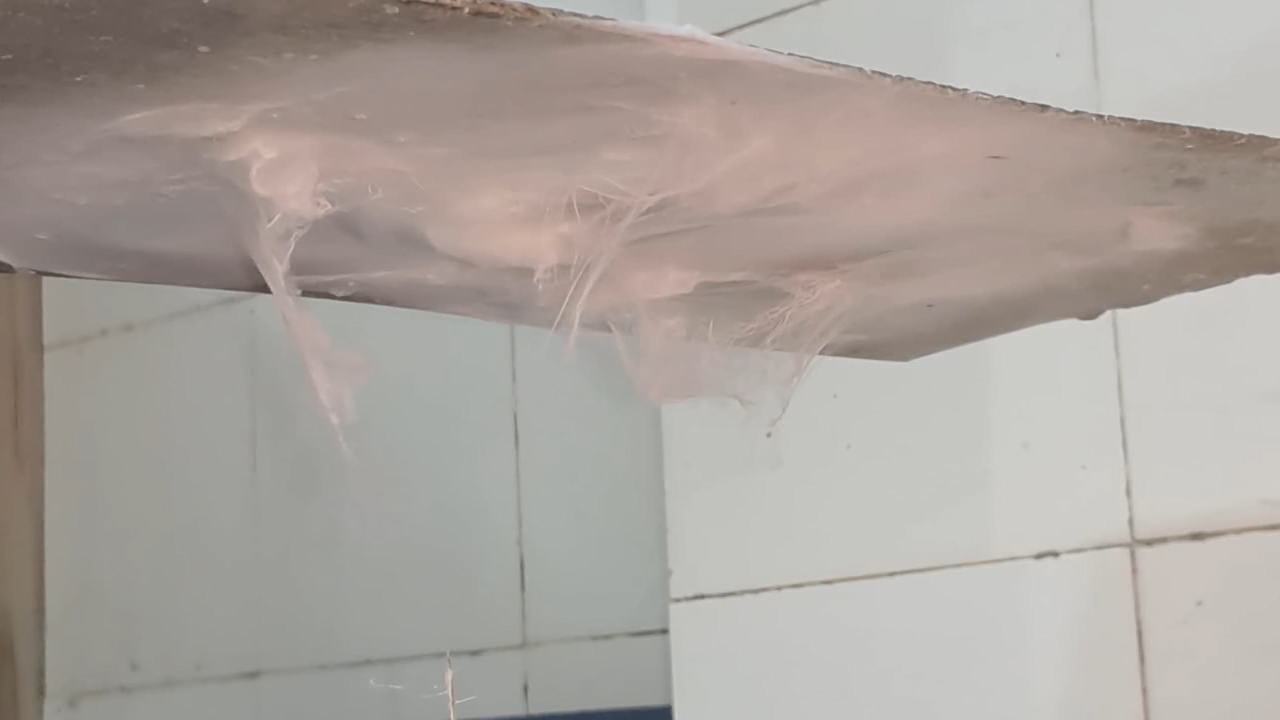

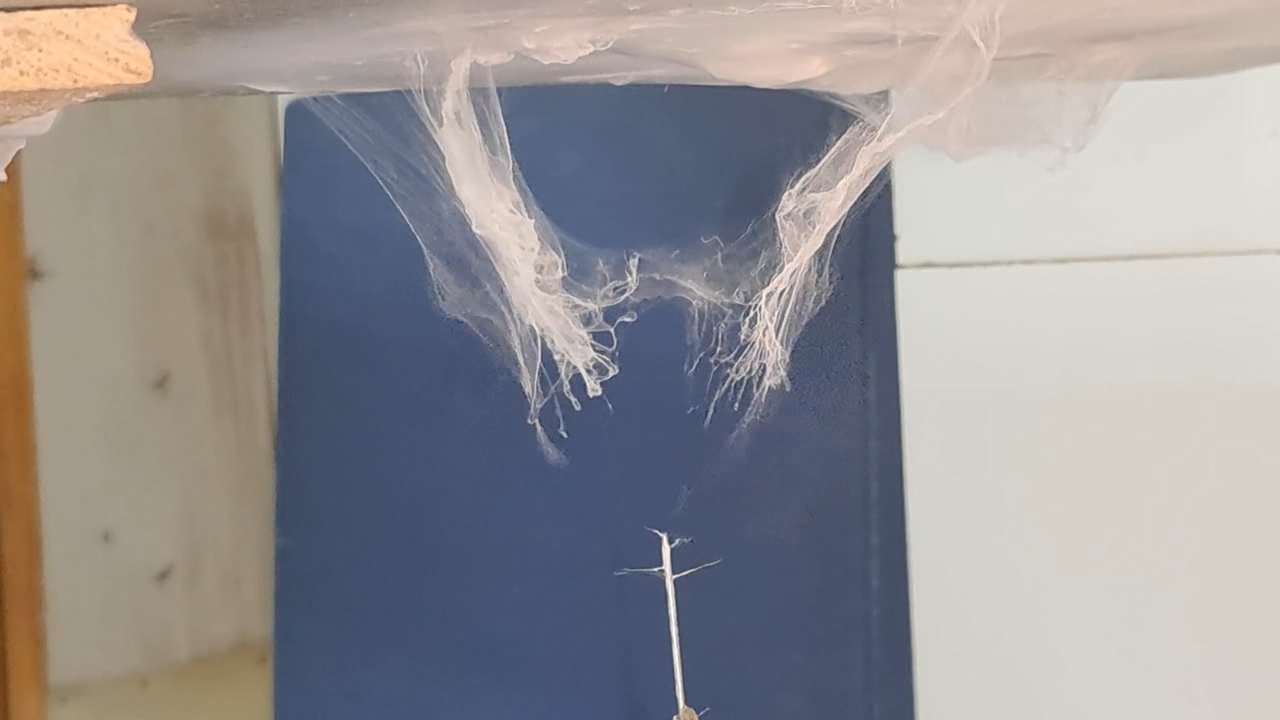

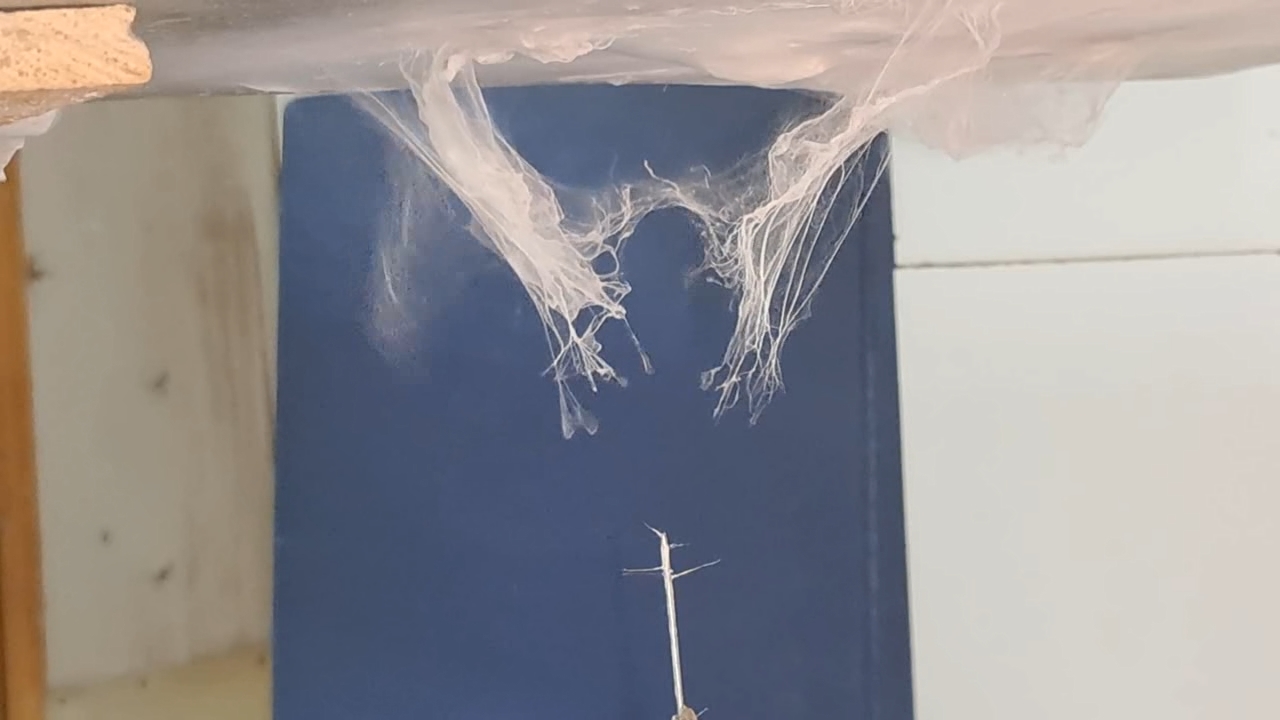

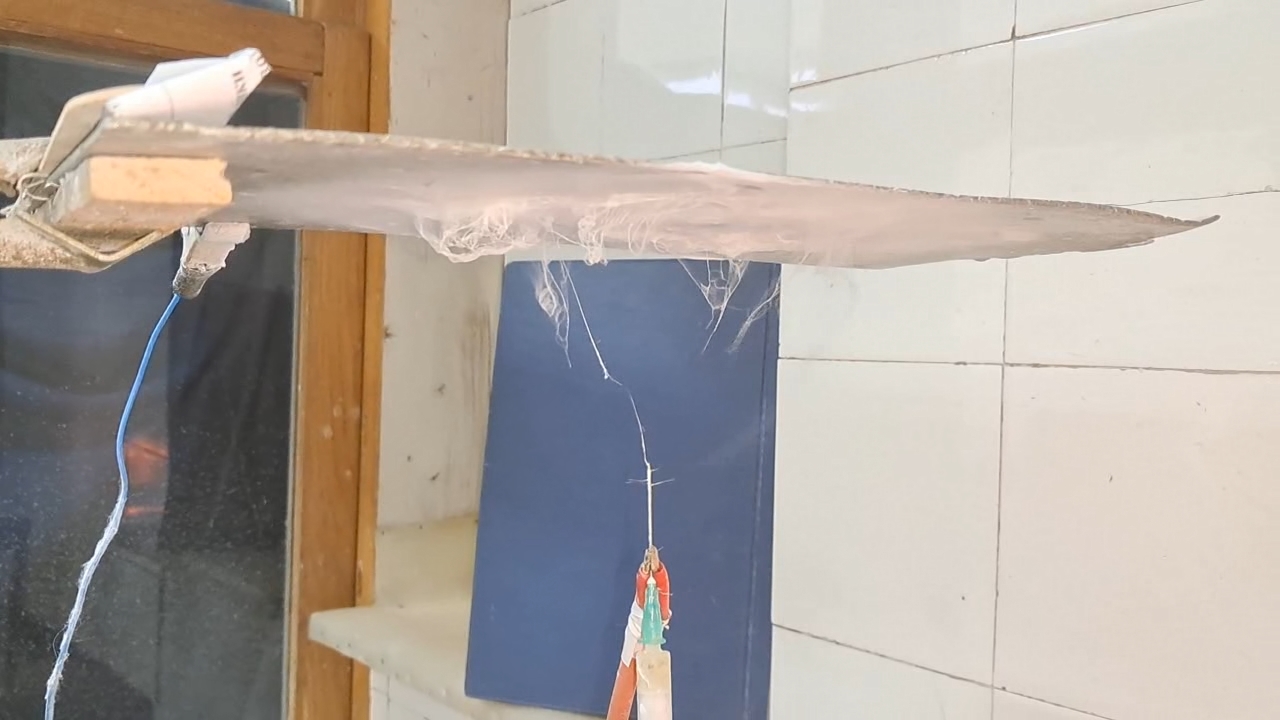

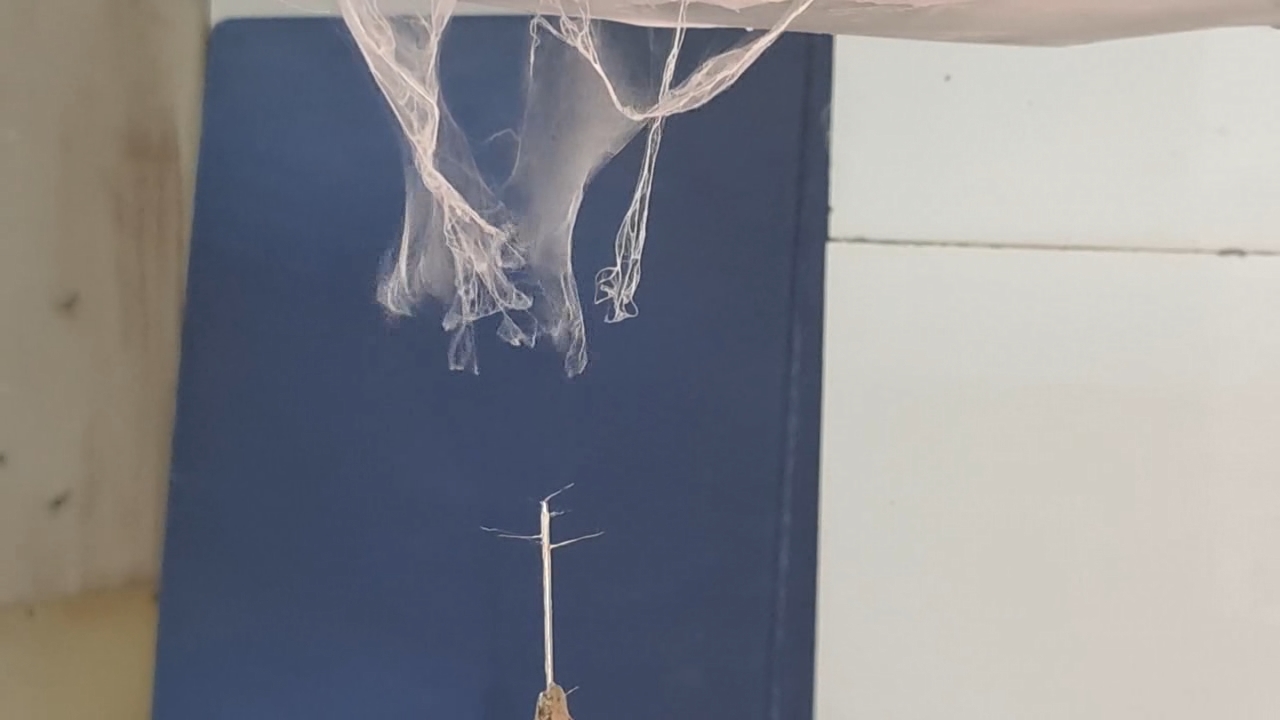

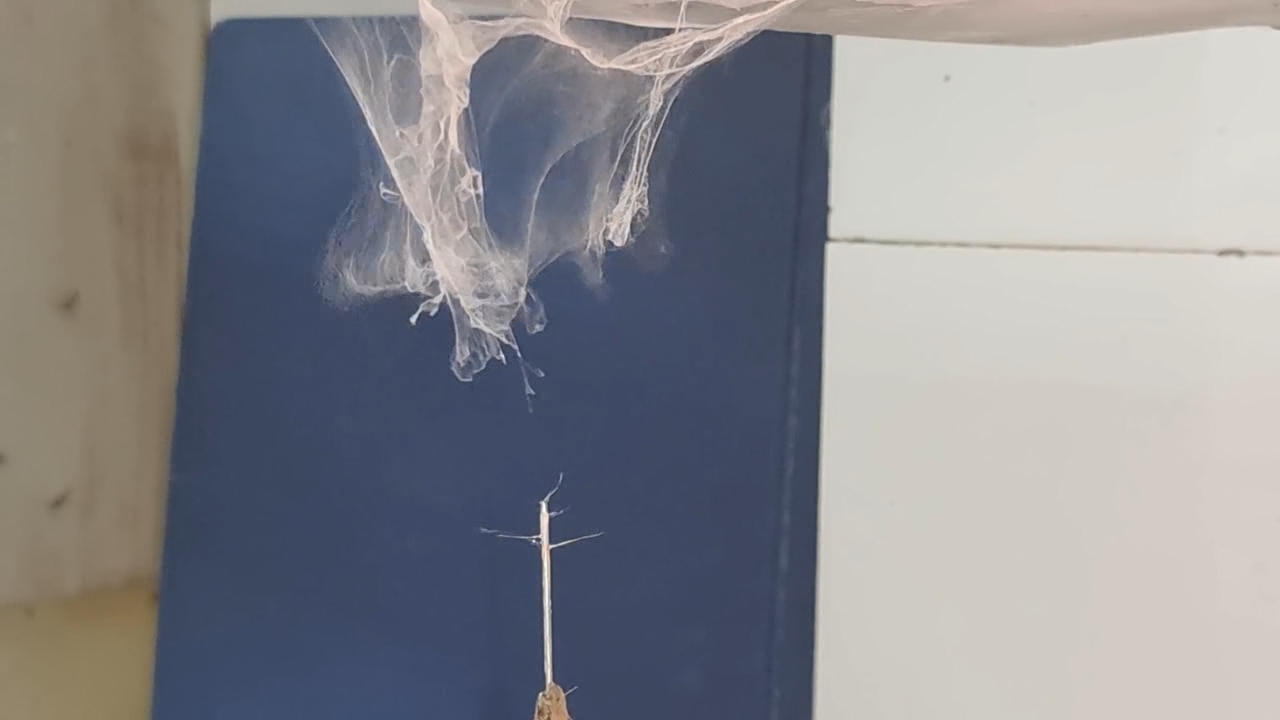

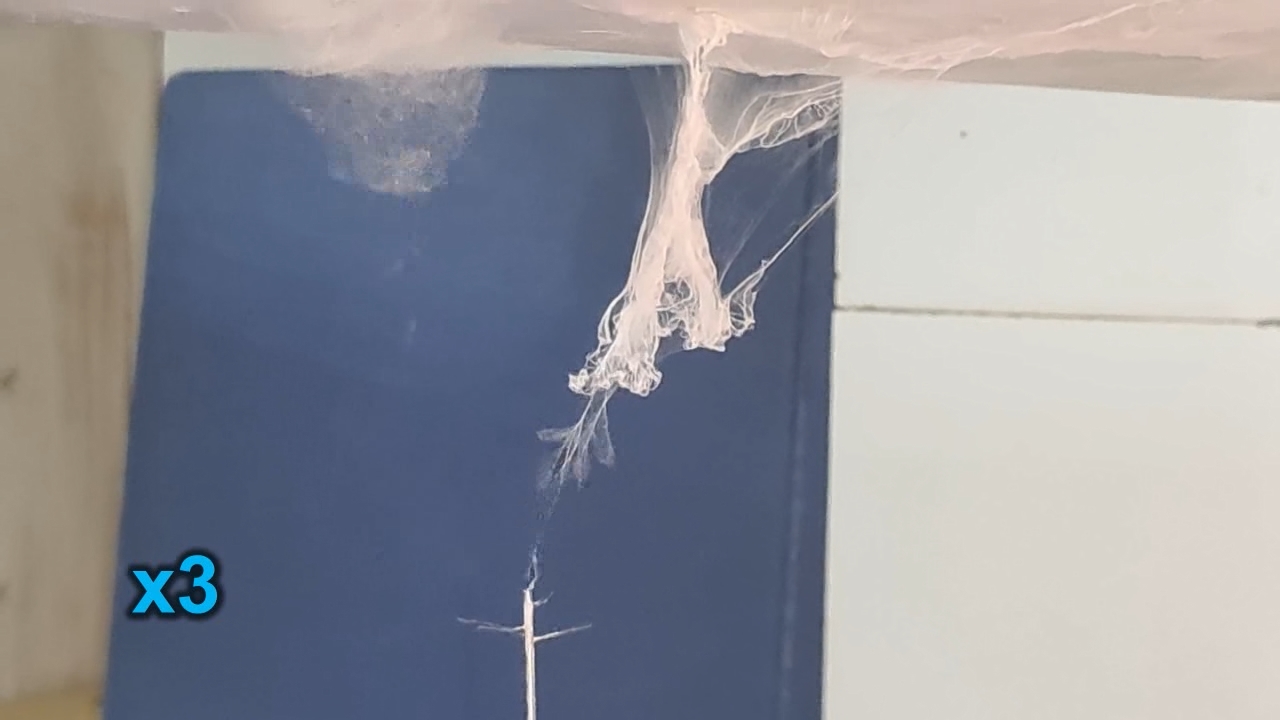

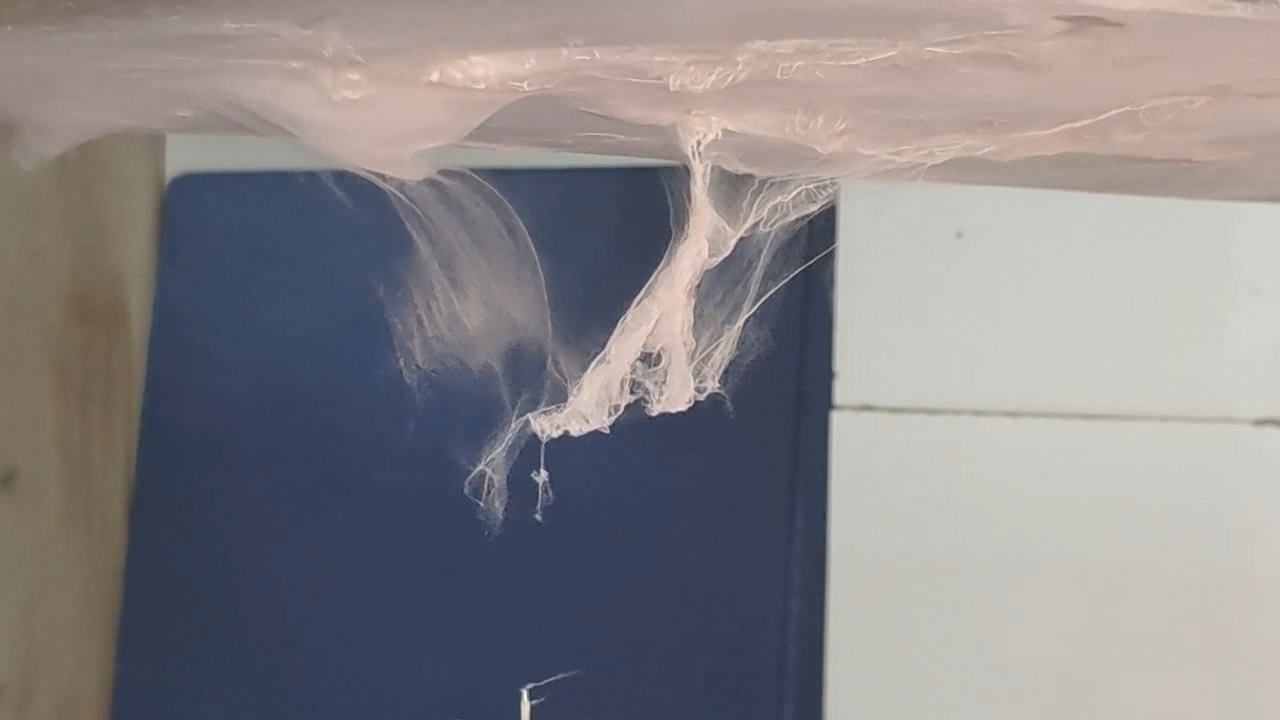

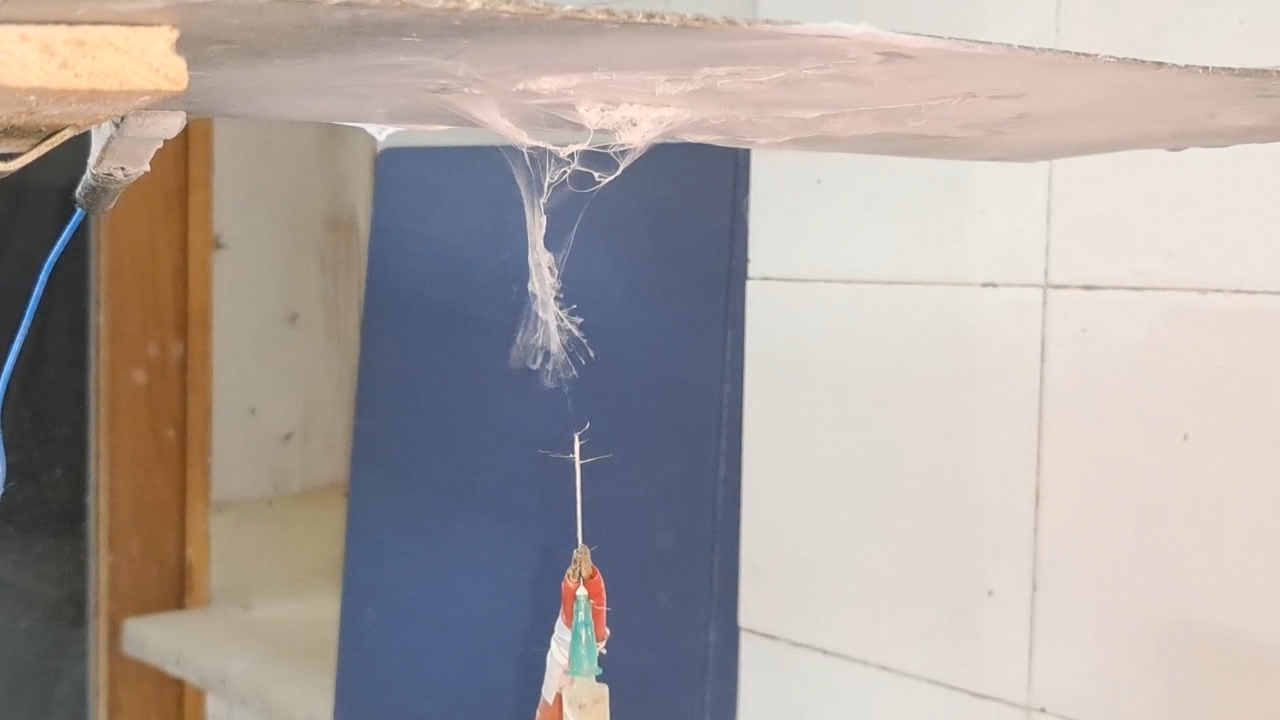

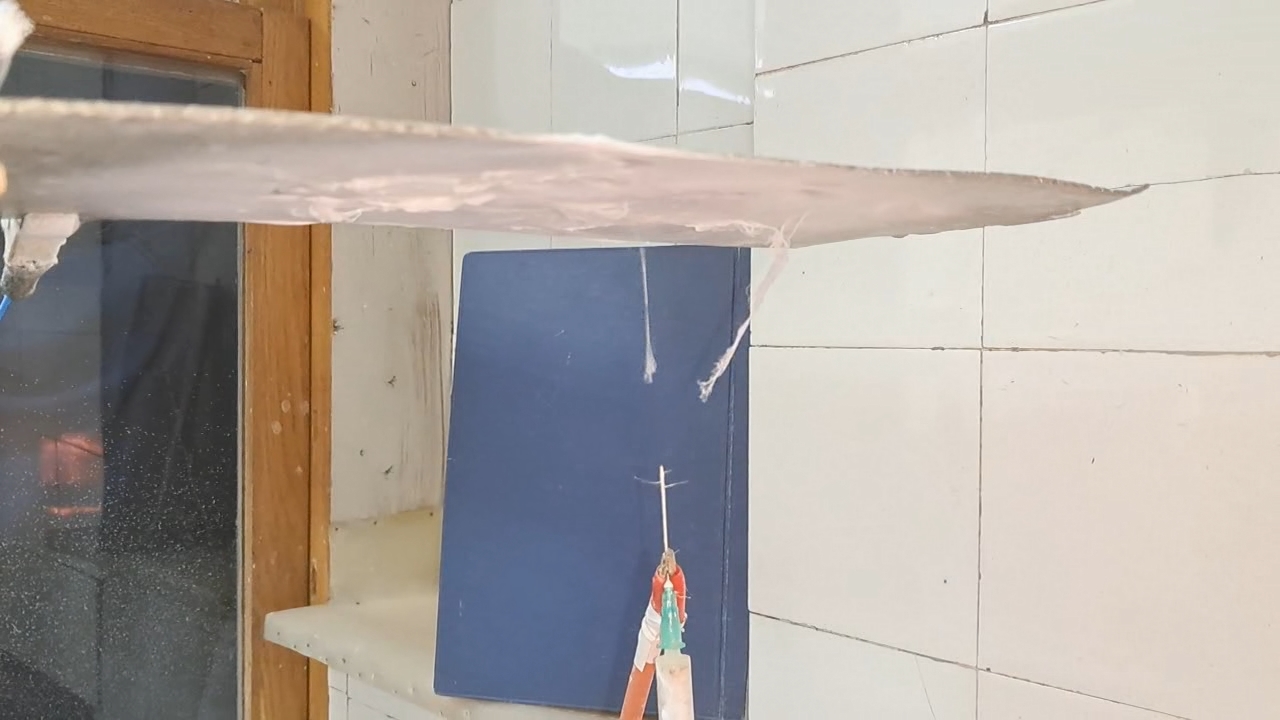

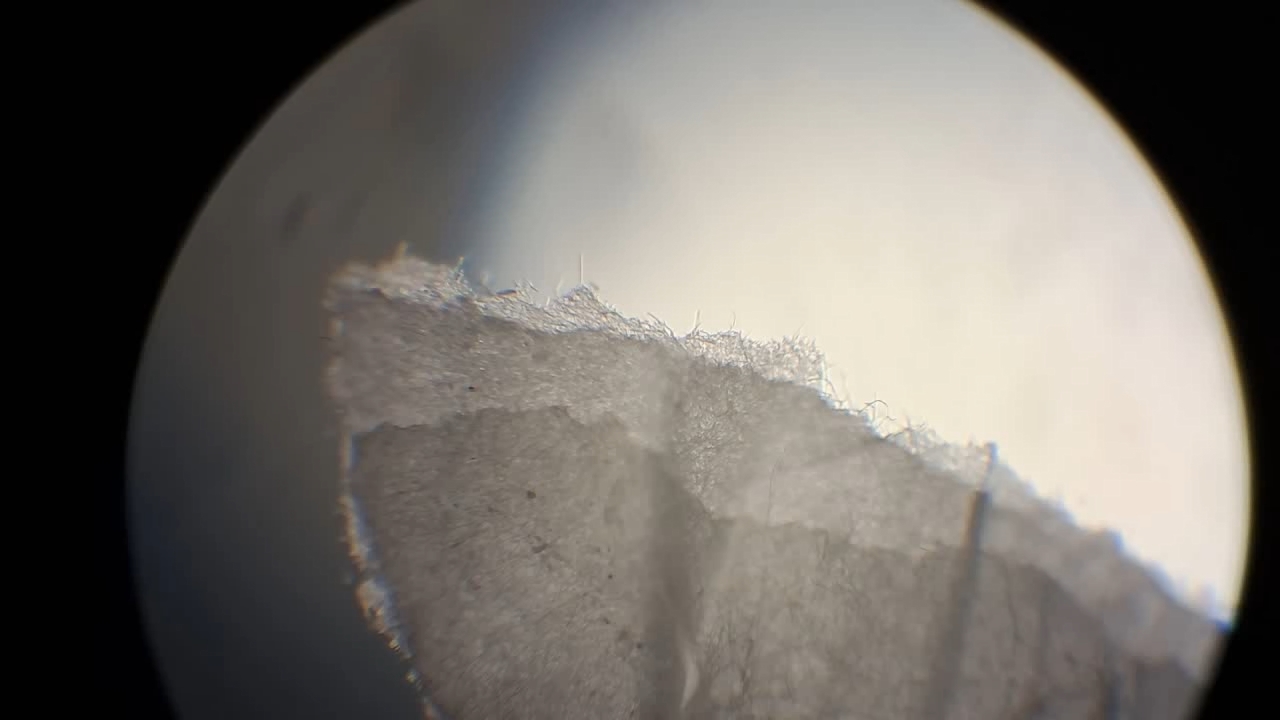

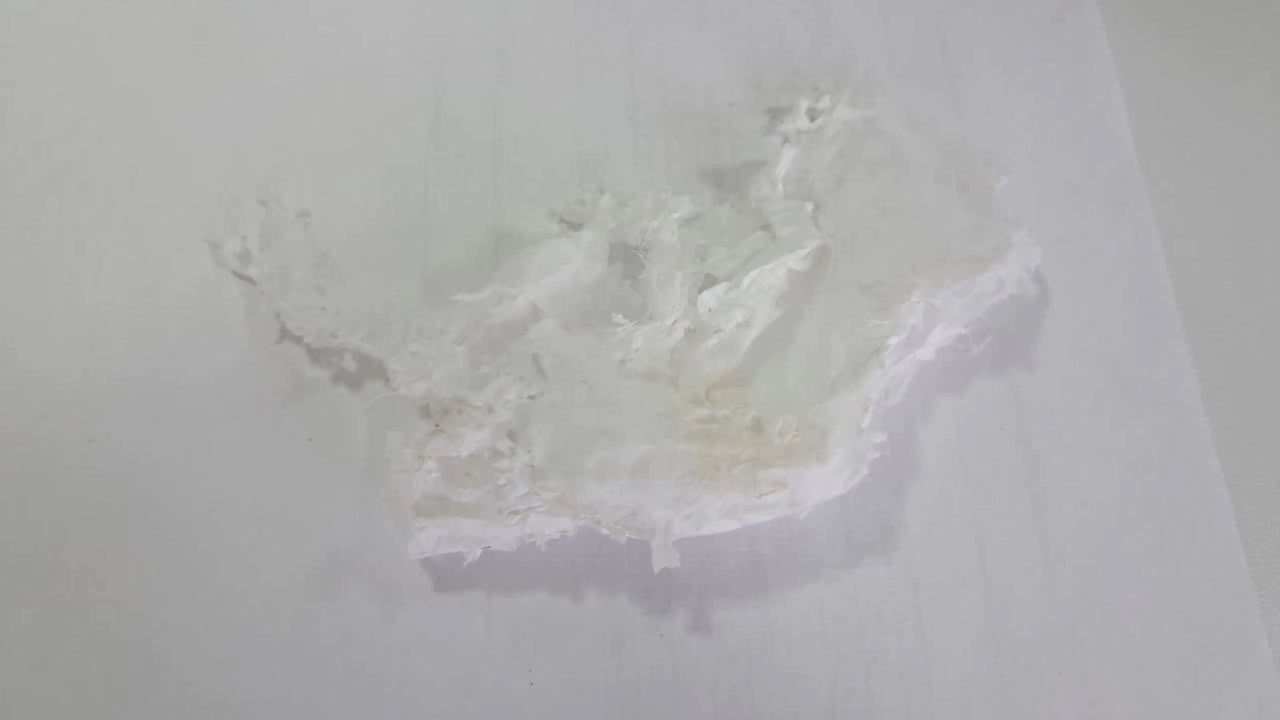

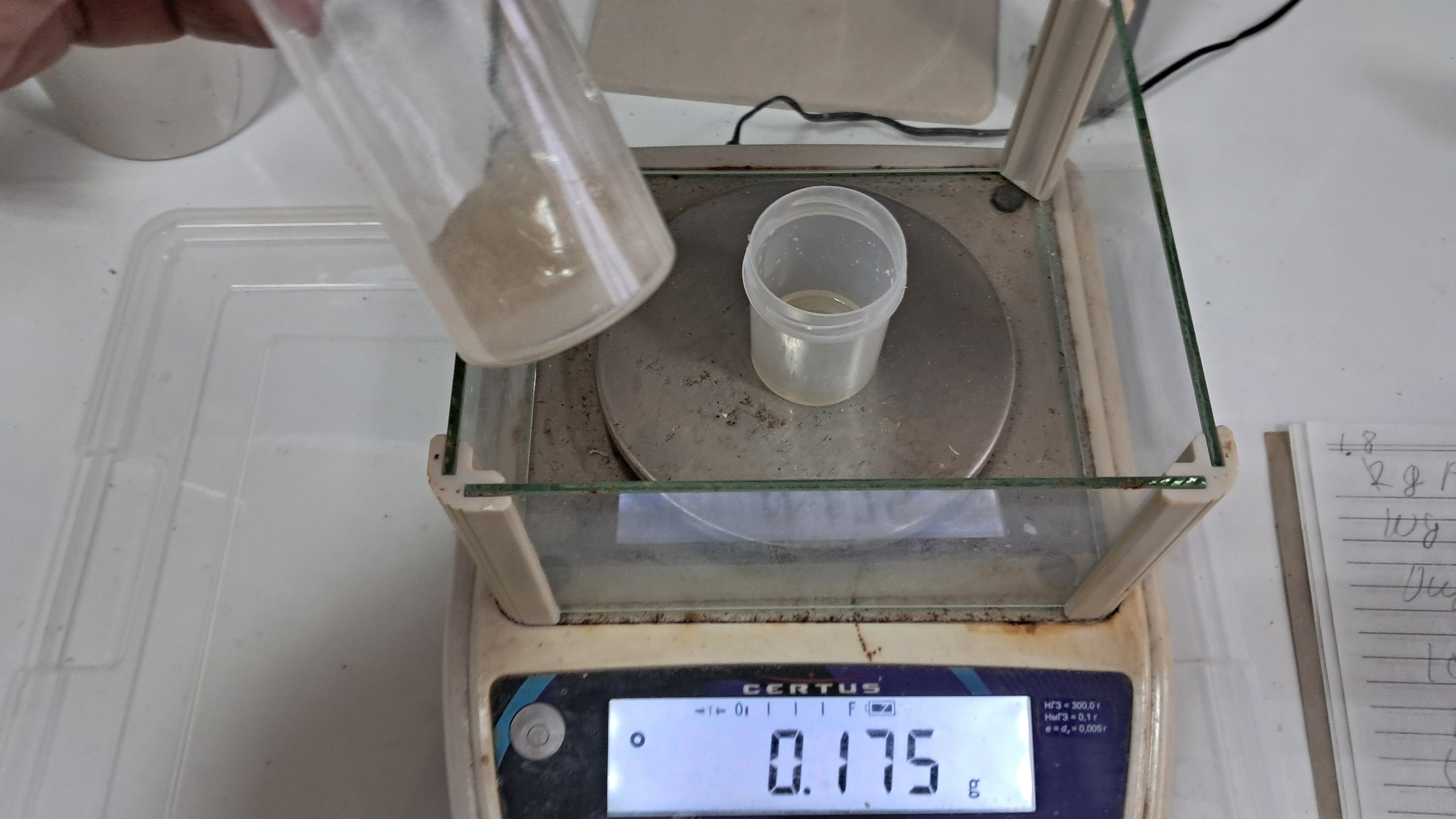

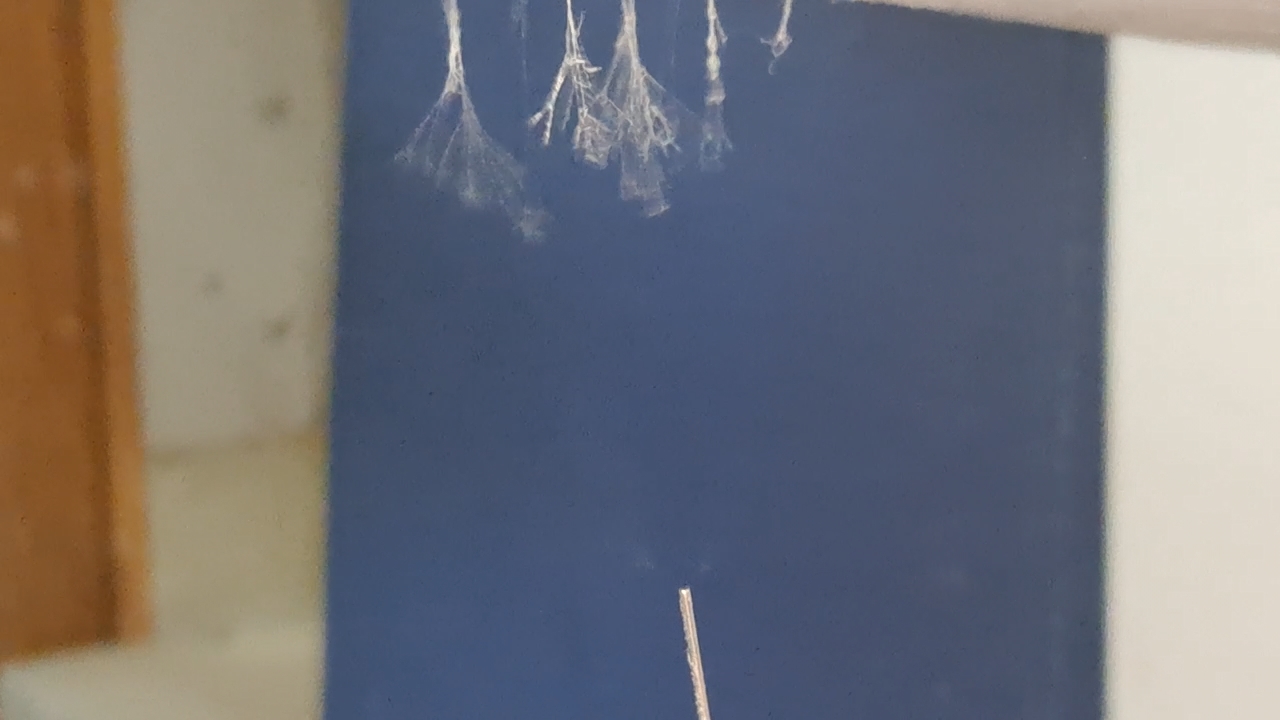

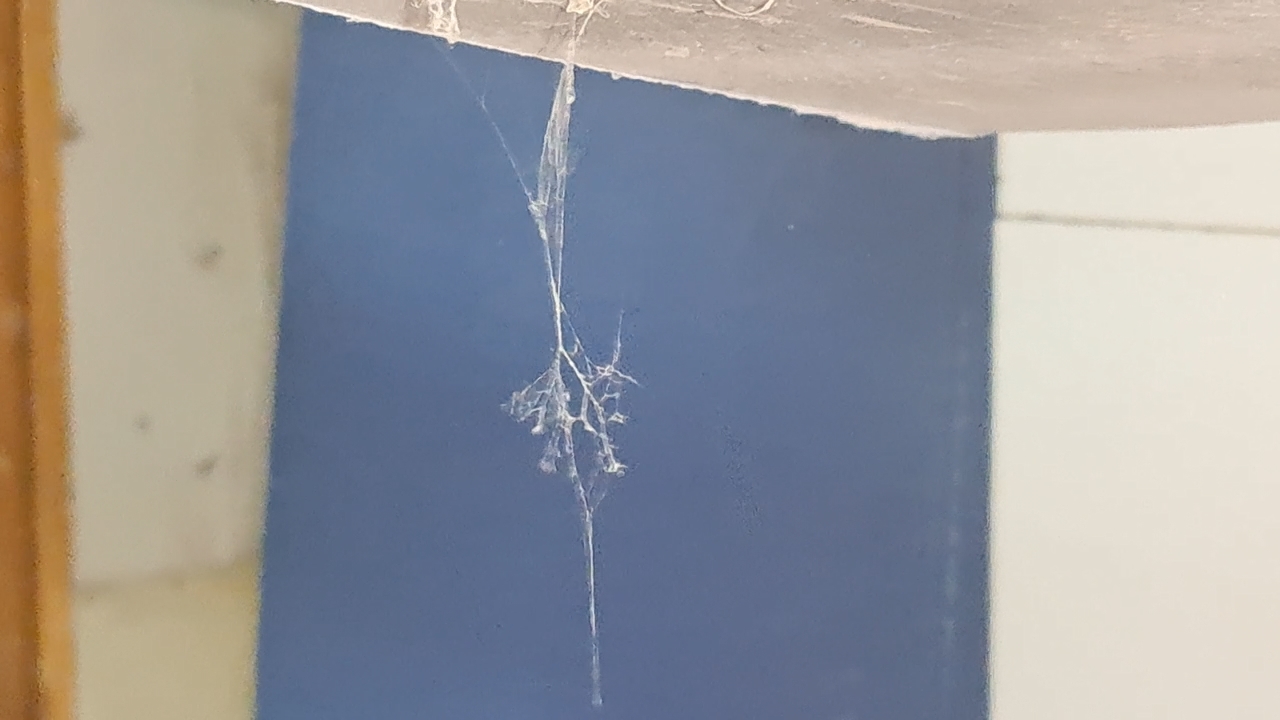

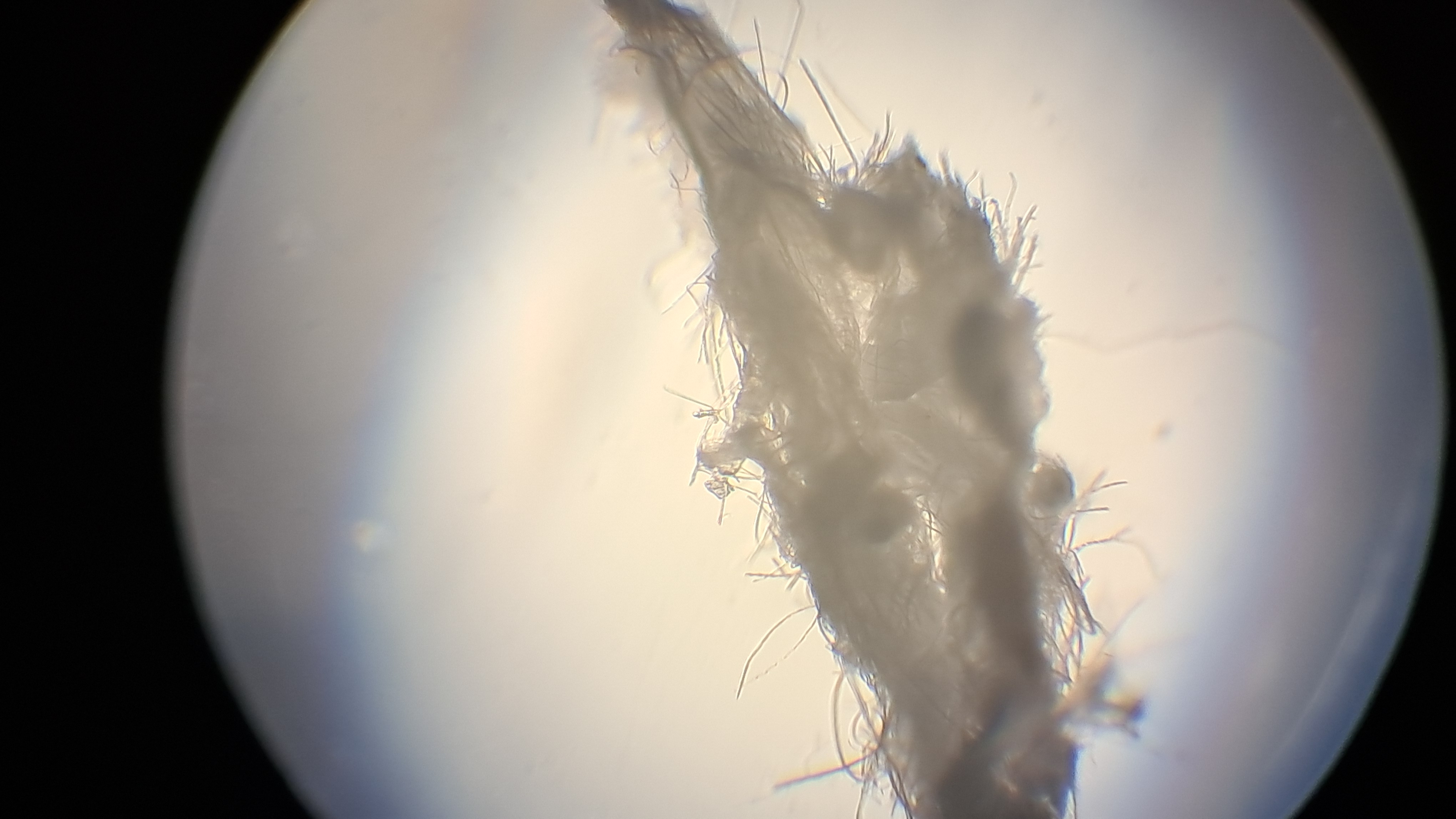

Электроспиннинг: раствор полистирола и поливинилендифторида в диметилформамиде - Часть 27 I mixed 0.175 g of a 28.9% polystyrene solution in DMF with 1.955 g of a 10.1% PVDF solution in DMF. The resulting polymer composition was 79.6% PVDF and 20.4% polystyrene. I then began electrospinning. A transparent, barely visible cone formed above the needle, consisting of either aerosol particles or jets of solution forming fibers. White dendritic structures, reminiscent of plant roots, extended from the collector toward the needle. This appearance closely resembled the electrospinning of a pure PVDF solution, which had not produced fibrous material. A significant difference, however, was that part of the collector became covered with a sparse "web" of fibers. Nevertheless, no continuous fibrous layer formed. This time, I could only dream of the "formation of cotton wool in the air" observed in previous experiments. Even with the naked eye, white "sand grains," representing solidified aerosol particles, were visible. Under a microscope, both fibers and numerous solidified aerosol particles could be observed. These were unevenly distributed: fibrous regions alternated with areas covered predominantly by solidified aerosol. Thus, electrospinning a polystyrene-PVDF mixture containing approximately 80% PVDF did not result in the formation of a desirable fibrous material. The electrospinning of PVDF and PVDF-rich polymer compositions likely requires a higher voltage. In our particular case, this would mean upgrading the setup with a new power source - either by repurposing another computer monitor or by constructing a voltage multiplier. This, however, will require waiting for the physicist to recover and return to work. |

Electrospinning: Solutions of Polystyrene (20.4%) and Polyvinylidene Difluoride (79.6%) in Dimethylformamide |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|