Chemistry and Chemists № 1 2026

Journal of Chemists-Enthusiasts

| Content | Chemistry experiments - video | Physics experiments - video | Home Page - Chemistry and Chemists |

|

Chemistry and Chemists № 1 2026 Journal of Chemists-Enthusiasts |

Electrospinning - pt.37, 38 Chemist |

|

Having noticed a mistake in the text, allocate it and press Ctrl-Enter

I dissolved polymethyl methacrylate (PMMA) in three different solvents: dichloromethane, tetrahydrofuran, and an "Acetone+" substitute. In all cases, the polymer initially swelled slowly. After several days or weeks, a solution formed, but it was too viscous for electrospinning. Diluting the viscous liquid with additional solvent proved impractical, as the viscosity remained high even when the polymer concentration was significantly reduced.

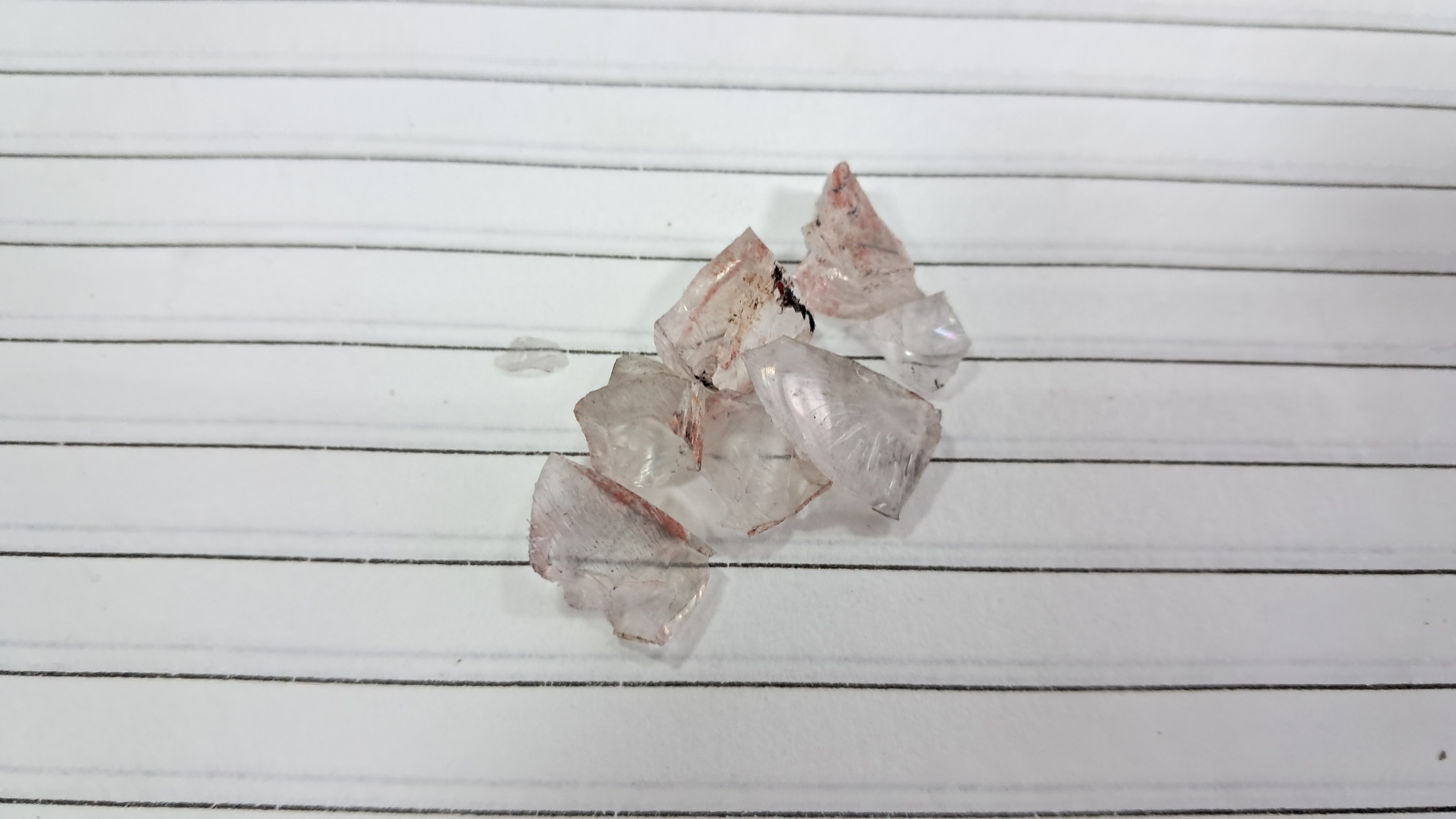

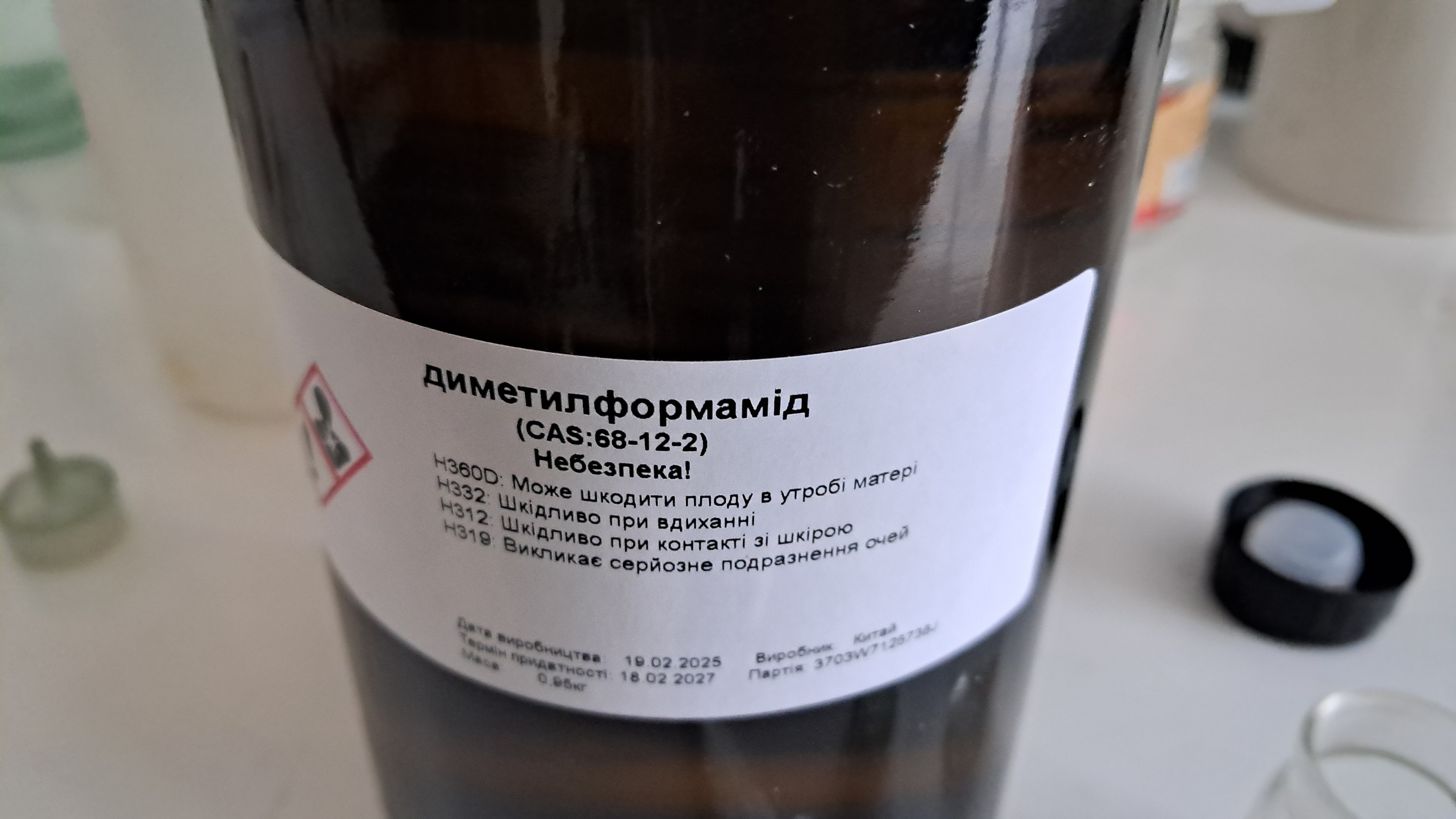

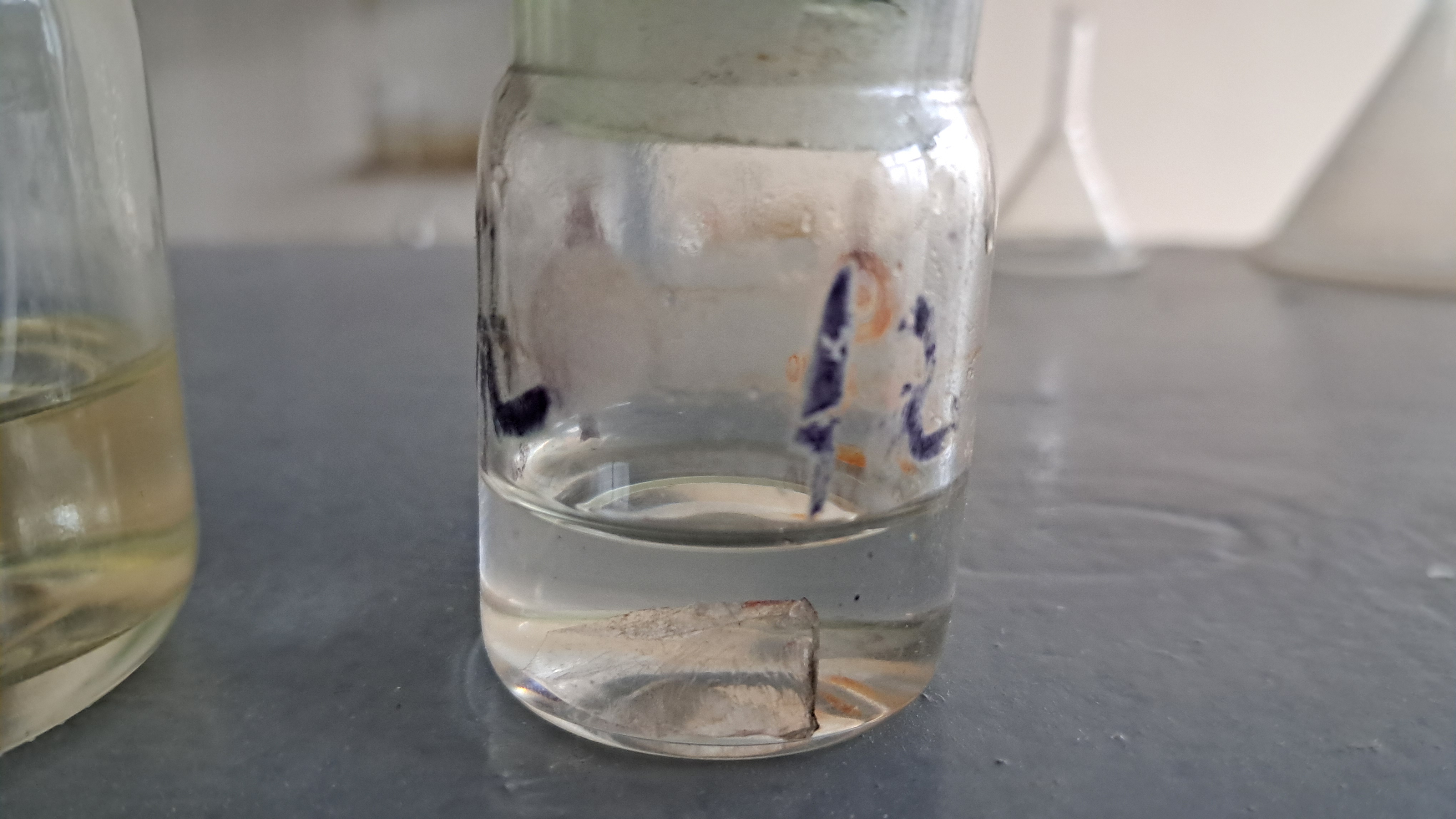

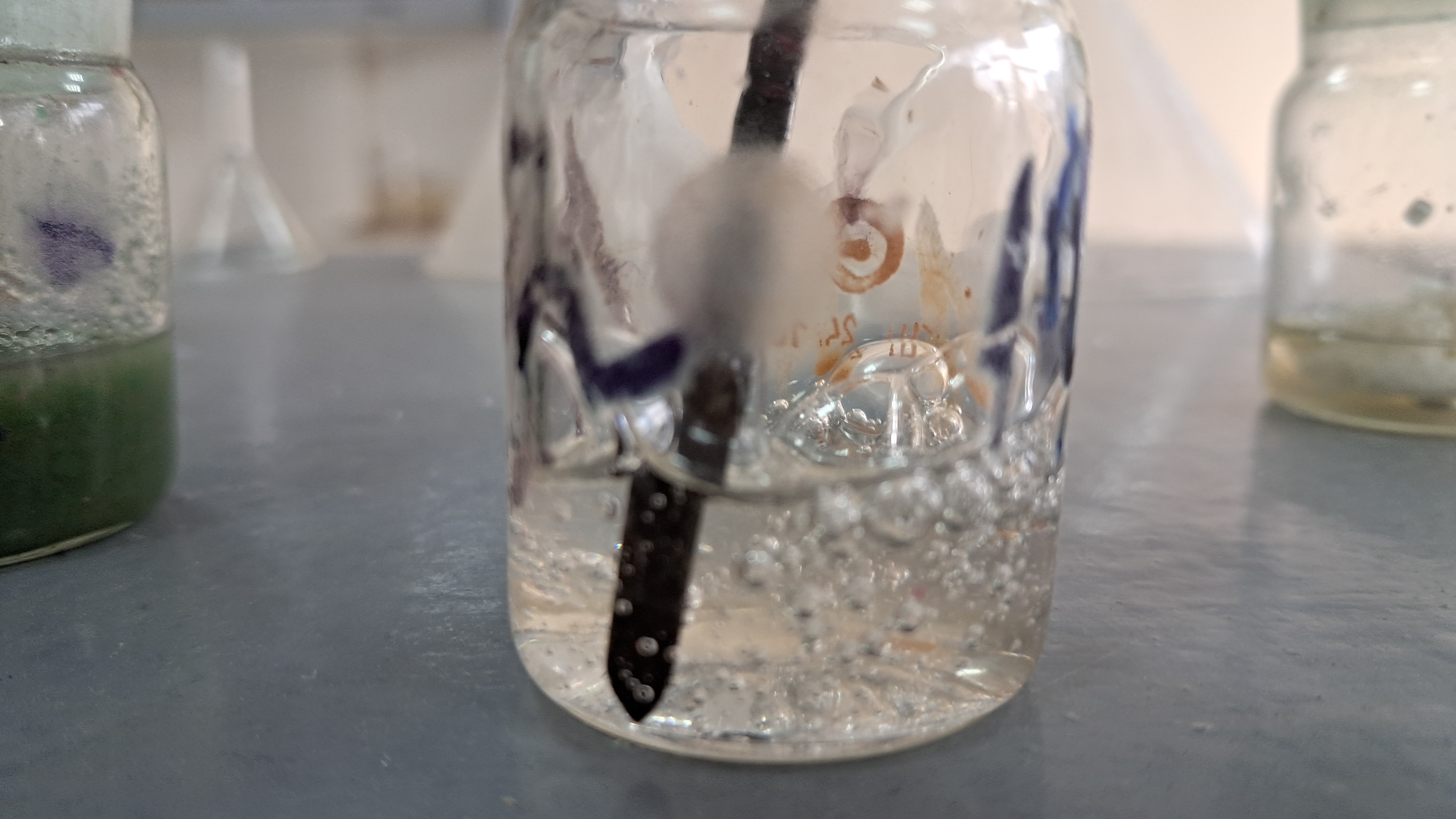

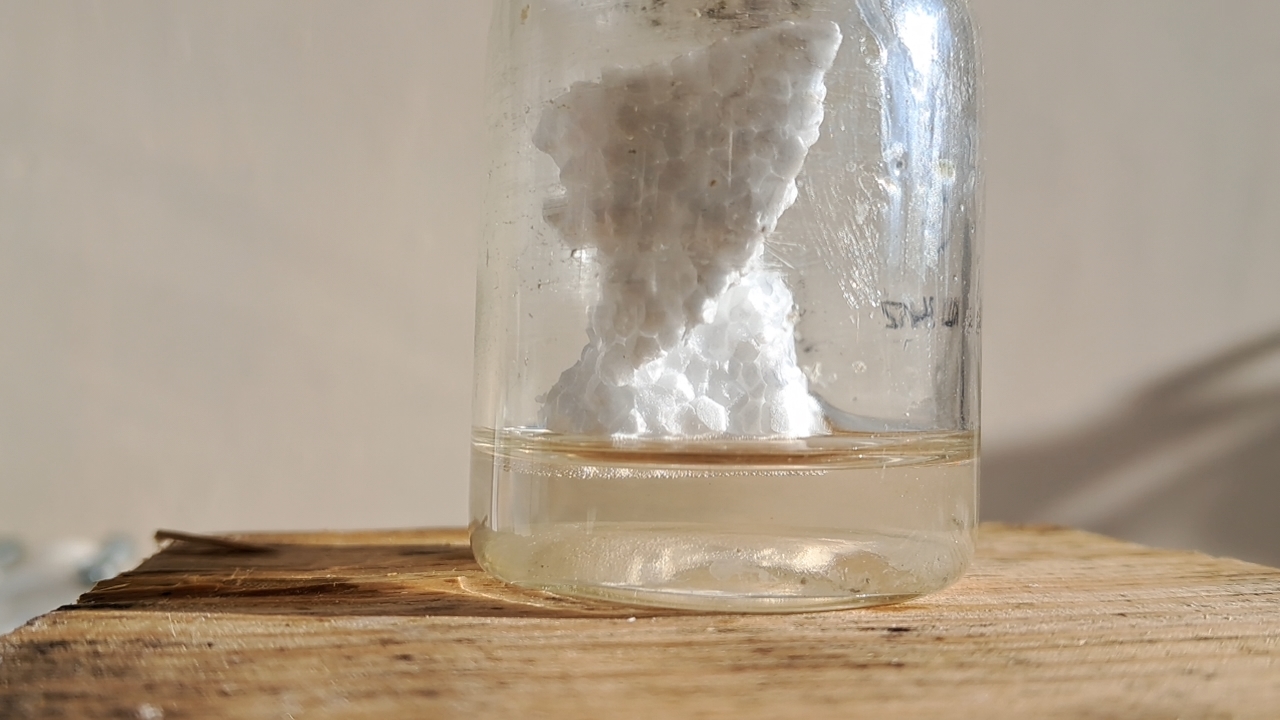

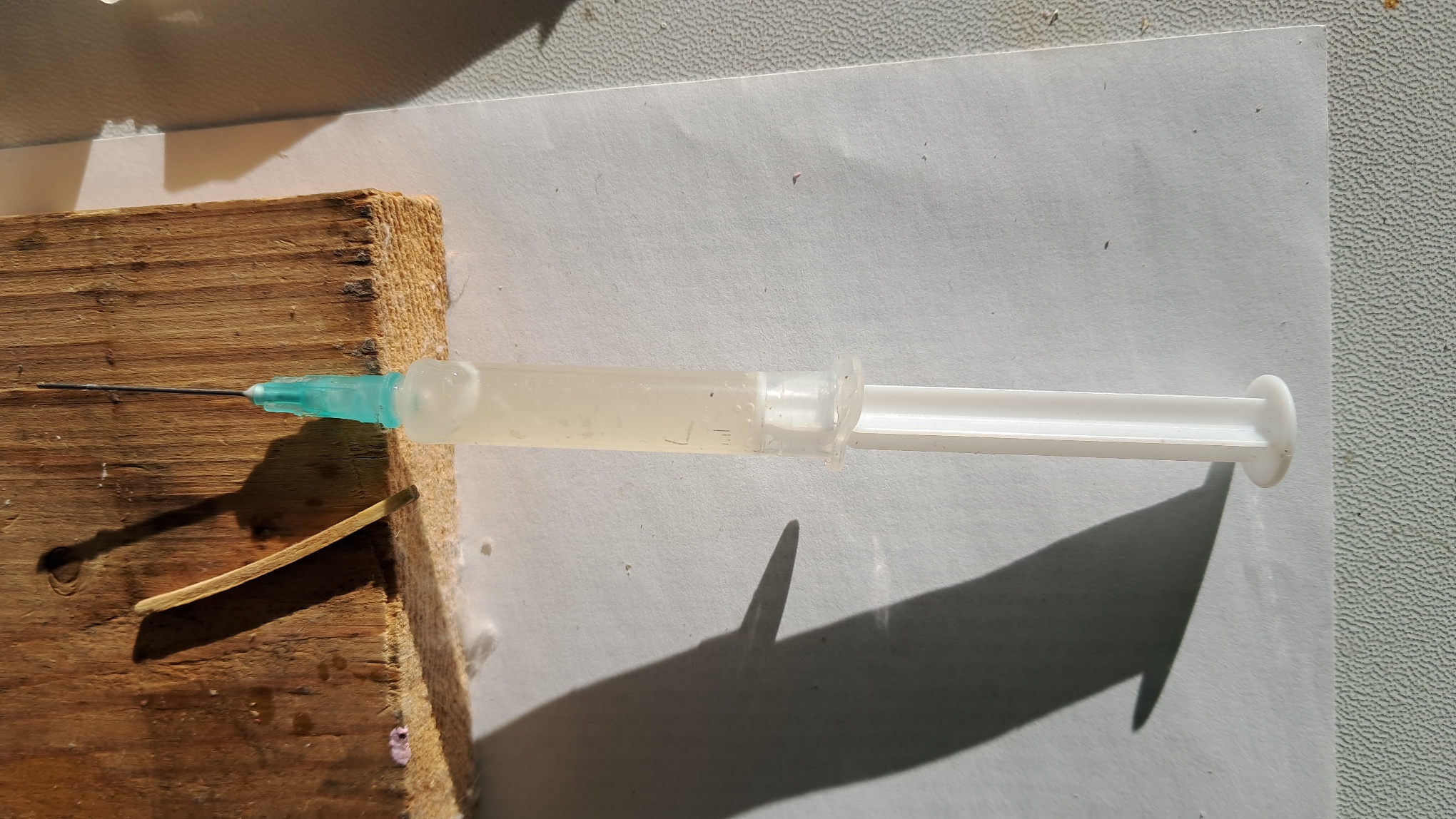

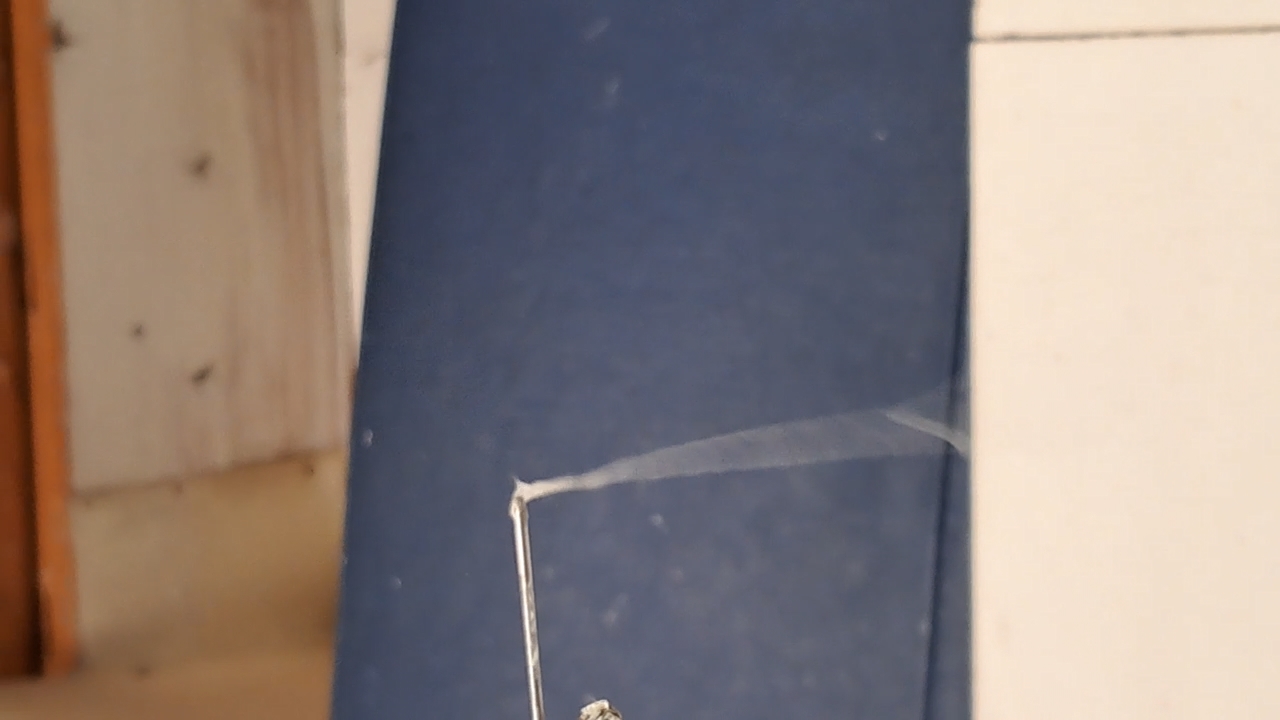

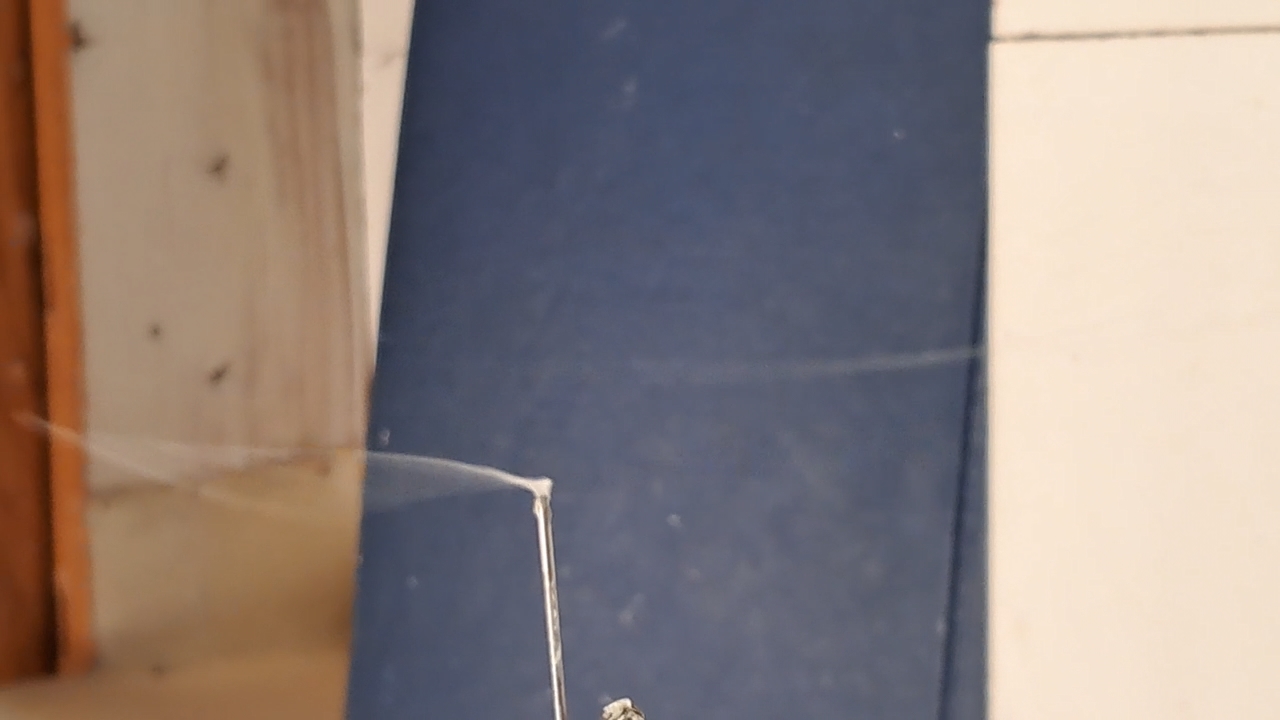

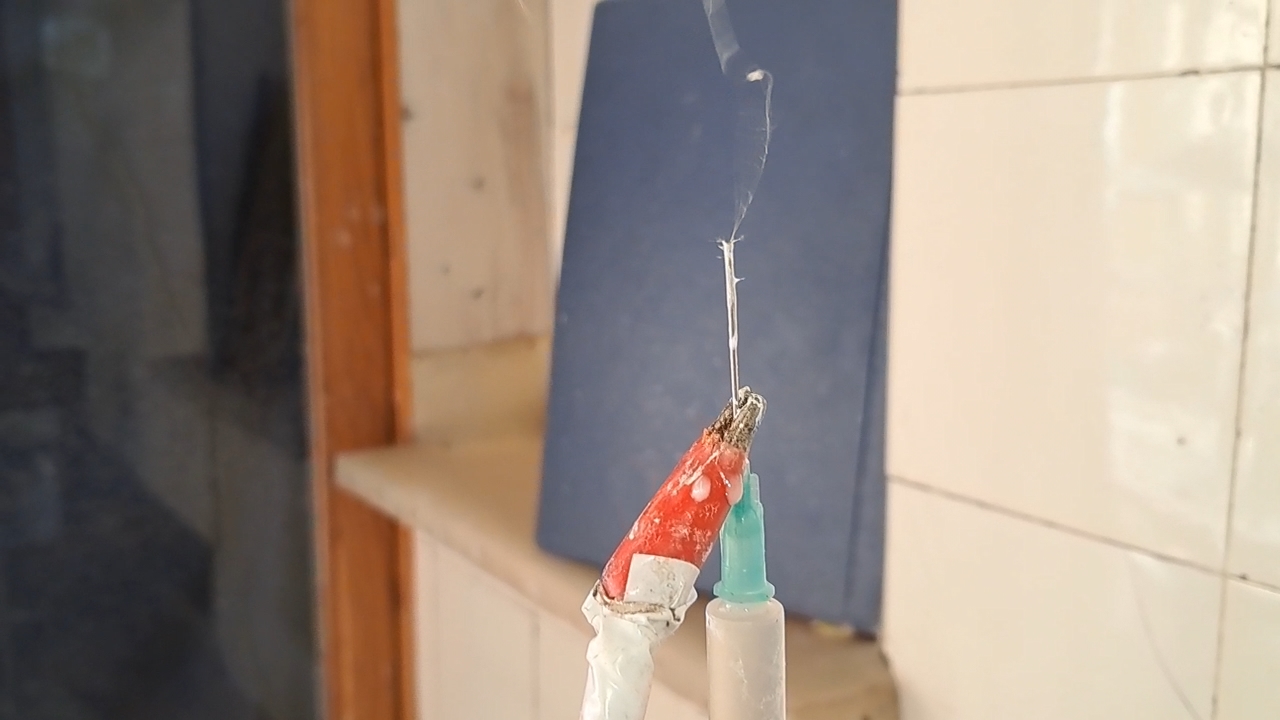

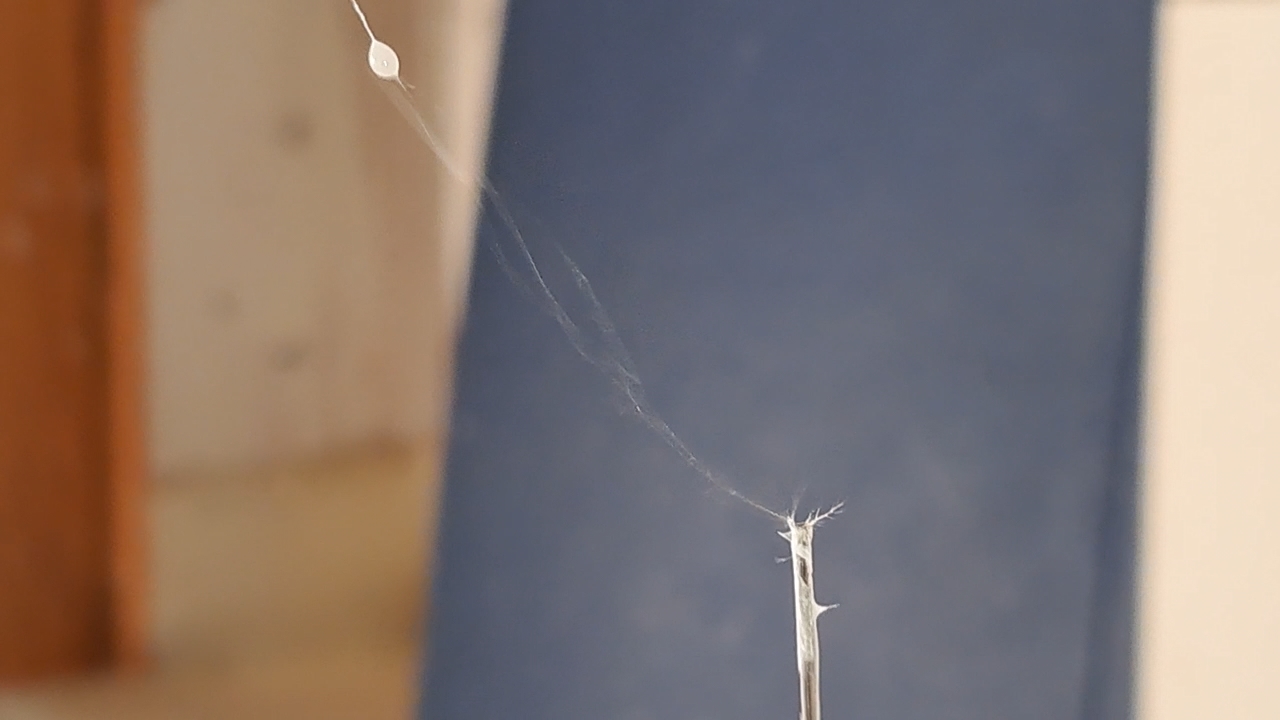

In previous experiments, I had unexpectedly discovered that a solution of polystyrene in DMF exhibited relatively low viscosity even at high polymer concentrations. This solution readily formed fibrous polystyrene during electrospinning. This observation suggested that a solution of PMMA in DMF might also possess acceptable viscosity at working polymer concentrations. I was not particularly hopeful, but this approach seemed preferable to purchasing diodes and other components and attempting to build high-voltage equipment for the first time in my life. I weighed out 0.250 g of PMMA. To do so, I had to enter the unheated laboratory and crush a piece of the polymer with a hammer. Due to severe and prolonged frost, the room temperature had dropped to -4°C. Not only the windows but also the ceiling and walls were covered with a thick layer of frost. It was a depressing sight. After all, this was not an abandoned storage room, but a chemistry laboratory containing equipment that could fail under such environmental conditions. I returned to the heated laboratory and weighed out 5.000 g of DMF. The substances were placed in a small bottle, and the cap was sealed tightly. Dissolution required several days. The polymer gradually swelled and lost its transparency. To accelerate the dissolution of PMMA, I stirred the mixture occasionally. Eventually, a clear, colorless solution of PMMA in DMF formed. Despite the relatively low polymer concentration (5%), the liquid remained too viscous for electrospinning. Nevertheless, I decided to conduct the experiment. The result was remarkable. A long, thick stream of polymer solution rotated above the needle, unable to detach from the tip and reach the collector. The stream resembled a spinning helicopter propeller. When the far end of the stream finally touched the collector, its rotation continued. One end remained attached to the needle, while the other adhered to the collector. Naturally, electrospinning was out of the question. The "helicopter simulator" was visually interesting, but it could not produce electrospun PMMA. The solution was excessively viscous. The stream of solution was approximately 1 mm thick. Compared with thin microfibers, it resembled a veritable "rope" or even a thick "cable." I then added another 5 g of DMF to the solution, mixed it thoroughly, and repeated the electrospinning attempt. This time, the "helicopter effect" was not observed. As before, fibers connected the needle and the collector, but they were thinner. The collector became coated with a viscous liquid - the solvent had not completely evaporated. Some of the solution did not reach the collector but was instead scattered in all directions. The experiment had to be terminated. |

Electrospinning: Solution of PMMA in DMF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Having noticed a mistake in the text, allocate it and press Ctrl-Enter

Electrospinning: Solution of PMMA and Polystyrene in DMF - Part 38

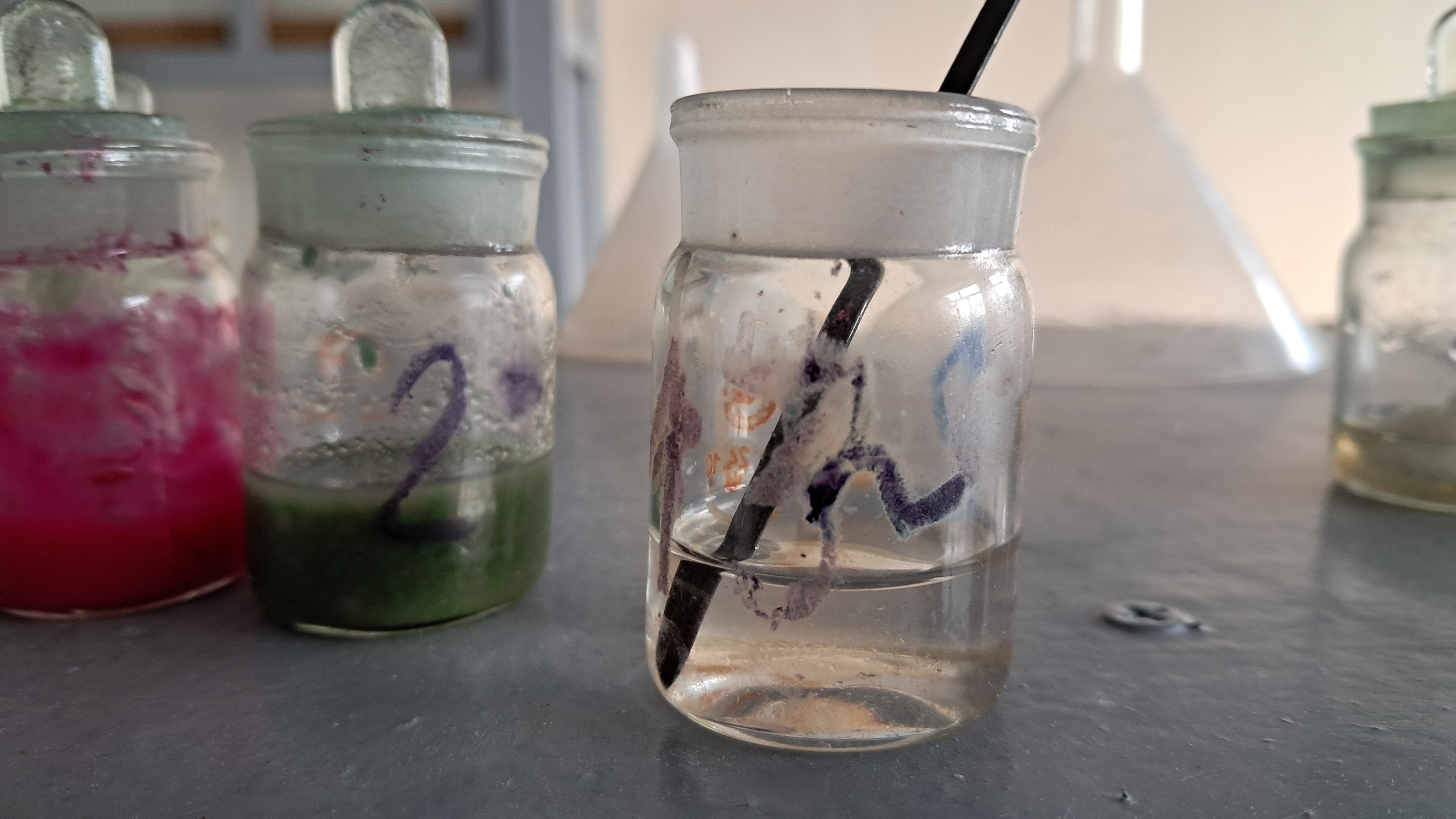

The solution of PMMA in DMF proved unsuitable for electrospinning. The original solution was excessively viscous. When I diluted it with additional DMF and attempted electrospinning, a viscous liquid accumulated on the collector instead of forming fibrous polymer. I wondered whether adding polystyrene might promote fiber formation. I would not have initially attempted this experiment, but I had some diluted solution of PMMA in DMF left over from a previous trial.

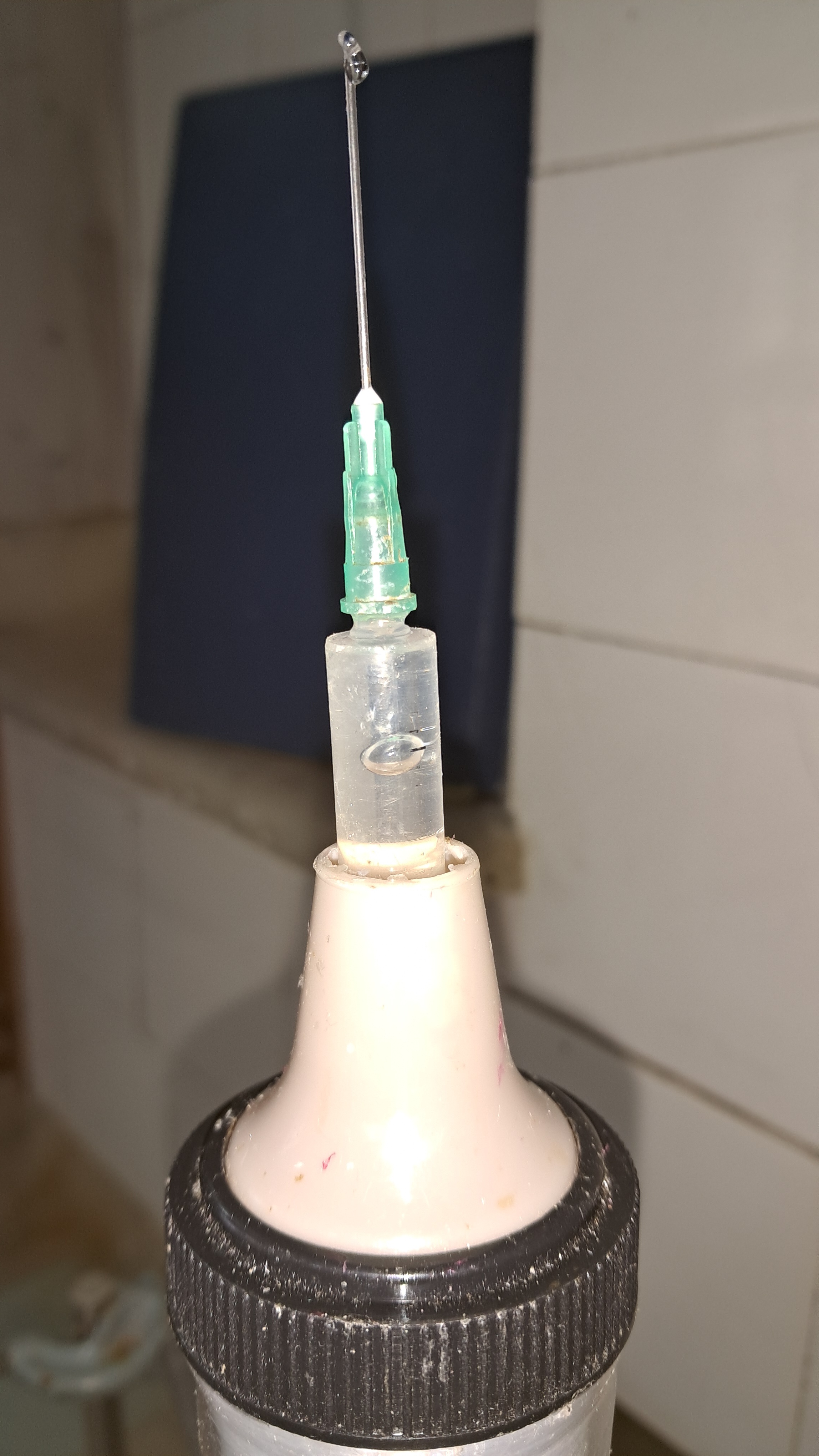

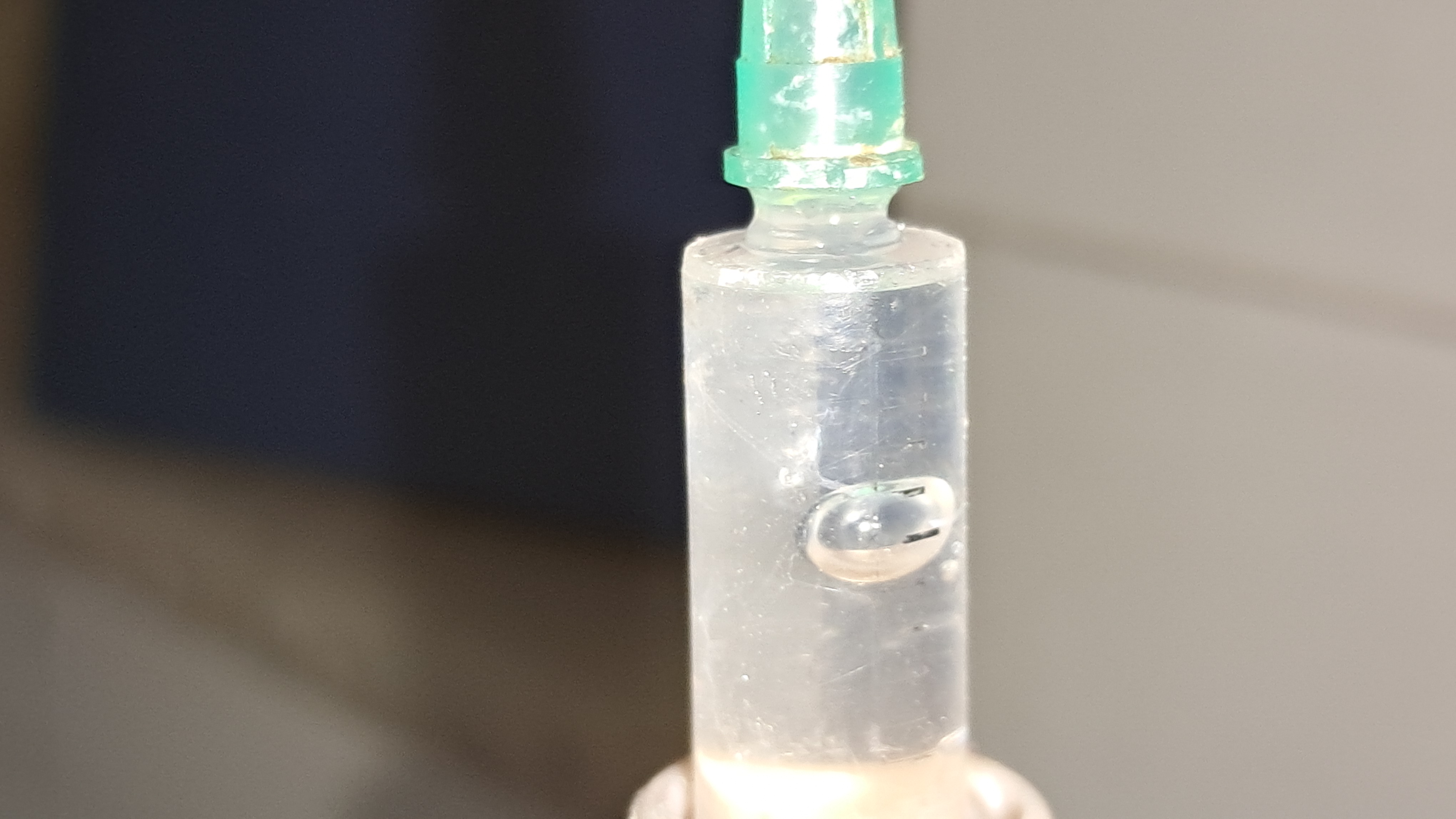

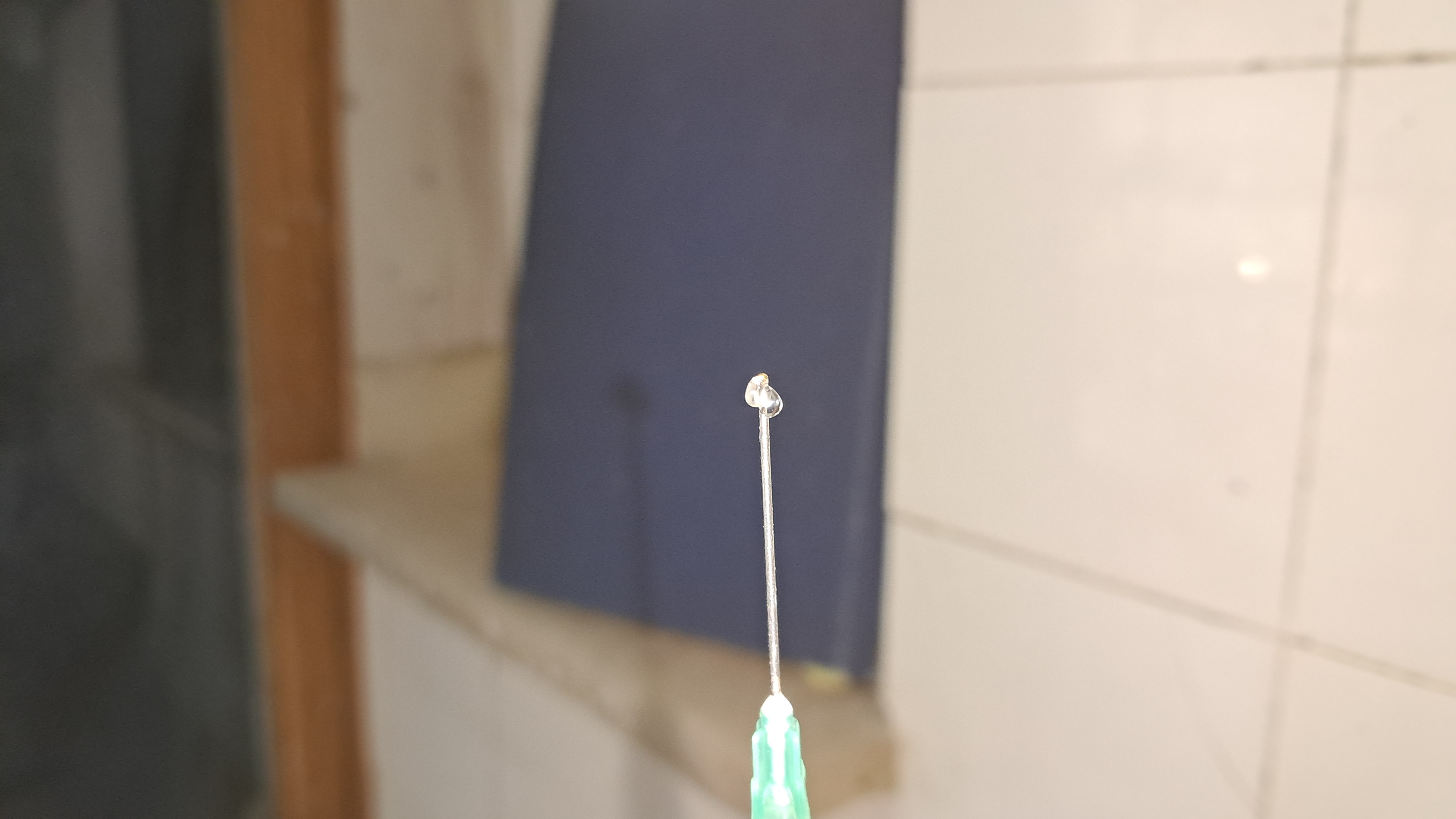

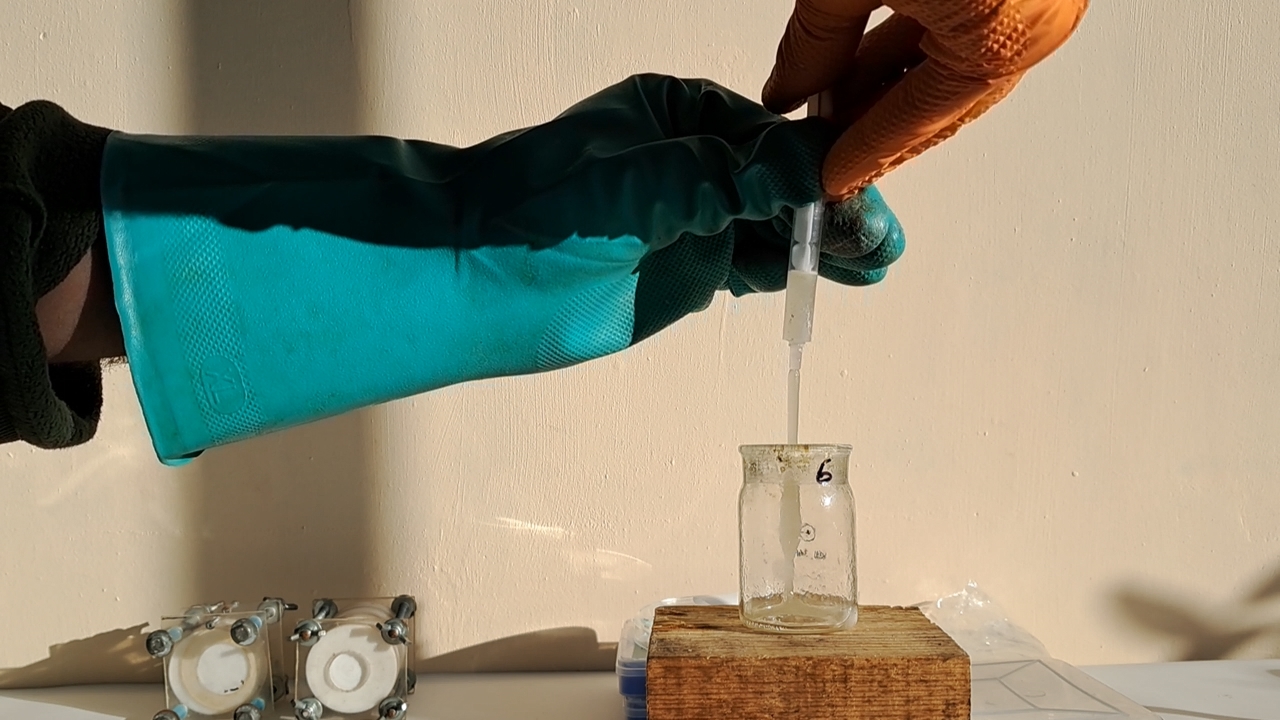

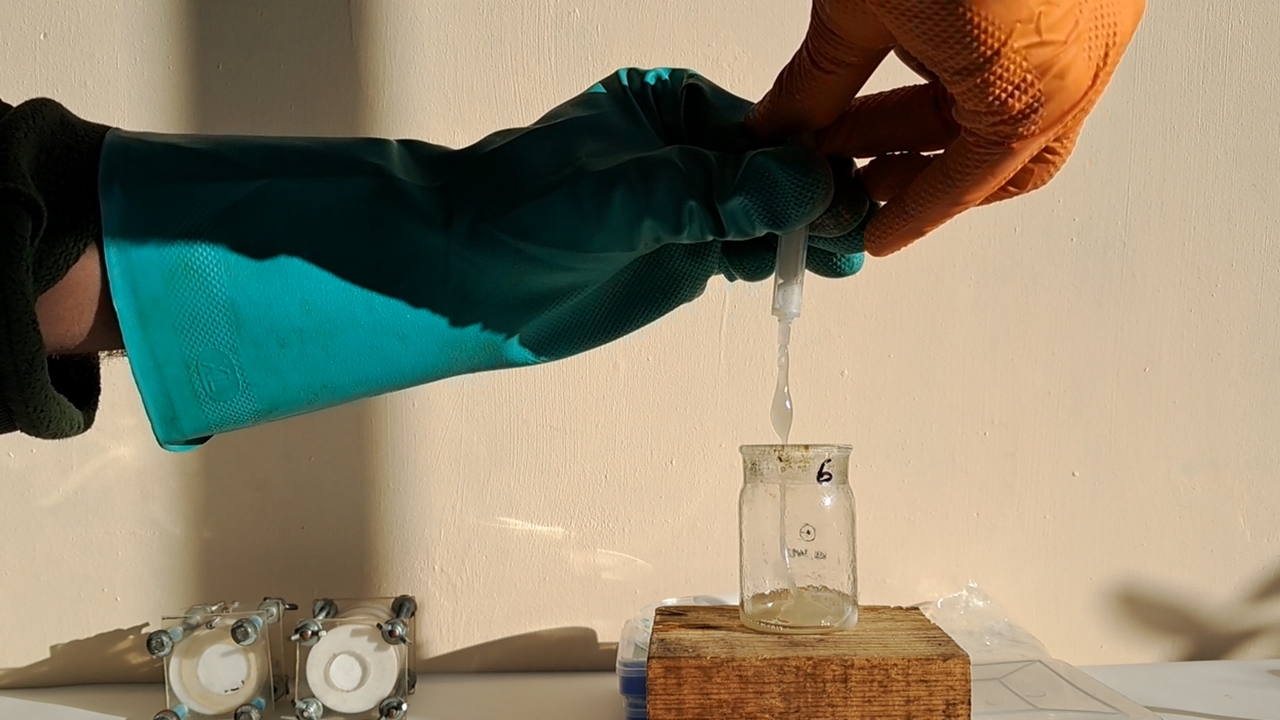

Электроспиннинг: раствор PMMA и полистирола в DMF - Часть 38 I weighed 6.490 g of the PMMA solution in DMF and 1.005 g of expanded polystyrene. The polystyrene was added to the liquid in small pieces while stirring vigorously until it dissolved. A white, viscous solution formed. I began electrospinning, but the "helicopter effect" reappeared. The liquid was still too viscous. I stopped the process, added another 3 g of DMF to the solution, and resumed electrospinning. Thinner threads now formed, connecting the needle and the collector. Approximately halfway between the electrodes, large droplets of solution formed along the fibers. Sometimes these droplets were drawn toward the collector; at other times, they were dispersed in all directions. I could not help recalling the earlier experiment with chitosan in acetic acid, when droplets of solution struck my face because I had not been wearing protective goggles. This time, I did not repeat that mistake and immediately put on my goggles as soon as I saw the solution scattering. Continuing the experiment was pointless. Every PMMA-containing solution tested proved unsuitable for electrospinning. A few words should be said about the rheological properties of the PMMA-polystyrene solution in DMF used in these experiments. The most accurate, though inelegant, description of this liquid would be "mucus-like." I tried to find a more scientific term. The first concept that came to mind was "non-Newtonian fluid." However, a non-Newtonian fluid typically behaves like a solid under rapid deformation and flows like a conventional liquid under slow deformation. Our solution exhibited the opposite behavior. It flowed when sufficient force was applied but partially retained its shape when the external force was removed. Essentially, this corresponds to the behavior of a plastic solid. In other words, this material occupied an intermediate state between a swollen polymer and a true polymer solution. This was the final electrospinning experiment conducted to date. Everything described in this article was carried out purely out of enthusiasm. Two of my colleagues constructed the electrospinning setup, which I used for several months. Whether we will be able to continue this work remains uncertain. We have now been offered a completely different project, promising funding, appropriate equipment, and even a new laboratory. Time will tell how serious this proposal is. If the offer proves genuine and we accept it, there will likely be no creative freedom when working on the new topic - nor even the opportunity to document our daily laboratory routine. |

Electrospinning: Solution of PMMA and Polystyrene in DMF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|