Chemistry and Chemists № 3 2025

Journal of Chemists-Enthusiasts

| Content | Chemistry experiments - video | Physics experiments - video | Home Page - Chemistry and Chemists |

|

Chemistry and Chemists № 3 2025 Journal of Chemists-Enthusiasts |

Repair of Condenser for Distillation in Unsuitable Conditions Chemist |

|

Having noticed a mistake in the text, allocate it and press Ctrl-Enter

Repair of Condenser for Distillation in Unsuitable Conditions

As part of a research project, it became necessary to synthesize a certain ester with a relatively simple molecular structure. As is known, esters are usually obtained by reacting a carboxylic acid with an alcohol in the presence of sulfuric acid. The acid acts as a catalyst and a dehydrating agent, shifting the reaction equilibrium toward ester formation (the article has not yet been published, so it is too early to reveal the details).

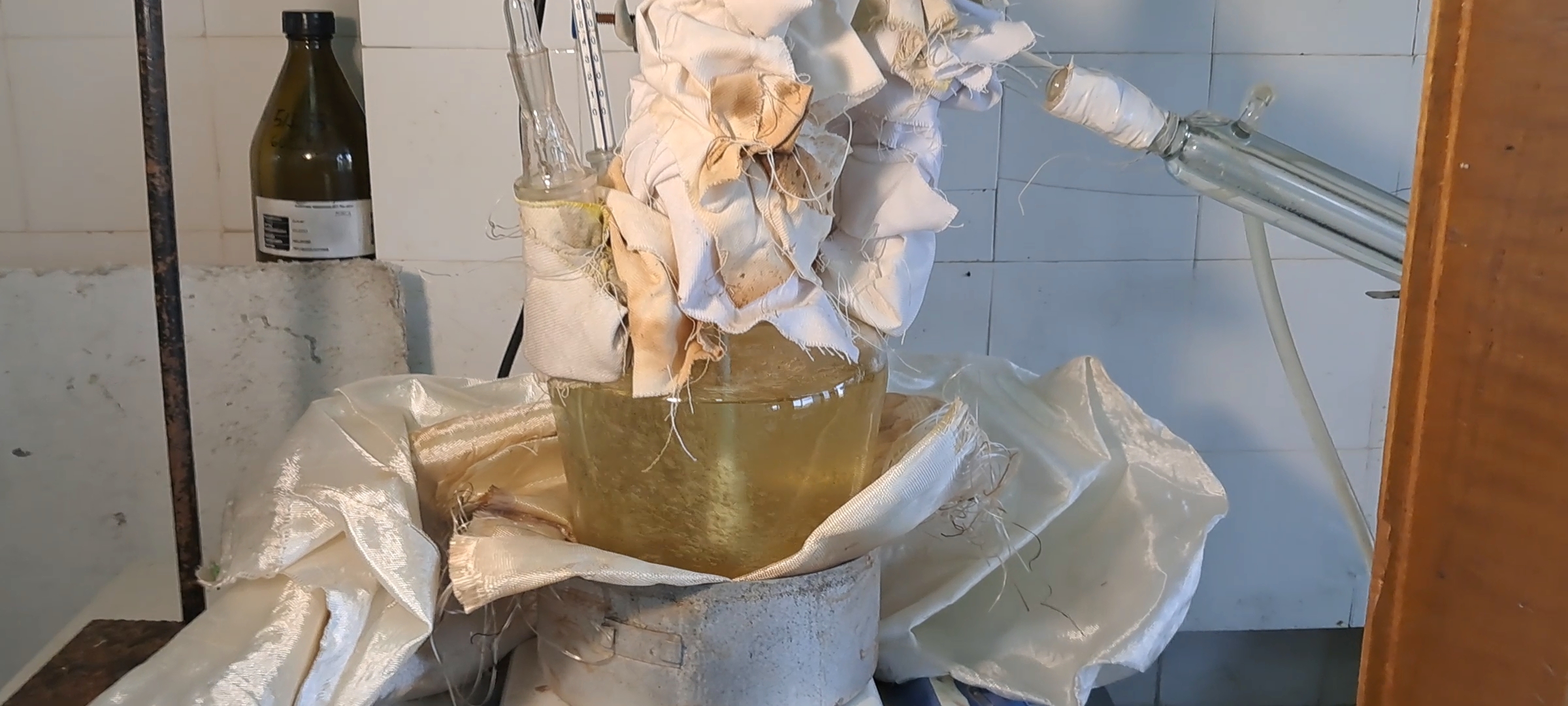

Ремонт холодильника для перегонки в неприспособленных условиях I searched the literature and found a rather inconvenient synthesis method. It turns out that both the ester and even the starting alcohol undergo irreversible decomposition upon exposure to the corresponding acid. The presence of sulfuric acid only worsens the situation. Therefore, indirect methods are usually employed to prepare this ester. Further literature search showed that a direct reaction between the acid and alcohol is still possible but requires specific conditions. In particular, the ester must evaporate from the reaction flask as quickly as possible, after which its vapors should be cooled rapidly to condense them. I assembled a setup that looked much like a standard distillation apparatus. After several small-scale trial syntheses with mixed results, I decided to scale up. For the first experiments, I used a Liebig condenser with 14/23 ground joints. For the larger reaction flask, I needed a condenser with a wider vapor tube - otherwise, the ester would accumulate in the flask, decompose, and reduce yield. The only condenser I could find had 19/26 ground joints, but even here, the internal diameter of the joint limited the rate of vapor removal. I had no choice but to use it. When I scaled up again, I used a four-neck flask almost three times larger than before. As in previous syntheses, I first inserted the stirrer shaft through the central neck and the distillation adapter. After assembling the setup and attaching the condenser, I discovered that the stirrer shaft was too short for this larger flask. To fix the problem, I disconnected the condenser and adapter, installed a short adapter for the stirrer shaft, and inserted the distillation adapter into one of the two side necks of the flask - one straight and the other curved at a right angle. I chose the straight one without paying attention to its intended purpose. After reattaching the condenser, I attempted to install the dropping funnel, only to realize that it would not fit into the curved neck. The straight neck was meant for the funnel, not the condenser. Reluctantly, I detached the condenser once more and attempted to connect it to the curved neck. This operation is always unpleasant: the ground glass joints are fragile, and even slight misalignment can break them. To connect the condenser, the ground glass joint of the adapter must be inserted snugly into the condenser joint, after which the condenser is fixed in a retort stand. Any distortion or excessive force can easily crack the glass, especially if the axes of the adapter and condenser do not align perfectly. For the third attempt, I carefully aligned the joints, inserted the adapter into the condenser, pressed lightly - and the condenser's ground joint cracked. A fragment of glass flew off. Refusing to accept reality, I tried connecting it once more, and another piece of glass broke off. I had to revert to the narrower condenser I had used before. The synthesis succeeded, but the yield was noticeably lower. I had broken my only suitable wide-bore condenser. Chemists often try to prevent breakage by wrapping the "male" ground joint with thin PTFE tape (plumber's tape) to improve sealing and reduce stress. I had done so, but it did not help. Normally, a broken condenser can be repaired: the damaged joint is cut off or unsoldered, and a new ground joint is fused in its place - a simple task for a skilled glassblower. Unfortunately, neither our institute nor nearby institutions employ glassblowers anymore. In the past, every chemical institute or university chemistry department had one, but now they are rare. Buying a new condenser was not prohibitively expensive, but delivery would take time, and I doubted the project manager would approve the unplanned expense. In what could be called "stubborn denial of reality," I decided to try gluing the broken joint. The pieces were glued with liquid glass (an aqueous solution of sodium and potassium silicates). The problem was that condensers operate under temperature gradients that could easily destroy the adhesive joint and cause leaks. Even intact ground glass joints are fragile - a glued joint is even weaker. Nevertheless, I proceeded. I wrapped the "male" adapter joint in thin polyethylene film and inserted it into the broken condenser joint. I applied liquid glass to the broken edges and carefully set the separated fragments back in place. The adapter supported the fragments so they would not fall inward. The polyethylene film prevented the condenser from sticking permanently to the adapter. After waiting a while, I coated the entire outer surface of the joint with liquid glass. Once dry, I applied a second layer of liquid glass, wrapped the joint with fiberglass, and impregnated it with more liquid glass. The fiberglass served as reinforcement. I also asked a colleague about the heat resistance of silicone sealant; he assured me that it would withstand 200°C - sufficient for my conditions. He coated the fiberglass with the sealant, allowed it to cure for several days, and finally wrapped the joint in insulating tape for additional strength. Insulating tape has low heat resistance, but the fiberglass and sealant layer provide sufficient thermal insulation. When assembling the apparatus again, I first inserted the adapter into the condenser, then asked my colleague to carefully insert the adapter into the flask and secure the condenser in the stand - I no longer trusted myself not to break it. My colleague succeeded, although he was also nervous. This time, the condenser stayed sealed, and the synthesis proceeded successfully. Later, I realized that such reinforcement could have been applied **before** the joint broke - coating the joint with liquid glass, wrapping it in fiberglass, sealing it, and reinforcing it with tape. This is not a perfect solution, but it would reduce the chance of breakage. Exhausted, I finished the auxiliary work the next day and began planning a new synthesis. That evening, the project manager called and told me to stop working on this compound - he had other plans for me. In the end, the condenser repair was unnecessary. Even the narrow condenser would have been sufficient for the last synthesis, albeit with slightly lower yield. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

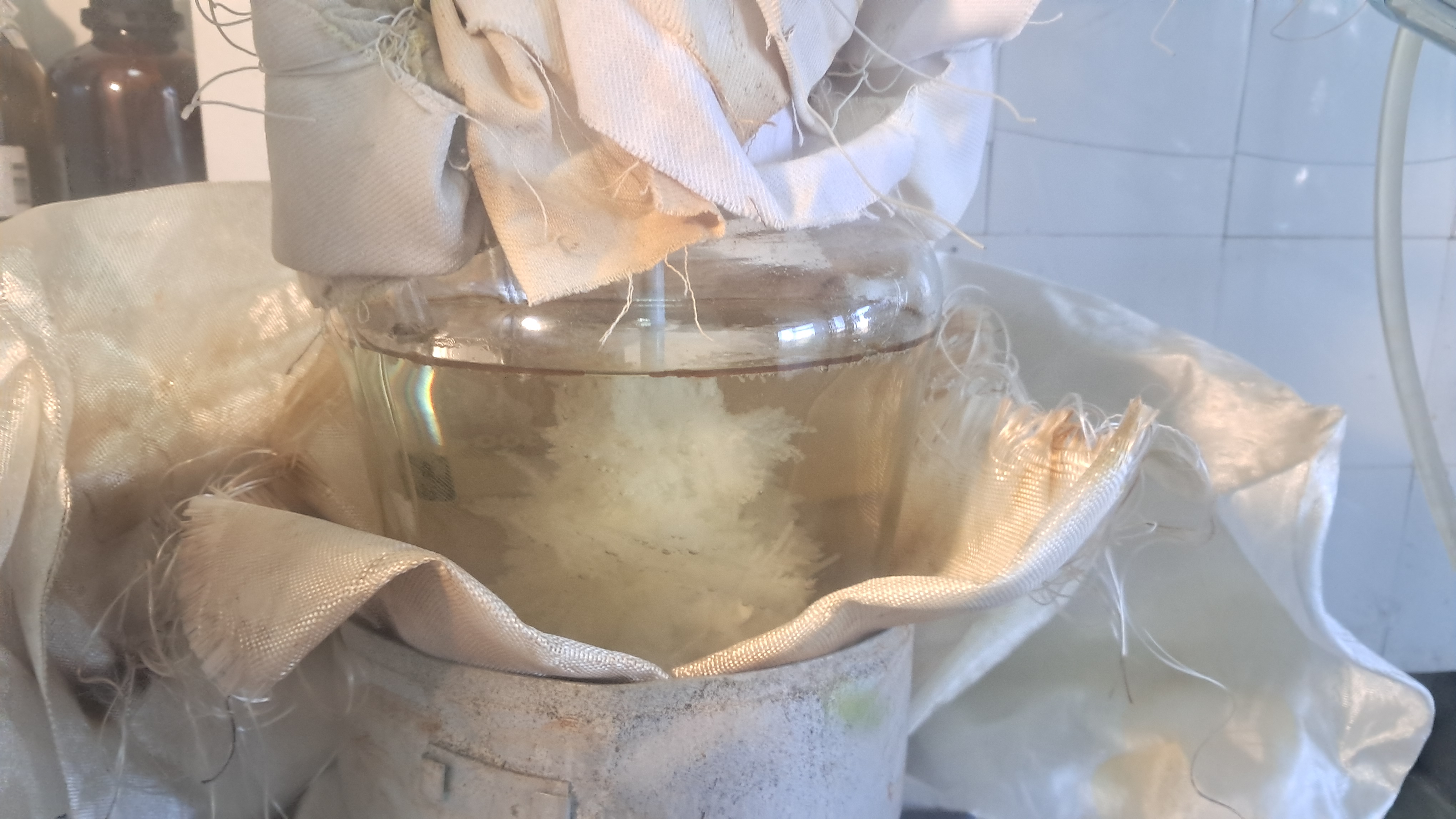

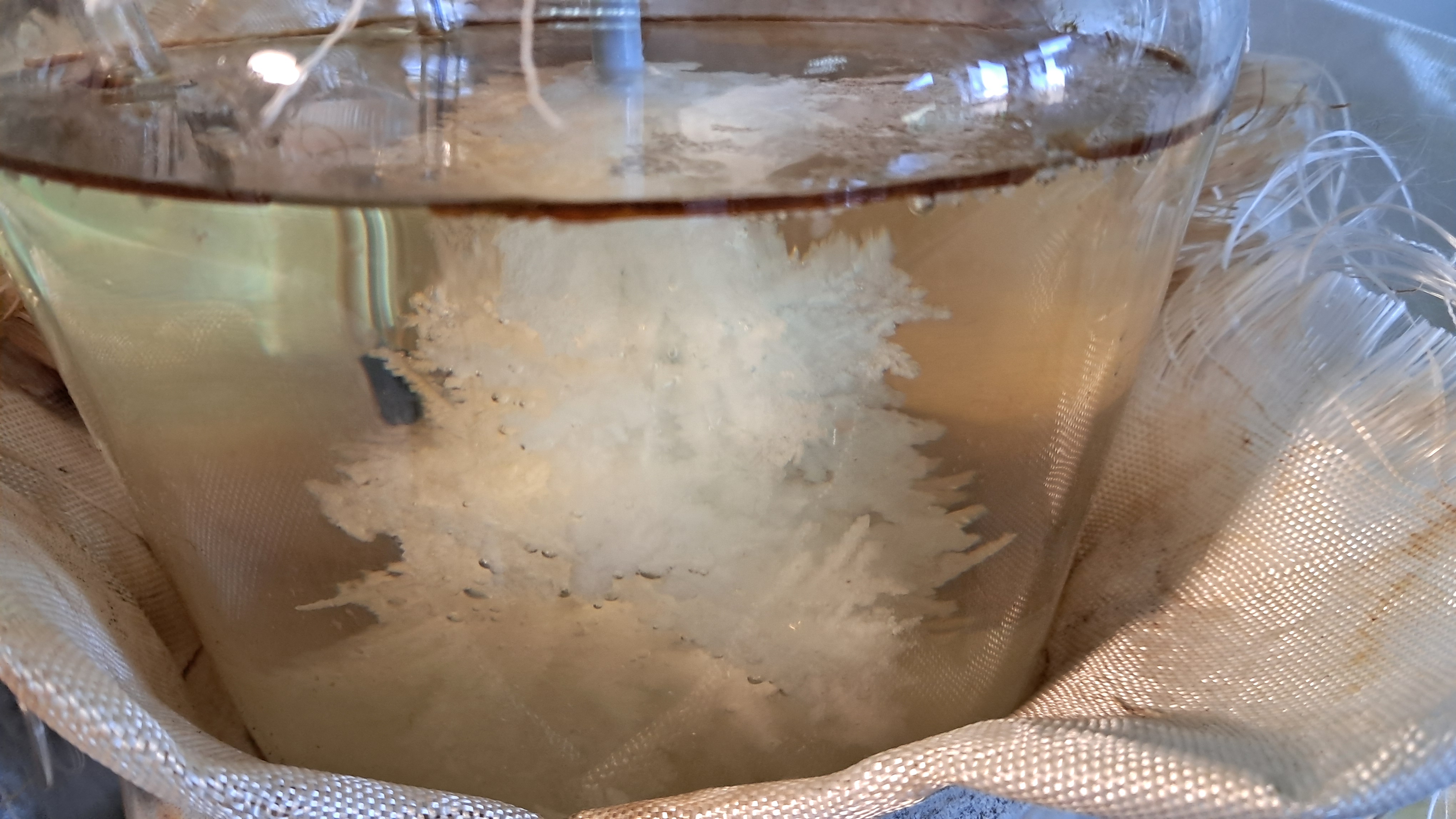

To avoid ending on a somber note, here are the photos of crystals of one of the components of the reaction mixture that formed on the stirrer.

Чтобы не завершать наш рассказ на грустной ноте, предлагаю фото кристаллов одного из компонентов реакционной смеси, которые образовались на мешалке. |

|

|

|

|

|

|

|

|